SUBJECT VEHICLE: 2006-09 Chevrolet TrailBlazer.

RELEARN PROCEDURE? Yes, see reset procedures.

SPECIAL TOOLS NEEDED? Yes, a TPMS Activation Tool (P/N J – 46079) may be used in place of increasing or decreasing the pressures to enable the sensor during reset procedures.

The tire pressure monitoring system (TPMS) on the 2006-09 Chevrolet TrailBlazer warns the driver when a significant loss of tire pressure occurs in any of the four tires, and allows the driver to display the individual tire pressures and their locations on the Driver Information Center (DIC) while the vehicle is being driven.

The TPMS uses the Powertrain Control Module (PCM), Body Control Module (BCM), Instrument Panel Cluster (IPC), the DIC, and Endgate Module (EGM) on models with power sliding rear roof or Liftgate Module (LGM) on all other models, a Radio Frequency (RF) transmitting pressure sensor in each wheel/tire assembly, and the serial data circuit to perform the functions of the system.

NOTE: When the wheels have been rotated, or a tire pressure sensor or EGM/LGM has been replaced, you must retrain the tire pressure sensor. See reset procedures.

When the vehicle is stationary, the sensors go into stationary mode. In this mode, the sensors transmit once every 60 minutes to minimize sensor battery consumption. As vehicle speed increases, the sensors go into drive mode, in which they transmit once every 60 seconds.

NOTE: The sensors’ pressure accuracy is about 1 psi (7 kPa) at temperatures from 14 to 158 degrees Fahrenheit (-10 to 70 degrees Celsius).

The EGM/LGM receives and translates the data contained in each sensor transmission, then sends the tire pressure and tire location data to the DIC. When the TPMS detects a significantly under-inflated tire pressure, a “CHECK TIRE PRESSURE” message is displayed on the DIC and the low tire pressure indicator is displayed on the IPC. The EGM/LGM has the ability to detect malfunctions within the TPMS. Any malfunctions detected will cause the DIC to display a “SERVICE TIRE MONITOR” warning message.

[PAGEBREAK]

TPMS warning indicators

When TPMS detects a significantly under-inflated tire pressure, a “CHECK TIRE PRESSURE” message is displayed on the DIC and the low tire pressure indicator is displayed on the DIC. Inflate tire(s) to the specified pressure. The DIC will display the “SERVICE TIRE MONITOR” message if one or more of the tire pressure sensors has malfunctioned or if all of the sensors have not been programmed successfully. If the warning indicators are still on, there is a problem in the TPMS. See appropriate manufacturer service information.

When the tire pressure warning light illuminates and a warning message appears, immediately check the air pressure of all the tires and adjust to the specified pressure. Drive the vehicle above 25 mph (40 km/h) for a few minutes. If the warning indicators are still on, there is a problem in the TPMS. See appropriate manufacturer service information.

Reset procedures

NOTE: When the wheels have been rotated, or a tire pressure sensor or EGM/LGM has been replaced, retrain the tire pressure sensor. When the tire pressure warning light illuminates and a warning message appears, immediately check the air pressure of all tires and adjust to the specified pressure. Drive the vehicle above 25 mph (40 km/h) for a few minutes. Ensure warning indicators go out.

NOTE: If this procedure is performed following replacement and reprogramming of the Liftgate Module (LGM), the DIC may display a low tire pressure fault and all tire pressures read 0 psi. If this problem occurs, contact the vehicle manufacturer for the repair procedure.

NOTE: Once the TPMS learn mode has been enabled, each of the sensor’s unique identification (ID) codes can be learned into the EGM/LGM memory. When a sensor ID has been learned, the EGM/LGM sends a serial data message to the BCM to sound a horn chirp. This verifies the sensor has transmitted its ID and the EGM/LGM has received and learned it. The EGM/LGM must learn the sensor IDs in the proper order to determine correct sensor location. The first learned ID is assigned to the left-front location, the second to right-front, the third to right-rear, and the fourth to left-rear.

NOTE: Each sensor takes a pressure measurement sample once every 30 seconds while in stationary mode. If the tire pressure increases, or decreases by more than 1.6 psi (11 kPa) from the last pressure measurement, another measurement will occur immediately to verify the change in pressure. If a pressure change has indeed occurred, the sensor transmits in re-measure mode. When the EGM/LGM receives a re-measure mode transmission while in learn mode, it will assign that sensor ID to the location on the vehicle relative to the order in which it was learned.

After performing the procedure below, always test-drive the vehicle above 25 mph for at least two minutes before viewing tire pressures on DIC.

NOTE: In the following procedure, a TPMS Activation Tool (J – 46079) may be used in place of increasing/decreasing pressures to enable the sensor. To use, place the activator antenna against the tire sidewall close to the wheel rim at the valve stem location, then press and release the ACTIVATE button. If TPMS Activation Tool (J-46079) is used, and the vehicle is having trouble entering relearn mode, check the batteries in the activation tool. Low batteries may allow some functions to work, but not allow the vehicle to perform the learn function. When the internal battery is fresh (fully charged), the indicator is “full” or all dark. When the battery is depleted, the indicator shows “empty” or all light.

