SUBJECT VEHICLE: 1999 to 2010 Volkswagens — all models except Routan.

COMPLAINT: Applying the brakes at highway speeds may cause pedal pulsation. This may be accompanied by vibration in the vehicle body and shaking in the steering wheel.

CAUSE/SOLUTION: The condition may be caused by improperly machined brakes. The solution may involve machining or replacing the brakes.

Volkswagen drivers may complain of a pulsating brake pedal when applying the brakes at highway speeds. The pulsation may also be felt as a vibration in the vehicle body. Additionally, the steering wheel may shake. The cause may be improperly machined brakes, and the condition may not be felt until several months after the brakes were machined. To correct the problem, follow these steps.

Repair procedure

Remove the wheels and separate the brake calipers from the carrier using factory and/or industry standard approved practices.

Brake disc inspection

A detailed brake disc inspection is needed to determine if the brake disc should be machined or replaced. Inspect brake disc friction surfaces on both sides of the brake disc for:

• severe discoloration (bluing);

• high heat surface damage (raised hard spots); and

• visible cracks.

Brake discs showing any of the above described conditions must be replaced.

Disc thickness measuring

Each brake disc has the minimum allowed thickness cast, stamped or laser-etched into the disc hub.

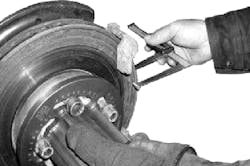

• Measure the brake disc thickness in four locations using factory and/or industry standard approved practices. Measurements must be taken the same distance from the brake disc outer circumference to ensure consistency (see Figure 1).

NOTE: The brake disc must exceed the minimum thickness after the machining process is completed in order to be reused.

Brake disc machining

TIP: Brake discs must be machined in pairs (front axle and/or rear axle).

NOTE: To ensure that a high quality brake disc finish is produced, brake lathe cutting tools must be maintained as directed by the lathe manufacturer.

• Follow the brake lathe manufacturer’s instructions for set-up and machining.

• Wash the brake disc with a soap and water solution upon completion of resurfacing to remove all machining particles.

• Re-measure brake disc thickness in four locations to verify that minimum thickness is still exceeded. If recorded brake disc measurement is less than the minimum thickness, the brake disc must be replaced (refer again to Figure 1).

NOTE: Always replace brake discs in pairs (front axle and/or back axle).

• Measure brake disc lateral run out. Run out must not exceed 0.1 mm.

Drive the vehicle to verify the repair. ■

Written by ALLDATA Editor Ed Dorowski and Technical/Marketing Writer Jeff Webster. Dorowski has 19 years of domestic and import dealership and independent shop experience as a service consultant, ASE Certified Master Technician, Nissan Certified Master Technician, and California Smog Test and Repair Technician. Webster has 20 years of experience as a writer/editor. The database is provided by ALLDATA, a registered trademark of ALLDATA LLC. ALLDATA is a corporate division of AutoZone Inc. The company’s Web site is www.alldata.com.