Modern Tire Dealer has partnered with AG Tire Talk to provide answers to the insightful questions farm tire dealers have about farm tire technology. This is the ninth in a series, which is designed to help agricultural tire dealers better connect with their customers. A trending question followed by an abridged version of the answers will appear in our Commercial Tire Dealer section every other month; for the complete answers, check out www.agtiretalk.com!

QUESTIONS: What off-season storage and pre-season preventative maintenance steps should growers take to reduce downtime? What is best way to measure tread depth?

James Crouch, national agriculture product manager, Alliance Tire Americas Inc.: Tires are so durable in the field that it’s easy to forget they can be damaged if they are stored incorrectly. The big hazards are letting them get out of shape and exposing the rubber compound to degradation.

The best way to store tires is standing up. If you stack them, be sure not to put smaller-diameter tires on the top of the pile—they can damage the sidewalls of the tires below them. A good rule is to avoid putting a tire on a stack that doesn’t cover most of the sidewall area of the tire below it.

If your tires are mounted when you store them, overinflate them by 5 or 6 psi for storage to help them retain their shape over the off-season.

Rubber compounds are susceptible to damage from hydrocarbons, so keep them away from gas, diesel, oil, paint, solvents and mechanical fluids like hydraulic or brake fluid. They can also be weathered by exposure to UV, so keep stored tires out of direct sunlight.

Ozone can also degrade compound, so don’t store tires near electric motors, welders or transformers, which all create ozone as they operate.

As you get ready for the growing season, inspect your tires carefully. Make sure you don’t have any nails or other objects wedged into the tire (you’d be surprised what can have escaped your notice). Check sidewalls for blisters that indicate separation or impact damage, and for slashes or cuts that could threaten the integrity of the casing. Look over your tread for wear, chunking or cracks.

And, of course, adjust your inflation pressure to the proper level for the load and speed you will be operating at.

Invest in a tread depth gauge. They’re not expensive, and they’re easy to use.

All you have to do is rest the feet of the gauge on your tread lugs or blocks and extend the probe into the space between the lugs. The key is to do it several times at different places in each tire. That way, you’ll pick up indications of uneven wear, which are important for determining whether your inflation pressure has been correct, and whether you need to rotate your tires more frequently.

Examining tread depth is important in determining whether your tires are worn out.

Albert Sumera, Continental commercial specialty tire technical solutions engineer, Continental Tire the Americas LLC: As with any other tire that will not be used for a period of time, agriculture tires must be kept in clean, dry conditions and ventilated premises away from direct sunlight.

They must be kept away from any source of ozone, for example an electric motor or transformer; away from chemicals, solvents, and hydrocarbons that may affect the nature of the rubber; and away from any objects that may pierce the rubber (sharp or pointed metal objects or tools). They should also be stored away from flames or hot objects.

Tires should be stacked if mounted to avoid damage due to tension or compression.

If mounted on a vehicle, de-ballast them as much as possible and over-inflate by 0.5 bar (7 psi) versus the operating air pressure used.

Before the start of operations next season, check the physical condition of the tires and adjust to the correct operating air pressure.

Tread measurement should be made on properly mounted tires. Tires normally grow after first inflation. This effect is very significant the first few hours and can go on for the rest of tire life in minimal dimensions.

Recommendation for precise measurements at “new” condition:

- Set air pressure to 2.0-2.5 bar (29-36 psi) at mounting.

- Run the tires for a few miles on road at max tractor speed.

- Adjust the air pressure to the operating air pressure.

- Measure the tread depth the next day (24 hours later).

We recommend measuring the tires every 500-1,000 hours, but the first measurement after fitment should be done earlier. During the first 100 hours the wear rate is generally higher, which is normal for all types of tires.

Dave Paulk, manager of field technical services, BKT USA Inc.: As spring tilling, spraying, and planting begins, farmers are reliant on good tires with minimal downtime. At this point of the year, downtime costs time and money — but before equipment is stored for the winter, there are things that can be done to minimize tire and equipment problems in the spring.

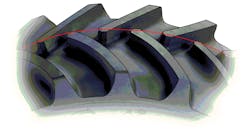

1. Tires should be checked for cracks, cuts, bulges, or any other type of visible damage. If there is any damage or possibility for failure, this gives time to replace or repair tires before they are needed again. Be sure to check tread depth. If the tire has less than 20-25% tread left, the tires may need to be replaced sometime during the next year. This gives the farmer time to budget for new tires. There are several ways to measure tread depth. An OTR tread depth gauge can be used and bought through suppliers that cater to the tire business. Also, a straight edge with a ruler can also be used by laying the straight edge over the top of the lugs. Measure from the base of the tire to the straight edge with the ruler as close to the center of the tire as possible.

2. Make sure lug nuts are tightened to correct specifications. Check the bolts for wheel weights to ensure they are tight.

