OPERATION

The signals from the TPMS transmitter are received by the ETACS-ECU (vehicles without Keyless Operation System) or KOS & OSS-ECU (vehicles with Keyless Operation System).

ETACS-ECU or KOS & OSS-ECU vehicles process input signals from each TPMS transmitter as well as vehicle speed signals from the ASC-ECU. It receives the atmospheric pressure signal from ECM, and when the atmospheric pressure is low (such as at high altitude), it calibrates the tire pressure received from TPMS transmitter and makes a judgment of warning. When the road tire pressure is low, a warning signal is sent, causing the TPMS warning light to be illuminated. When the TPMS has problems, the ETACS-ECU or KOS & OSS-ECU sends a warning signal causing the TPMS warning light to flash. The light changes to continuous illumination after flashing for approximately one minute.

For three seconds after the ignition switch is turned to the "ON" position, the ETACS-ECU or KOS & OSS-ECU illuminates the TPMS warning light to check any breaks in the TPMS warning light circuit.

By connecting the scan tool to the data link connector, data stored in ETACS-ECU or KOS & OSS-ECU (data such as tire pressure and tire pressure sensor ID, the alarm status and warning history, etc.) can be displayed and the tire pressure sensor ID can be registered.

NOTE: If the TPMS transmitter is replaced, register the ID codes of all the TPMS transmitters again, including the replaced transmitter, using the scan tool.

TROUBLESHOOTING

Use these steps to plan your diagnostic strategy. If you follow them thoroughly, you will be sure that you have exhausted most of the possible ways to find a TPMS fault.

1) Gather information about the problem from the customer.

2) Verify that the condition described by the customer exists.

3) Check the vehicle for any TPMS DTC.

4) If you cannot verify the condition and there are no TPMS DTCs, the malfunction is intermittent.

5) If there is a TPMS DTC, record the number of the DTC, then perform the TPMS diagnostic trouble code procedures for the DTC.

MEMORIZING THE TIRE PRESSURE SENSOR ID

Register all tire pressure sensor IDs within 20 minutes.

1) Select "4tires ID Reg. (Change tire PRS.)" and start the tire pressure sensor ID registration.

NOTE: If the ID code registration is not finished within 20 minutes, all the ID codes registered in the TPMS transmitter before will be erased. For this reason, the ID codes need to be registered again.

2) "4 SNSR ID Registration Do you want to start? Note Finish ID Registration within 20 minutes." is displayed. Then, press "OK."

NOTE:

- You can start out the following operations from any TPMS transmitter. The tire pressure sensor ID registration has no order.

- On completion of the tire pressure sensor ID code registration, the tire pressure sensor ID code is displayed on the scan tool screen. (Mitsubishi’s latest tool is the M.U.T.-III.)

- The scan tool cannot identify which registered TPMS transmitter is used for each wheel. For this reason, write down the tire number for each wheel when the tire number and ID code is displayed on the scan tool during ID code registration.

- It may take approximately one minute for the ID code to be displayed on the scan tool screen after the tire pressure is reduced.

- If the ID code is not displayed, reduce the tire pressure another 20 kPa (2.9 psi) or more. If the ID code is not displayed yet, rotate the tire to displace the TPMS transmitter, and reduce the tire pressure 20 kPa (2.9 psi) or more again.

- If the ID code cannot be registered for all the four wheels, the ETACS-ECU or KOS & OSS-ECU may be faulty and thus require replacement.

- If the ID code can be registered for one wheel or more, the TPMS transmitter in which the code cannot be registered may be faulty, thus replace that TPMS transmitter.

3) Decrease the tire pressure to 189 kPa (27.4 psi) or less by changing 20 kPa (2.9 psi) or more and register the tire pressure sensor ID code of each wheel to the ETACS-ECU or KOS & OSS-ECU.

NOTE: The TPMS indicator illuminates for tire pressure alarm.

4) "4 SNSR ID Registration Completed." is displayed. Then, select "OK."

5) After one minute or more has passed, correct the tire pressure for all wheels with ignition switch "ON".

6) Check the data list "Registered ID reception, Tire 1, 2, 3, 4" if "YES" is displayed for each tire. When "NO" is displayed, drive the vehicle for approximately five minutes, check the display again. If "NO" is still displayed, register the ID code again.

SENSOR REMOVAL AND INSTALLATION

REMOVAL AND INSTALLATION

WARNING: Certain components of this vehicle, such as TPMS sensors may contain perchlorate materials. Before deployment and/or disposal of these components, review and comply with all applicable Federal, state and local regulations.

CAUTION:

- Ensure valve cap is always in place except when adjusting tire pressure.

- If the valve core and valve cap are replaced, use a genuine replacement part. The valve core is similar to a conventional one but uses nickel plating to avoid corrosion.

- Replace the valve with a new one every five years or when the tire is replaced.

- Do not drop the TPMS transmitter from a height greater than 1 meter (3.3 feet).

- Do not expose the TPMS transmitter to extraneous magnetic fields.

- TPMS transmitter should not be stored at temperatures above 80°C (176°F) or exposed to temperatures above 100°C (212°F).

- If the TPMS transmitter is replaced, execute "Tire Pressure Sensor ID Registration" on the scan tool under the "Special Function".

- Be careful not to damage the TPMS transmitter.

REMOVAL SERVICE POINTS

TIRE BEAD DISENGAGING

CAUTION: Be careful not to damage the TPMS transmitter.

1) Fix the tire on a tire changing machine. Then apply a bead breaking shoe to the shown range to disengage the tire bead from the wheel.

NOTE: For the opposite side, repeat the same procedure.

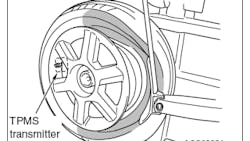

2) Fix the tire on a tire changing machine so that the TPMS transmitter is positioned as shown in Fig. 1.

CAUTION: Do not allow any impact or shock to the TPMS transmitter with a tire lever or tire bead.

3) Use a tire lever to disengage the upper bead.

4) Rotate the tire to disengage the tire bead from the wheel.

5) Fix the tire on a tire changing machine.

CAUTION: Do not allow any impact or shock to the TPMS transmitter with a tire lever or tire bead.

6) Use a tire lever to disengage the lower bead.

7) Rotate the tire in the direction of arrow in Fig. 2 to disengage the tire bead from the wheel.

VALVE REMOVAL

Cut down the entire groove to remove the valve.

INSTALLATION SERVICE POINTS

TIRE BEAD ENGAGING

1) Prepare the tire and fix the wheel as usual.

2) Put the tire on the wheel so that the cross point of the bead with the wheel is approximately 20 cm (7.9 inch) (A) away from the valve, as shown in Fig. 3.

3) Engage the shoe and make sure that 20 cm (7.9 inch) (A) is maintained between the cross point and the valve. The arrow in Fig. 4 shows the direction of rotation of the wheel.

4) Turn the wheel in order to engage all the first side of the tire.

NOTE: The standard shoes can pass over the sensor without damaging it.

5) Put the second side of the tire in position so that the cross point of the bead with the rim is approximately 20 cm (7.9 inch) away from the valve.

6) Turn the wheel to engage all of the second side of the tire.

NOTE: The standard shoes can pass over the sensor without damaging it.