Embracing effective methods for educating employees

Looking back on my 30 years in the tire business as a trainee and trainer, there are an infinite number of things that I would have done differently. As a young technician working for my dad, I took far too many chances and exercised far too little caution when handling inflated tires. I got lucky more than once. And when I became his unofficial trainer, I did little more than stop a few techs from hurting themselves. Barely.

From a training perspective, the first 14 years of my career were an accurate reflection of the state of the truck tire service industry up to the early 1990s.

For most commercial tire dealers back then, technician training was conducted on the job, a training method known as “on-the-job training,” or OJT. I’ve also heard it referred to as “old Joe training” because it usually involved an older and more experienced tech taking the new guy under his wing for a few weeks to watch and learn how to do it.

Once old Joe said you were OK, you were trained and it was time to go to work.

If you do an Internet search of on-the-job training today, you’ll find that it has become a proven method for educating employees. Wiki answers defines it as follows; “The best job training is ‘on-the-job training’ or OJT. OJT is best because this allows you to experience actually doing the job to see if you like it.” Well pass the guitar and the fresh organic wheat grass.

While most of the world can enjoy that break-in period where you get to “see if you like it,” the lives of truck tire technicians are more or less on the line the first time they handle or service an inflated tire.

Improperly serviced or inflated assemblies have resulted in far too many serious injuries and deaths over the years for someone to “see if they like it.”

If a new hire doesn’t understand the hazards going in, they may never get a chance to decide if it is the career for them.

Old Joe vs. OSHA

A recent look at the Occupational Safety and Health Administration (OSHA) fatalities proves my point. In the last two years, five out of 10 fatalities caused by an inflated tire occurred at trucking companies while the other half can be contributed to a tire dealer.

Statistically, that number should be a lot lower because the majority of truck tires that are serviced are outsourced to commercial tire dealers.

Since I saw the light back in 1996, I’m proud to say that training in the commercial tire service industry has improved considerably.

But my experience as an industry training developer and provider tells me that the transportation sector as a whole continues to embrace the old Joe method and I believe it’s costing people their lives.

While I don’t have the specific details regarding the recent accidents in trucking, here is what OSHA said about each fatality:

• Worker rotating truck tires was killed when one of the rings holding the tire in place struck him in the head.

• Worker struck by pieces of a large tire that exploded while adding air to it.

• Worker was struck and killed by parts of rim that exploded while tire was being changed.

• Worker was killed when the tractor tire he was inflating exploded.

• One worker was killed, another injured after the tire they were removing blew off the axle.

The problem with OJT as the only source of training for truck tire and wheel service back in the day was that it created a system where generations of bad habits got passed down from one Joe to the next.

It worked like this. The first old Joe showed the new guy all of his bad habits. Then the new guy became the next old Joe and passed down the original old Joe’s bad habits in addition to a few more tricks he learned himself over the years. And if one of those new guys had prior experience, he tacked on another generation or two of bad habits that he learned from someone else. Each old Joe perpetuated generations of bad habits and started an endless pattern that was inconsistent and dangerous.

[PAGEBREAK]

How people learn

As it stands today, most technicians in the commercial tire service industry have been formally trained to deflate multi-piece tire and rim assemblies before removing them from a vehicle because damaged or mismatched components can result in a separation. They are also taught to use OSHA-compliant tire inflation devices and stay out of the trajectory during the inflation process. I know this because I’ve been writing and developing training programs for the last 16 years. And while it’s unfair to speculate whether any or all of these accidents in trucking were preventable, at first glance it appears that proper training could have saved at least one family from the pain of losing a loved one.

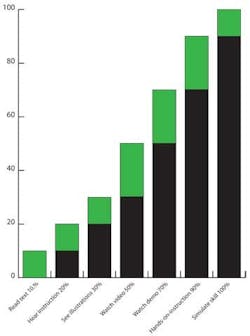

People make careers out of studying how people learn so training developers like myself can formulate the best plan for teaching them a particular skill. Each model is a little different, so I’ve combined a few of them to put together a chart (Chart A) that I think does a good job of demonstrating how people learn versus how much they remember.

If you hand a textbook to the average person, they can only be expected to remember about 10% of the basic information. If they read it and then someone explains it, the retention rate jumps to 20%. Add some pictures and you’re up to 30%, and if there’s video, the average person should remember about 50% of the main points. Throw in a live demonstration and some hands-on instruction with the base knowledge in place, and the retention rate jumps to 90%. Finally, if the student then simulates the skill, they should be able to remember 100% of the most important information.

If this model is applied to the typical OJT method in the tire business, then you start with the 10% for hearing the words because old Joe has to explain it to some degree.

Of course, if the words are wrong, then this model will just ensure that everyone will do the same thing the wrong way, but we’ll get to that later. Then we’ll add another 20% for watching the demonstration. However, the hands-on teaching doesn’t really count because old Joe may not be able to explain the “why” behind each step in the process (and they could still be wrong). But I’ll toss in another 10% for simulation because old Joe still has to watch the employee do it before signing off. If you do the math with this model, traditional OJT results in a retention rate of just 40% and some or most of it could be wrong (Chart B).

