The majority of wheel weights are still made of lead. That won’t last forever, however.

Environmental concerns are changing the landscape of this once unchanging and seemingly unalterable market because lead is a highly toxic chemical targeted for reduction by the Environmental Protection Agency.

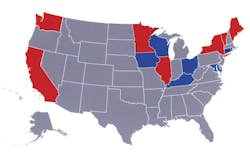

“Across the U.S., individual states and local governments are taking action to remove lead wheel weights from automotive service locations,” says Don Vanderheyden, group marketing manager for Hennessy Industries Inc.

“Initially, many are requiring the use of non-lead wheel weights on fleet vehicles. And, the industry is taking notice.

“Several leading auto makers and tire retailers have made the decision to transition out of lead wheel weights.”

According to the Toxics Use Reduction Institute, a number of European and Japanese automobile manufacturers already have switched to steel or zinc wheel weights:

“While auto manufacturers are making some progress to switch to lead-free wheel weights, the Institute noted that 80% of wheel weights are used by aftermarket businesses such as tire retailers and service stations, and very few of these businesses use lead-free wheel weights.”

Last December, the United States Environmental Protection Agency requested that the industry self-regulate the transition away from lead wheel weights to viable alternatives. A number of companies already offer those alternatives.

[PAGEBREAK]

The players

The following product showcase highlights not only the materials being used as a replacement for lead in wheel weights, but also other trends that have affected the design of wheel weights.

1. IMI: XACTBalance, (800) 233-7086. XACTBalance from International Marketing Inc. is engineered to adjust to changing driving conditions. The weight’s thermoplastic shell houses steel particles that move freely within it.

The movement of the particles adjusts to changing conditions as the tire rotates. As a result, it compensates for changes in the tire’s contact patch. The patented, lead-free wheel weight is attached to the wheel with industrial strength adhesive.

When compared to lead weights, XACTBalance reduces vibration by as much as 60%, according to the company. “Any stationary weight, whether it’s made of steel, zinc or lead, will not reduce vibration as well as a wheel weight that adjusts freely to changing tire conditions,” says President Bob Fogal Jr.

The move away from lead is only one trend that will impact your technicians, however. Fogal says there is also “the ongoing trend to flangeless wheels at the OE level, which requires more tape-on weight application rather than clip-on weights.”

“As that trend continues, the technicians must prepare the wheel surface to apply the tape-on weight. You can’t just put it on over brake dust, grime and film.”

Aesthetically, XACT Balance features a sleek profile and alloy color blend for what IMI calls “a clean look.”

IMI also has developed XACTBalance Truck for commercial tire dealers in North America. The adhesive wheel weight consists of twin thermoplastic chambers of steel particles that balance heavy-duty truck tire and wheel packages. It is compatible with traditional tire balancing equipment.

[PAGEBREAK]

2. Hennessy Industries Inc.: Bada, (800) 688-6359. With several state and local governments taking steps to ban lead wheel weights, Hennessy has been pro-actively providing an alternative, according to Vanderheyden. The Bada steel wheel weight family, which includes weights for three different types of wheel flanges, will be complete by June 2008.

The company says its steel wheel weight is smaller than other non-lead weights, so its center of gravity is “closer to the point where the weight is attached.” The steel weights feature a metallic coating, which enhances the weight’s resistance to corrosion.

Hennessy also produces dry polymer coated and uncoated lead weights. The Aluma-Guard coating completely seals the lead weight and clip to protect alloy wheels (more than 65% of new cars are equipped with alloy wheels, according to the company).

3. 3M: Wheel Weight System, (734) 953-9300. 3M introduced its lead-free, corrosion-free 3M Wheel Weight System at the 2006 Specialty Equipment Market Association (SEMA) Show. The wheel weight is made of a highly flexible and conformable polymer composite material that can be cut to length to meet exact weight requirements, according to Scott Taylor, automotive technology manager for 3M Automotive.

The composite material is made up of both polymers and metals. Recycled materials make up 89% of the composite material.

Compared to other weights, the 3M wheel weight system requires fewer part numbers, says Taylor. “One or two part numbers can take care of a tire dealer’s entire inventory.” The wheel weight material is flexible enough to be cut with scissors, yet tough enough to withstand rigorous durability, weathering, salt spray and “salt fog” testing, he adds.

The wheel weights do not clip onto the wheel; they are attached using 3M Acrylic Foam Tape.

To complement the 3M Wheel Weight System, the company introduced 3M Wheel Weight Surface Prep 1000 for rim cleaning prior to wheel weight application.

