Everett David Richards Sr. Dies at 87

Everett David Richards Sr., one of the original Bandag franchise dealers, died July 4, 2017. He was 87.

His son, David Richards Jr., who is president of Canton Bandag Co., in Canton, Ohio, and his sister, Rebecca Gross, sent along this tribute to their father.

Born in Doddridge County–Oxford, W.Va., he was the middle child of seven and the son of a woodcutter. Work ethics were instilled at an early age for if you didn’t work you wouldn’t eat. His family raised everything but sugar and flour, and what they shot they ate.

Everett left home to join the Marines at age 17, but after completing boot camp he was discovered to be under aged and was discharged. He went back home for a while and at the age of 20 met Joy Ann Collins and eventually eloped to Maryland and was married in 1950. Everett eventually moved to Massillon, Ohio, like so many others, to work in the steel mills up north.

He was drafted in the Army in 1951 and spent 18 months in Korea as a forward observer. After an Honorable Discharge in 1953 as sargent he went back to the mills and soon started a family.

In 1957 my dad found out about union strikes and in his case it lasted several months. To create some income, dad started refurbishing bicycles and made them look like new, pin striping and all, but that wasn’t enough. Living on apples and soda crackers and behind in their rent, his neighbor, a big Greek named Jim Costas, ask Everett if he knew anything about tires. My dad said,” No, but I will learn.” That was the beginning of what would be a lifetime experience and knowledge of tires.

He soon hired in at S & S Tire in Barberton, Ohio, and started out learning the hardest work of all, changing semi tires. Of course back then they were all tube type, mostly 20 inch and a few 22s. He eventually was subbed out to work at Dixie Ohio Express (DOX) which was across the street from Goodyear Tire & Rubber Co. Goodyear would use DOX as a test facility because of its size and locality. The work he would do was back-breaking work, changing and repairing 12 to 24 tires per day and monitoring tests for Goodyear.One day four unusual retreaded tires were given him to put on a trailer to run for test. Dad noticed that the retread rubber was only on the top of the tire and not molded over the shoulders as he was accustomed to seeing. He had told me he put them on a trailer going west and it didn’t make Mansfield, Ohio, before one of tires peeled. He made the service call out to change the tire and brought it back. The mate also peeled near Dayton, Ohio, but that service was done near there.

The thing that caught my dad's attention the most was the other two retreads for they stayed on and outperformed anything else he had ever put on -- including new tires.

Shortly afterwards my dad was at S & S tire and overheard a conversation between the owners and a gentleman who was trying to interest them in the very retread that my dad had tested at DOX. He had heard the name “Bandag” for the first time. At the time S & S had their own hot, mold cure system which was prevalent at that time and they would not be interested in another, untried, new process. My father later contacted that gentleman and was very interested in starting up a shop, but had very little capital to do so.

The salesman was Harry Beam. The best I can remember him as built like Colonel Sanders, of Kentucky Fried Chicken fame. He was quite the salesman, very outgoing and passionate about the product. I always had a liking of him and had never met anyone like him or ever since, excluding my father.Everett found two others to partner with and at $1,000 each the four started Bandag of Akron in 1959. At that time there was only the “hot box and stainless steel bands” method to cure. This was before the pressure chamber and envelope days. The buffer was a German manufactured Tru- arc of the type used by the German originator, Bernard A. Nowak.

Of the two other partners, one was an investor friend, Vilas Marsh, also of West Virginia, and a working partner Chris Christianson. Chris worked in the shop with the retreading and some sales, Harry helped with sales and my dad with sales and service. As you may imagine it was rough going in those times. “Bandag, never heard of it,” was many a comment to overcome, but slowly and with much perseverance a small customer base was formed, some industrial solids, but mostly single owner and coal bucket trucks. My father cherished each customer because he knew there were other companies his customers could do business with, but my dad earned their trust and they knew he was honest with them at all times and when failures happened he always made it right and was very responsive. The Bandag product began to earn a good reputation for its long-wearing capabilities and slowly the word spread.

It was early 1962 and a financial crisis occurred with the business and forced its closure. My father strongly believed in the Bandag product and found another financial backer in Carlton B. Coen and in June of 1962, with $ 7,200, franchised Canton Bandag Co. in Canton, Ohio. At this time the pressure curing chamber and envelopes were a major upgrade to the retreading process. He held on to all the older pieces of equipment, some of which is still used today.I started early (at the age of eight) working (trying to help) with my dad. Every morning he would roll all the tires out of the small Amoco gas station to make room for the retreading process. It was then I would “help” to paint the tires with black tire paint with a 4-inch brush before delivery. My mom would be so mad because my clothes would be splattered and ruined from the paint.

Dad had advertised that he would cap any size tire and eventually was taken to court over this claim by one of the major tire makers. It was agreed upon in court, that three tires would be supplied to my dad for retreading by the complainant. One tire was a 4.10/3.50-4, another was a 6.00-6 airplane tire and the last was a 6.00-23 Studebaker tire.Dad was given one week to return with the tires retreaded. The big guys thought they had him. I have the tires still today as a constant reminder you need only believe and trust in the Lord. Dad never backed down when he was in the right.

Dad would work many a nights either emptying the chamber or installing the tires on a truck. Sometimes I would go with him and hold the flashlight so he could finish the job removing, dismounting, remounting, inflating and reinstalling. As I soon would experience, very hard work. Remember these are still tube-type tires with lock rings. I was taught the safe and correct way of disassembly, inspection, cleaning and reassembly of these wheels from my dad. Later, as I grew bigger, we would work well together for we knew what had to be done next without saying a word.

By the time I was 12 I would swing the “duck bill” tire hammer, though I never mastered standing on the tire while it was upon the stand and take the ride down when the tire gave way like my dad could.Dad eventually purchased back the interest of Canton Bandag Co. and was soon told he needed to move, for in a few years Route 30 was coming through, so in 1968 he moved the business location to 6245 Cleveland Ave. S, near East Sparta, Ohio, in a building just built off the road in the strip mines. We rented there for 33 years.

During those years my mom would even help in the retreading (the guys would carry the tires for her from buffer to building station), there were no monorails then. She eventually settled to doing the office bookwork which she did until her death in 1996. All the family at one time or another had worked at retreading. The youngest, Kim, actually retreaded tires for about a year. My younger brother, Dan, was with us three years and eventually was called into the Lord's ministry. My sister, Rebecca, has taken on the roll our mom had and now is assisted by my wife, Candy.

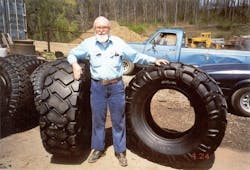

Canton Bandag Co. moved to its new facility of 24,000 sq. ft. in June of 2000, where dad had designed and built a buffer that can do larger tires. Now we have expanded into newer markets such as the only manufacturer of solid antique rubber tires in North America, VIS semi-truck aluminum wheel polishing and specializing in industrial retreading of solid rubber tires, foam-filled tires as well as pneumatic. Oh, yes, we do medium trucks, too!Dad had come in every day as his health permitted and had stopped coming in just before Thanksgiving of 2014. We would always have lunch together. I really missed him then. He was a real trooper and accepted his health challenges with COPD and being in the care facilities that he eventually was committed to. I Timothy 6:12: “Fight the good fight of faith, lay hold eternal life, whereunto thou art called, and hast professed a good profession before many witnesses.” A faith in Christ that all the family enjoys today.

Our customers and the family all miss you. God bless you, dad.

Dave Richards Jr.