3. Inflate tires to the maximum recommended inflation pressure by the manufacturer for storage. Ambient air temperatures can cause air pressures to move up and down during the winter months when the equipment is not in use. Air pressures generally decrease in cold weather, causing the tires to go flat if they are not inflated enough. If tires go flat during the winter, the rim can damage the sidewalls by sitting on them. It is a good idea to check tires periodically while the equipment is stored to ensure they don’t go flat. When taking the equipment out for use after storage, set air at correct recommended pressures to carry the weight of the tractor and equipment. This will ensure the tire is not damaged and will minimize soil compaction. Do not drive on flat tires.

4. Make sure tires are clean before storage. Clean the mud, sticks, and rocks from lugs and remove mud from the rim and weights (if wheel weights are used). In general, it is a good idea to store the equipment clean. When it is used again, it is ready to go.

5. If possible, it is best to store equipment inside in a cool and dry place. This keeps the sun, wind, rain, and snow from weathering the tractor and the tires. Ozone in the air and sunlight can cause rubber to age prematurely. It is best to keep rubber products away from electric motors, oils, fuels, and resins.

If the tractor will be sitting for several months or more, it is best if the tires are not parked on rocks or asphalt. Rocks can damage tires if they lose air pressure. Also, asphalt is an oil-based material that will cause rubber to deteriorate over time.

If the tractor must be left outside, cover the tires with a waterproof tarpaulin to avoid contact with ultra violet rays and bad weather.

Scott Sloan, ag product manager/global LSW, Titan International Inc.: Ag tires are designed to withstand the usage conditions of their respective application, but in order to achieve their full performance potential, they must be maintained appropriately, which includes the condition in which they are stored in the off season in order to minimize the chance of experiencing an ozone/weather cracking condition over the winter months when the equipment is inactive.

Rubber compounds that are exposed to the atmosphere are formulated to resist deterioration caused by ozone. It may be hard to believe, but the rubber compound properties constantly evolve due to their service and storage conditions. Improper storage can result in various tire conditions to develop, including weather/ozone cracking — also known as veneer cracking — dry rot and weather checking if tires are not stored properly when not in use.

Ozone/weather cracking appears as a condition where small cracks/checks develop sometimes very quickly. This condition can appear from normal aging or late in its service life. It typically appears in higher stress areas on the tire near lettering of between the lugs.

In order to help avoid potential tire degradation, maximize tire performance, and ultimately prevent premature removals, we generally recommend a few things to help minimize these types of conditions. If you think about what causes the condition, the surface of the tire or rubber with tension or stress and exposed to sources of ozone and UV light, the common sense approach would be to eliminate those.

In a perfect world the best-case scenario would be to block equipment off the ground to remove the load and let air out of the tires to relieve the stress on the tire surface. In addition, the unit should be stored in a covered environment away from sources of ozone, which would include electric motors/machines, engine exhaust, welding equipment, battery chargers, transformers, and mercury vapor lamps. Other equipment that may produce sparks or electrical discharges should also be avoided. Covering the tires with an opaque wrap will eliminate the chances any UV light to attack the surface of the tires.

I realize that it seems like a lot of work, but if you follow any of these suggestions or you realize you are accidentally exposing your tires to harmful elements, you can take whatever counter measures to minimize the risks.

Typically, tread depths on ag tires are taken across the center of the tire between the nose of the lugs. Using a depth gauge is the best way, but you can use a ruler or tape measure with a straight edge to get the same measurement.

Ken Brodbeck, vice president of technology, Precision Inflation LLC: At the end and beginning of the season, check tire pressure! Inflate to recommended plus 2 to 3 psi for weather changes.

Check for any cuts or breaks in the tire tread, shoulder, sidewall and bead area. Is there irregular tread wear? This may stem from over or under-inflation!

Store tires in a dark and electric motor/welder-free area. Sun and ozone kill tires. Keep petroleum-based liquids and grease away from tires.

Reset tire pressure at the beginning of the season for the machine’s heaviest load, such as a large front fold planter. At a minimum, check tire pressure once per week during use.

If you need to measure tread depth, choose the worst wear location, lay a straight edge across two tread bars and measure to the base of the tire with a ruler.

David Graden: operational agriculture market manager, Michelin North America Inc.: Over the years, I have seen many methods producers have used to either prolong the life of their tires or prevent the effects of winter storage on the following season. These would include parking their machine (tires) on wood or concrete blocks, taking weight off of the tires by raising the machine off the ground, covering tires with a sheet or tarp, increasing the air pressure to maximum psi, etc. The reality is there are only a couple of simple actions a machine owner should take to help maximize the life of their tires and ensure optimum performance the following season.

After harvest season has come to an end, your machinery has been washed and you are ready to button up things for winter. I recommend parking your machine in a cool, dry place. Washing your machine thoroughly will show evidence of any fluid leaking throughout the storage period. Additionally, make sure your tires aren’t sitting in chemicals, hydraulic fluid, fuel or oil. Petroleum-based fluids will eat rubber and cause your tires to crack at the contact area.