4. J.M. Nault: lead weights, (888) 841-0331. J.M. Nault Inc., dba J.M. Nault Wheel Weights Manufacturing, manufactures and distributes lead weights to the automotive aftermarket in North America. Vice President and General Manager Steve Godbout estimates 70% of his lead weights are powder coated.

He says the Quebec-based company has looked into both zinc and steel wheel weights. “We are prepared to make a switch if the market and laws impose it. That said, I’m not convinced that would be the most environmentally friendly way to go."

[PAGEBREAK]

J.M. Nault recycles all its lead weights, paying anywhere from 60 cents to 80 cents a pound for them, or close to $1,500 a ton. In contrast, steel sells for $80 a ton, says Godbout.

“Do you think (the installer’s) going to put steel wheel weights in a pail to recycle, or put them in the garbage? Those steel wheel weights will be put in the garbage.”

In Canada, there is no push to replace lead wheel weights, he adds.

5. Perfect Equipment: QuikStik, (615) 641-1950. Perfect Equipment Inc. offers both clip-on zinc and QuikStik adhesive steel wheel weights in addition to lead weights. The company also sells clip-on steel weights.

“There is growing concern of lead wheel weights and lead’s effects on the environment,” says Scott Flynn, Perfect Equipment’s marketing manager.

“Europe has already mandated the elimination of lead, and the U.S. EPA has requested that the industry self-regulate the transition away from lead wheel weights,” says Mike Pursley, vice president of sales and marketing. “We have customers with national footprints that are being pro-active. It’s not a matter of ‘if’ anymore, it’s ‘when.’”

According to Flynn, the company’s lead-free weights are as strong as conventional lead weights, and can be used with either steel or alloy wheels. Lead is the least expensive wheel weight material right now, he says. Steel and zinc are “very comparable.”

6. Plombco Inc.: Plombco, (450) 371-8800. The Valleyfield, Quebec-based company manufactures both coated and uncoated lead wheel weights and lead-free zinc alloy wheel weights. The polyester-coated lead weights prevent corrosion to aluminum wheels.

“The chemical reaction resulting from the contact between an uncoated weight and the rim will rapidly break down the protective coating of the wheel,” says the company. The result is unsightly discoloration of the wheel around the flange area.

Plombco also sells adhesive lead wheel weights, including CCS Series coated contour adhesive wheel weights. Plombco’s zinc-alloy weights are an environmental alternative to its lead weights. They are available in two lines: one for steel wheels and one for alloy wheels.

[PAGEBREAK]

An environmental push -- 'Green’ organizations emphasize the use of lead-free wheel weights

There are a number of environmentally friendly organizations calling for the elimination of lead wheel weights. The Environmental Protection Agency (EPA) is one of them.

The EPA (www.epa.gov/minimize/leadtire.htm) says the most common exposure to lead comes from breathing lead-contaminated air. “Some small children can be exposed if they eat paint chips containing lead or if the toys and other objects they put in their mouth have been exposed to lead dust or dirt.”

Lead is less likely to enter your body through the skin, and this does not happen very often, the EPA adds.

According to the Ecology Center (www.leadfreewheels.org), an estimated 70,000 tons of lead is annually used in the manufacture of wheel weights worldwide. A typical vehicle contains from 200 to 250 grams (roughly seven to nine ounces) of lead in wheel weights.

“An average vehicle contains 10 wheel weights,” says the organization. “Although some effort is made to collect and recycle these weights at the end of a vehicle’s life, most of them are overlooked and often end up in the environment or as contaminants in the metal recycling process.”

The Responsible Purchasing Network (www.responsiblepurchasing.org) estimates that around 2,000 tons of lead wheel weights fall from vehicle wheels onto United States roadways every year. It has published the “Responsible Purchasing Guide: Light-duty Tires and Wheel Weights,” which emphasizes the use of lead-free wheel weights.

The Pacific Northwest Pollution Prevention Resource Center (www.pprc.org) researched viable alternatives to lead in a 2007 study. It classified wheel weight materials such as PVC plastic and zinc as sources for “environmental concern,” and chose steel as the most “environmentally preferable option.”

About the Author

Bob Ulrich

Bob Ulrich was named Modern Tire Dealer editor in August 2000 and retired in January 2020. He joined the magazine in 1985 as assistant editor, and had been responsible for gathering statistical information for MTD's "Facts Issue" since 1993. He won numerous awards for editorial and feature writing, including five gold medals from the International Automotive Media Association. Bob earned a B.A. in English literature from Ohio Northern University and has a law degree from the University of Akron.