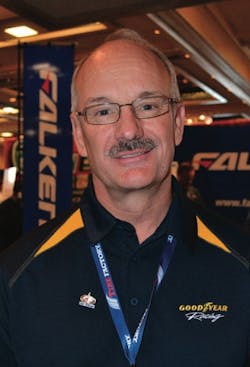

What metrics should tire dealers track to make their mechanical work more profitable? Bob Fox, owner of J&J Tire Factory in Helena, Mont., answered that question during a presentation at the Tire Factory Inc.’s annual dealer meeting last February. (On May 28, Tire Factory announced it joined Point S, an international network of independent tire and car service dealers; details are on page 12 of this issue of MTD.)

“With online tire sales and tires becoming a commodity that can be bought anywhere, we need to figure out a way to stay in business,” he says.

Adding or increasing mechanical work is a logical step for tire dealers. Excerpts from Fox’s presentation, in which he shared the benchmarks he uses and how he tracks progress, follow.

What to track

Car count. How many know their daily car count? How many actually track their vehicle inspections? What is your markup percentage on parts per month? Those are the things you need to know. I’ve looked at 20 Tire Factory stores that do both service and tires and found that the average store has 26 cars per day.

At J& J Tire, the average benchmark per service advisor is six cars per day. What I see in a lot of stores, and what we did in the early years, is to have so many cars and so much business that we just got people in and out as quickly as possible, do a little job and out the door they go, never taking the time to check the vehicle thoroughly. Slow it down so you have time to sell your customer profitable business.

Average sales per invoice. Out of those 20 stores the average dollar amount per invoice is $220. The benchmark that we are working toward is $350 per invoice.

We allow a lot of business to walk out the doors that we don’t take the time to sell.

Average alignments per month to percentage of tires. Let’s say the 20 stores I looked through are doing on average 60 alignments per month. That is, for every four tires you sell, 50% of the cars are getting an alignment.

One of the things we’ve done is to offer free alignment checks any time a person buys two or more tires. You find with a free alignment check that not many vehicles are within specs. It gives you a chance to get the car in, inspect the front end parts, find other work, and if they just need an alignment, you get to charge for that.

Service advisor to tech ratio. You should have one service advisor to two auto technicians. You’ve got to give your service advisors time to price, call the customer, sell it, or have it written down so they know what it costs to fix something. If you can’t give the customer a price, they might go down the street and get the price from somebody else.

Net profit. Three years ago, Jim Murphy (leader of Tire Factory’s Top Flight peer group) asked how many of us would like to have net profit of 20%. I didn’t have a clue what my net profit percentage was. The benchmark is 19% net profit. I would love to have that.

In the 20 Tire Factory stores I audited there was an average of $1.7 million of business per year. That would give them $170,000 of net profit per year. If you hit that benchmark of 19% you would be at $300,000 per year.

[PAGEBREAK]

How to track

Billable hours. Your labor is a commodity. If you have a technician working eight hours a day, you have eight hours you need to sell every day. A good comparison is you have eight tires in stock. If you didn’t sell any of them, the next day you still have eight tires to sell. Compare this to your labor inventory. If you didn’t sell that labor the day before, all of that labor you’ve lost, you’ll never regain it. Your service advisors need to fill that.

Track techs’ time. You need to track three things when you are tracking technicians’ time. The first is how many hours are they are in the building. Track how many of those eight hours they are working on cars. Maybe they worked on cars for six hours. So the second thing you track is how many hours you billed for those six hours that they worked on a car. It’s really an eye-opener.

I always paid by the hour because it was simple. Then we switched to production pay for our technicians. We had a nice scheduling system but the techs complained they had too much work. Then we put them on production pay and after about a month my two technicians came to me and told me I was not taking enough work in. We were taking in the same amount of work we did before. They said you take it in and we’ll get it done. My sales on service work really improved, too. You need to track this daily, weekly and monthly.

A lot of dealers pay by the hour or do a flat rate. Some just pay a percentage of flat rate. Say they charge $100 an hour; they might pay their technician 30%. If the technician is performing 100% of the time, he’s going to make $30 an hour. The problem is if you need to make more money in your shop and you raise your hourly rate, you automatically give your technicians a raise. We have a guaranteed hourly rate but depending on their efficiency they can earn more money per hour.

So we track the hours they are in the building, the hours they are working on a vehicle, and the hours we are billing for when they are working on a vehicle. For instance, if they are scheduled for 40 hours a week, and you sell 30 hours a week and they do that work in 25 hours, they are making more money. But if they are in the building for 10 more hours, what are they doing? And if they don’t have the work then why aren’t your service advisors selling the work if they can do it faster?

Parts to labor ratio. For every dollar of parts you sell you should be billing one dollar of labor. If parts sales in your store are $15,000 per month, you should have $15,000 worth of labor billing. If you’re $15,000 in parts and $7,000 in labor, somewhere your labor is disappearing. You’re not charging for it.

Measure vehicle inspections. Every day we go through invoices and measure the cars that get a full inspection. Our benchmark is 75% of the vehicles that come in get a vehicle inspection. If you don’t track your inspections, the next thing you know they’re not being done consistently. And those inspections create the labor of your future.

Price all the work. The Traction program (Tire Factory’s point-of-sale system) prices all the work. You select the part and it automatically marks it up in your matrix. You look up the labor, add it and try to sell it to the customer. If they don’t want to buy it you select decline. The customer could come in two months later and want to do that work and all you have to do is click undecline and order the part.

Last year 5,500 cars came through J&J. We wrote up $2.4 million worth of work that was declined, but it’s in our database.

Parts markups. Use the parts pricing matrix in Traction and other POS programs. Our benchmark per markup on parts is 50%. I audit this every day because you’ll find that if you don’t audit it, you could have some of your top salespeople, who become everyone’s best buddy, discounting. You don’t give the money away if you audit your invoicing.

Billable fees. There are several ways to capture shop supplies, environmental and tire disposal fees. We add 4% on top of our hourly labor rate for shop supplies. For environmental we add $2 for every fluid package. For tire disposal we charge $2.50 a tire. We used to just give all that away.

In Top Flight peer group discussions, dealers say they can’t charge these fees in their area. You really can. The person stopping you is yourself or your employees on the counter.

We started out where I put 1% on labor, and I said if the customer complains write it off and say it will be on the next one. Well, we’re at 4% and nobody complains. On average out of those 20 stores we collect $20,000 a year per store. Some of those stores in our Top Flight group are collecting $50,000 a year in shop supplies and it goes right to your bottom line. It’s something you gave away before.

Fox was one of four dealers who discussed how they are unlocking the dollar value of mechanical services at the Tire Factory annual meeting. The others were Don Fowers of Clearfield, Utah; Ben Millar of Canby, Ore.; and John Roemer of Missoula, Mont. ■