1. Turn the ignition switch to the ON position with the engine off. Apply the parking brake.

2. Turn the headlight switch from OFF to parking lamps four times within four seconds. A double horn chirp will sound and the low tire pressure indicator will begin to flash to indicate the learn mode has been enabled.

3. Starting with the left-front tire, increase or decrease the pressure for eight to 10 seconds, or until a horn chirp sounds. A horn chirp may occur before the eight- to 10-second pressure increase/decrease time period has been reached, or up to 30 seconds after the eight- to 10-second pressure increase/decrease time period has been reached.

4. After the horn chirp has sounded, proceed as in step 3 for the next three sensors in the following order: right-front, right-rear and left-rear.

5. After the left-rear sensor has been learned, turn the ignition switch to the OFF position to exit the learn mode. Adjust all tire pressures to specification.

[PAGEBREAK]

Demounting/mounting procedures

CAUTION: The tire should be demounted from the wheel using the tire changer manufacturer’s instructions. Use the following information to avoid damage during demounting/mounting.

NOTE: If the vehicle’s tires are replaced with those not having a TPC Spec number, the TPMS may give an inaccurate low pressure warning. Non-TPC Spec tires may give a low pressure warning that is higher or lower than the proper warning level achieved by TPC Spec numbered tires.

NOTE: When the wheels have been rotated, or a tire pressure sensor or EGM/LGM has been replaced, retrain the tire pressure sensor. See reset procedures.

Tire pressure sensor

CAUTION: DO NOT inject any tire liquid or aerosol tire sealant into the tires, as this may cause a malfunction of the tire pressure sensors. If any tire sealant is noted upon tire demounting, replace the sensor. Also remove all residual liquid sealant from the inside of the tire and wheel surfaces.

Removal

1. Raise the vehicle on a suitable support. Remove the tire/wheel assembly from the vehicle.

2. Demount the tire from the wheel following the tire changer manufacturer’s instructions while paying special attention to the following to avoid damaging the tire pressure sensor:

• Place the sensor’s cap and valve on a dry, clean surface after removal. The cap is aluminum and the valve is nickel-plated to prevent corrosion. DO NOT substitute a cap or valve made of any other material.

• Position the bead breaking fixture 90 degrees from valve stem when separating the tire bead from wheel.

• Position the mounting/demounting head so the tire iron (or pry bar) can be inserted slightly clockwise of the sensor body when prying tire bead up and over the mounting/demounting head.

• Using a tire machine, rotate the tire/wheel assembly clockwise when transferring the tire bead to the outside of the wheel rim.

• Repeat items for the inner bead.

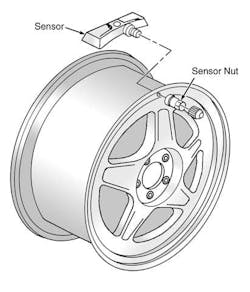

3. Remove the tire pressure sensor nut. See Figure 1.

4. Remove the sensor from the wheel hole.

5. Remove the sensor grommet from the valve stem.

Installation

1. Clean any dirt or debris from the grommet sealing areas. Install the grommet on the sensor valve stem.

2. Insert the sensor in the wheel hole with the air passage facing away from the wheel.

3. Install the sensor nut, and position the sensor body parallel to the inside wheel surface while tightening the nut to 62 in.-lbs. (7 N.m).

4. Before installing the tire on the wheel, note the following items to avoid tire pressure sensor damage upon tire mounting:

• Position the mounting/demounting head at a 180-degree angle from the valve stem.

• Position the bead transition area 45 degrees counterclockwise of the valve stem.

• Using a tire machine, rotate the tire/wheel assembly clockwise when transferring the tire bead to the inside of the wheel rim.

• Repeat items for the outer bead.

5. Install the tire/wheel assembly on the vehicle. Retrain the tire pressure sensor. See reset procedures.

NOTE: A service replacement tire pressure sensor is shipped from the manufacturer in the OFF mode. In this mode, the sensor’s unique identification code cannot be learned into the EGM/LGM’s memory. The sensor must be taken out of OFF mode by spinning the tire/wheel assembly above 20 mph (32 km/h) for at least 10 seconds in order to close the sensor’s internal roll switch. ■

Information for this column comes from Mitchell 1’s “Tire Pressure Monitoring Systems Guide” for domestic and import vehicles through 2013. Headquartered in Poway, Calif., Mitchell 1 has provided quality repair information solutions to the automotive industry for more than 80 years. For more information, visit www.mitchell1.com.

For more TPMS articles, see:

Special switch resets warning thresholds on Prius