Why training is necessary

Once you understand how people learn and retain information, it’s equally important to think about why training is necessary in the first place. Safety is definitely a factor as evidenced by the number of people who are fatally injured each year. Liability is always a concern because a poorly or improperly trained employee makes it easy for the jury to assign blame after an accident. And in the case of truck tires and other large tires, it’s an OSHA requirement so it’s basically the law. But my golden rule of training has always been, “To change behavior in a positive manner.” That’s the essence of educating employees.

While I’ve mainly applied this theory to tire and wheel service, behavior can always be changed in a positive manner regardless of the job. Whether you are trying to get employees to do something better or safer, the ultimate goal is usually to get them to do it differently so it improves or do it the same way if it’s working.

When the model in Chart A is applied to the Tire Industry Association (TIA) Commercial Tire Service (CTS) training and certification, it’s easy to see why this program has achieved the goal of making positive changes in behavior.

TIA training and certification is based on a process manual with an accompanying video that includes specific step-by-step procedures for servicing tires and wheels.

While 20 old Joes could teach 20 different ways, the first half of this structured training program will always be the same for every trainee. It is also compliant with federal regulations and consistent with manufacturer guidelines as well as industry standards.

The videos are broken up into short modules so the students can grasp one concept at a time. Each one builds up to the next and by the time they are finished, they have a much clearer picture of the basic safety procedures for servicing tires. Companies can have 30 or 300 locations and still ensure that everyone is taught the same way.

And when everyone starts following the same rules, behavior is ultimately changed in a positive manner.

For example, torque wrenches in the commercial tire business were virtually non-existent in the 20th century and restraining devices, or safety cages, were rarely used.

However, in the last decade both have become commonplace among the major truck tire and wheel service providers. Most wheels in the commercial tire service industry are now installed with a torque wrench using the recommended guidelines for ensuring sufficient clamping force.

In less than 10 years, the industry has come a long way from the “good-and-tight” days of impact wrenches. And the increased use of restraining devices both in the shop and on the road during the inflation process has undoubtedly prevented countless technicians from being injured.

What’s even more impressive about commercial tire dealers is that most employees are not allowed to even touch a tire until they complete a TIA training program.

[PAGEBREAK]

Old Joe training still being used

Behavior has definitely been changed in a positive manner when it comes to the training of professional commercial tire service technicians and the procedures they follow. However, I believe that the trucking industry is still using old Joe and the OSHA data shows it’s not working very well.

Watching a demonstration contributes another 20% toward total retention, which is why it’s important to note that all TIA certification classes are taught by certified instructors who have completed in-depth hands-on training from a TIA staff instructor.

That means the instruction they provide and the skills they demonstrate are more likely to be correct. Many of these certified instructors also are responsible for new employee training, so the consistency in the message and the accompanying demonstration are second-to-none year after year.

Teaching the skill adds 20% so it is equally important as the demonstration. A big part of TIA training and certification is the hands-on portion. This is an opportunity for the student to attempt to duplicate the skills that were demonstrated. Again, the TIA instructor is able to provide positive feedback on positioning, leverage and trajectory during each step of the process. Old Joe says don’t sit on the tire when you inflate it.

Finally, the student must simulate the skill on their own before achieving complete retention of the basic concepts. In order to receive a certification or certificate from TIA, a skills demonstration form must be signed by a supervisor or certified instructor.

This provides documented proof that the student actually performed the specific skills with some degree of proficiency. It also gives the instructor a final chance to provide individual feedback, which helps students improve.

Positively changing behavior

The purpose of this article was not to promote TIA training and certification. I’m just using it as an example of how one educational approach fits into the model described by Chart A and ultimately changes behavior in a positive manner. If all of those same learning components are present in other training programs, then they can be just as effective as if they contain the same level of information and consistency with established industry practices and regulations.

Behavior in the commercial truck tire service industry has been changed, but the trucking business appears to follow many of the same old unsafe procedures and the results are tragic.

It’s starting to change in passenger and light truck tires because more and more retailers are recognizing that OJT and introductory videos are becoming less effective, especially with TPMS.

We’ve heard it during every Certified Automotive Tire Service (ATS) Instructor class for the past 10 years. Most of the students had no idea this level of training was available and they end up changing behavior in a positive manner when they return to their respective shops. Based on what we hear in our training classes, there is still a lot of misinformation out there just like there was in the commercial tire service industry years ago.

And while I’ve intentionally avoided discussing liability, retailers must understand that the best protection in the event of an accident is a properly trained technician. The major commercial tire dealers recognized that years ago and now it’s rare when an employee is not qualified to service truck tires and wheels. It’s the cheapest insurance out there, yet I believe there are still thousands of poorly trained technicians in the passenger and light truck tire industry. TIA has been conducting a national tour of ATS Instructor classes and the feedback indicates there are still practices being followed that are incorrect and/or unsafe.

History has proven that behavior can be changed in a positive manner, but the retail industry as a whole must say goodbye to old Joe and embrace more effective methods for educating employees if they want to see improvement. ■

Kevin Rohlwing is senior vice president of training for the Tire Industry Association. For more information, he can be reached at [email protected].

About the Author

Bob Ulrich

Bob Ulrich was named Modern Tire Dealer editor in August 2000 and retired in January 2020. He joined the magazine in 1985 as assistant editor, and had been responsible for gathering statistical information for MTD's "Facts Issue" since 1993. He won numerous awards for editorial and feature writing, including five gold medals from the International Automotive Media Association. Bob earned a B.A. in English literature from Ohio Northern University and has a law degree from the University of Akron.