Swimming upstream at OE: Tiremakers look beyond tires

The first of a two-part series on the extracurricular OE activities of tire manufacturers focuses on Continental Teves.

Under increasing pressure from environmentalists, OPEC nations and stockholders, new vehicle makers worldwide are asking their suppliers for help. The task: to manufacture more fuel-efficient, safer, "green" vehicles complete with a nice return on investment.

It should come as no surprise that tire suppliers, who also have bottom line concerns, are already involved in the process of forming strategic alliances with non-tire companies in the interest of offering vehicle makers a helping hand.

Although the commitment among companies varies, some tire makers have reinvented all, or portions of, their companies in the rush to take part in what some are calling a supply chain revolution.

A look at Continental demonstrates the point. You are most familiar with Continental Tire North America or Continental AG headquartered in Charlotte, N.C. and Hanover, Germany, respectively. This is the tire unit of Continental which today is the number one tiremaker in Germany, number one in Mexico and number four in the world.

Next and less familiar to you is ContiTech (Continental's industrial products division) comprised of eight business units and 52 market segments globally. ContiTech produces sophisticated products based primarily on rubber and plastic, including vibration control and air spring components and systems.

The third and most recent addition to the Continental family is Continental Teves which supplies automotive components, modules and systems to virtually all of the world's major vehicle manufacturers from 16 facilities located on four continents.

Continental Teves recently opened an engineering development center in Auburn Hills, Mich., dedicated to serving the OE market in Detroit. Staffed by some 500 employees from all three Continental business units, the new Michigan facility is where it all comes together.

"Our new Continental Teves headquarters in Michigan creates a culture that enables us to design, manufacture and market our tire, brake and suspension systems into total chassis systems," said Dr. Stephan Kessel, Continental chairman.

And here's the kicker. Continental says it has doubled its North American business since 1997 and intends to triple its 1997 level by 2003. According to the company, last year's sales of nearly $10 billion represented a one-year improvement of 35%.

This adds up to what?

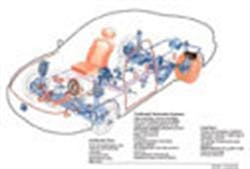

In a word -- bundling! Through Continental Teves, the German tiremaker is bundling various products such as tires, wheels, brakes, brake systems and air suspension systems to vehicle makers who, in turn, integrate them into the vehicle. It's what Continental calls "presenting one face to the customer."

Put another way, the OE customer sees only a single Continental representative. In this manner, Continental's sales teams from the tire, brake and chassis side of the business are united as a single entity and OE customers can source all or part of any system Continental produces.

"This is at the heart of Continental Teves' vision to become a total chassis systems integrator," says Jeff Klei, vice president of sales and marketing for Continental Teves N.A., "to move beyond the role of simply being a tire supplier.

"It's a strategy that began life in 1994 when a joint venture between ContiTech and the Slovakian company Vegum led to the establishment of the Continental Automotive Systems Group. Three years later, Continental won the German Industry Innovation award for its development of ISAD (integrated starter alternator damper). This is a new technology capable of damping engine vibrations, starting the engine noiselessly and generating electric power in the vehicle," says Klei.

"Continental's decision to become more than just a tire supplier to OE customers gained more strength in September of 1998 with the purchase of American ITT Industries, Inc.'s, ITT Automotive Brake and Chassis unit in Frankfurt, Germany," he says. The price: $1.3 billion.

With the stroke of a pen Continental quickly went to work at establishing a new presence at OE. In ITT it now owned the number one producer of disk brakes worldwide and the second-place worldwide producer of anti-lock braking systems (ABS) and brake boosters. Traction control systems (TCS) and electronic stability programs (ESP) were also part of what ITT brought to the party.

As Klei explains it, "Continental today is a supplier of tires, brakes and brake systems, suspension parts and systems, steering components and vehicle structural parts. We are the only company in the world today that brings together such a wide menu of vehicle components from which an OE customer can place an order."

Not surprisingly Continental wants more and so does Klei. "We want to serve the OE customer as a chassis solution supplier," he says. "We want to look more closely at how we can work with our OE customers at stopping a vehicle more quickly and we want to be part of adding value to the customer by providing custom assemblies."

As part of this conversation he talks about such things as the sidewall torsion tire, or intelligent tire. Still in the development stage, this tire has been given a voice by Continental; an electromagnetic voice that reports on the forces the tire is generating. This tire uses the flexing of the sidewall as a sensor that delivers information about these forces as a means to electronically manage the chassis system.

Also mentioned was the ContiPremiumContact tire, not yet available in the U.S. Under normal driving conditions this tire runs slim, providing protection against aquaplaning. But with increased load on the tire during braking, the force on the ground increases by more than 30%, enabling shorter braking distances.

The Continental Teves executive is equally verbal about his company's goal of delivering the 30-meter car. He's talking about a car with a 30-meter (98 feet) stopping distance from a speed of 62 mph at full brake application. "Today, depending on the vehicle, braking distance from 62 mph ranges between 115 to 157 feet," he says. "We want to improve on that number."

Translation: Klei is talking about Continental Teves' ability to assist OE customers. "We can ship, for example, an entire brake corner module (pre-assembled) including the hub, knuckle, bearing, caliper and rotor, all of it tested for lateral runout. Further, every part is engineered to work with the other in an all-out effort to minimize noise and vibration harshness (NVH)."

At Continental Teves, Keil and company are already working with OE customers on 2004 and 2005 vehicles. "We will be looking at such things as suspensions and what we can provide -- ESP, ABS or brake-by-wire. You heard it right, brake-by-wire.

"We are working now with electro-hydraulic brakes that have no booster or master cylinder. Those have been replaced with a pump that features an electrical connection between the brake pedal and the pump. In this way we can fine tune brake feel," says Kiel.

"Further down the road, we will be looking at an electro-mechanical brake system. Here there is no brake tube, no fluid... it is a dry system. A wire runs out to the caliper, which will have an electric motor that squeezes the caliper to achieve braking action. Through the use of this kind of sophisticated electronics we can control every brake corner," says Kiel, who adds that this system is still in the prototype stage.

Next month, Steve will take a look at Continental’s activities with car makers, and what other tiremakers are doing.