SUBJECT VEHICLE: 2009 Honda Fit.

SENSOR IN TIRE? Yes.

RESET PROCEDURE? Yes (whenever a sensor or a TPMS control unit is replaced).

SPECIAL TOOLS NEEDED? Yes (TPMS Tool AKS06020006 or TPMS Tool ATEQ VT55).

The 2009 Honda Fit’s tire pressure monitoring system (TPMS) consists of a low tire pressure indicator, a TPMS indicator and a TPMS control unit. The control unit monitors all four tires and alerts the driver if there is a change in pressure.

When the vehicle speed exceeds 28 mph, the sensors start to transmit data using a radio frequency signal to the TPMS control unit once every 60 seconds. In this stage, the sensors enter “normal function mode.” When the vehicle is stationary for five minutes or more, the sensors enter into “sleep mode” to save battery life.

Each sensor is in an integrated unit made up of the valve stem, a sensor and a transmitter. The unit is attached to the inside of the wheel around the valve stem. Each sensor has its own ID to prevent jamming by similar systems on other vehicles.

Sensor swap-out

Before you can exchange a sensor, you have to demount the tire from the wheel. Follow the tire changer manufacturer’s instructions. Note that vehicles equipped with TPMS must use wheels that are made for the system or the system will not work properly. Here’s the procedure:

1. Remove the wheel with the bad sensor.

2. Remove the tire valve cap and valve core. Let the tire deflate.

3. Remove any balance weights and remove the tire from the wheel. Do not position the bead breaker of the changer too close to the wheel. Position the rim so the tire changer and the tire iron are next to the valve stem, and will move away from it when the machine starts.

4. Remove the tire from the wheel.

5. Remove the valve stem nut and washer. Remove the sensor with the valve stem from the wheel.

6. Remove and discard the valve stem grommet from the sensor.

Now it’s time to install the new sensor following these steps:

1. Clean the mating surfaces of the sensor and the wheel.

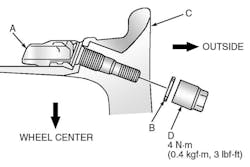

2. Install the sensor and the washer to the wheel and tighten the valve stem nut finger. Make sure the sensor is resting on the wheel (see Figure 1).

3. Tighten the valve nut to 35 in.-lbs. while holding the pressure sensor toward the wheel.

4. Lube the bead sparingly with a paste-type tire mounting lubricant. Position the wheel so the tire machine and tire iron are next to the valve stem and will move away from it when the machine starts.

5. Install the tire onto the rim. Inflate the tire to 44 psi to seat the tire bead to the rim. Adjust the tire pressure to specification and install the valve stem cap.

6. Check and adjust the wheel balance. Install the wheels on the vehicle.

At this point, you’re ready to memorize the pressure sensor IDs.

[PAGEBREAK]

New memories

When a tire pressure sensor or control unit is replaced, the IDs on all four sensors must be memorized by the TPMS control unit. Here’s how the memorization process works (note that TPMS Tool AKS06020006 or TPMS Tool ATEQ VT55 are necessary to perform this procedure):

1. Turn the ignition switch to the LOCK position and wait five minutes for the sensor to enter into sleep mode.

2. Connect the Honda Diagnostic System (HDS) to the Data Link Connector (DLC) located under the left side of the dash.

3. Turn the ignition switch to the ON position and verify that the HDS is communicating with the TPMS control unit.

4. Select “Sensor ID Learning” on the HDS tool.

5. Turn on the sensor initializer tool. Hold it near the valve stem on one wheel and memorize the sensor ID by following the screen prompts on the HDS.

6. Repeat step number five for each wheel until all four sensor IDs have been memorized. When all have been memorized, the low tire pressure indicator will blink.

7. Turn the ignition switch to the LOCK position. Disconnect the HDS from the DTC.

8. Test drive the vehicle at 28 mph or more for at least 60 seconds.

The following procedure locates where the tire pressure sensors are mounted when activated by the TPMS tool. Position the vehicle at least 10 feet away from other vehicles that have TPMS. Let the vehicle sit for at least five minutes to allow the sensors to switch over to sleep mode.

1. With the ignition in the LOCK position, connect the HDS to the DLC. Turn the ignition switch ON.

2. Select “Function Test” and then “Sensor Position Check” on the HDS tool.

3. Follow the HDS screen prompts to turn on the TPMS tool. Use the tool to activate the pressure sensors. Note that if the sensor does not respond to the TPMS initializer, rotate the tire 1/4 of a turn and repeat step five.

4. Check the HDS screen and note the active sensor reception order of all four sensors.

5. Turn the ignition switch to the LOCK position.

A note about the impact of ambient temperature on TPMS since the winter months are here: a temperature change of about 18 degrees Fahrenheit will alter a tire’s pressure by about 1.5 psi. If the outside temperature drops, the tire pressure could decrease just enough to turn on the low tire pressure indicator. After the outside temperature climbs, the low pressure indicator will turn off.

Explain to the customer how temperature changes can affect TPMS. ■

Information for this column comes from Mitchell 1’s ”Tire Pressure Monitoring Systems Guide” for domestic and import vehicles through 2009. Headquartered in Poway, Calif., Mitchell 1 has provided quality repair information solutions to the automotive industry for more than 80 years. For more information, visit www.mitchell1.com.