Next, raise the air pressure of your tires to the maximum air pressure recommended on the sidewall of the tire.

As the ambient temperature falls, so does the psi in your tires, in addition to the natural loss of air pressure over time.

When you return to use your machine and pull out of storage for the season, reset your air pressures to the recommended psi. Your tire manufacturer representative should be able to assist you with this.

If you wanted to keep an eye on your tread and track my thoughts here, Michelin recommends taking tread measurements at the center of the tire, at the lug nose. If your tire pressures are set to recommended psi for the weight carried, your tires should wear nice and evenly across the face of each lug. If your tires are not wearing this way, you could have a mis-mounted tire or have a mechanical issue causing that tire to wear unevenly. Consult your manufacturer’s rep for recommendations or diagnostic.

Norberto Herbener, OE applications engineer, Trelleborg Wheel Systems Americas Inc.: After a hard season and harvest complete, it is now time to take a well-deserved break until the next growing season. This time of the year allows us to perform maintenance operations neglected during the growing season due to lack of time and prepare the equipment for a hassle-free performance next season.

It is important during this time to check your tires, as they are a key component of your operation. There are several points to consider when checking tires during the off season.

1. Check for external damage that could compromise the tire’s structural integrity or performance. For example; nails, deer antlers, deep cuts, missing parts, etc. If any external damage is found, consult with your tire expert if you think it will affect the performance of the tire.

2. Check for correct bead seating on the rim and potential tire to rim slippage. If any issues are observed here let your tire expert assess the situation and correct if necessary.

3. Check the bead area for material between the bead and the rim. If anything is found, be sure to remove it. If it’s difficult to remove, let your tire dealer do it for you.

4. Check the tire for signs of any uneven or excessive wear pattern that can be related to incorrect tire inflation pressure, incorrect tire size selection (that differ from a correct lead value depending on the tractor inter-axle ratio), excessive tire-to-soil slippage or damage/wear on steering components.

5. Check the height of the lugs and replace the tires if the lugs are below 20-30% of their original height. The original measurement can be found in the tire manufacture data-book and web page.

It is always recommended to store the equipment inside a shed and away from direct sunlight. Direct and prolonged exposure to sunlight can create superficial cracking and potentially dry out the tire.

If possible, lift the equipment and place it on stands to allow the weight of the load to be released from the tires. You can also increase the inflation pressure so the tire maintains its round shape as much as possible. Take into consideration that no tire is 100% air tight, so the tires will lose some air over time. Once the new season starts, recheck and adjust the inflation pressure to the recommended values depending on the equipment and application.

If the tires are removed from the equipment to be stored during the off season, for example a floater set for sprayers, be sure to store them standing upright. Clean the tires as much as possible to remove dirt and other debris. Don’t allow the tires to come in contact with petroleum-based products or solvents.

Bradley Harris, manager, global agricultural field engineering, Firestone Ag Division, Bridgestone Americas Tire Operations LLC: Before planting begins, farmers should perform a standard equipment check to make sure tractors, tillage and planters are in good working order. Checking oil, hoses and fittings is typically at the top of mind — but we can’t forget about tires. Firestone Ag has created a seven-step Tire Check list to help farmers quickly but effectively check their tires this off-season so they can maximize up-time when planting and growing seasons arrive.

The Firestone Ag Tire Check list provides seven steps that help to identify signs of tire wear. Regularly checking tires can help prevent and avoid more time-consuming problems in the field, therefore increasing the tires’ lifespan and a farmer’s profitability. ■

Farm tire warranties: Review and compare them on Ag Tire Talk

Ag Tire Talk has assembled complete warranty details — and a Radial R-1/R-1W summary — for ag tire brands on its website, agtiretalk.com. The brands highlighted are Alliance, BKT, CEAT, Continental, Firestone, Maxam, Michelin, Titan/Goodyear and Trelleborg/Mitas.

“This new feature supports our primary mission of providing in-depth information on ag tires that helps tire dealers better serve their farmer customers and farmers make informed decisions about purchasing and operating ag tires,” said Ag Tire Talk founder James Tuschner.

During his 28-year career in the tire business, Tuschner said he often saw the need for a simple, yet informative online resource addressing the increasingly complex world of ag tires. Since its launch three years ago, traffic to agtiretalk.com has steadily increased, in part thanks to input from leaders in both the tire and ag industries.

One of the most popular features on Ag Tire Talk is the “Manufacturer Answers” section, in which ag tire manufacturers provide insights into key issues every other month. Modern Tire Dealer runs an abridged version of each issue-and-answers article in its Commercial Tire Dealer section.

To review ag tire warranties, visit www.agtiretalk.com/warranty-stop.