Rotary Lift: shops meet cycle time demands

According to a new study by Rotary Lift, repair shop owners are facing growing customer demand for faster service. Shops now must find ways to improve bay productivity in order to move more vehicles profitably through the shop.

Rotary anonymously surveyed 327 U.S. shop owners about the trend toward faster cycle times. Of those surveyed, 70% reported that average sales amount per shop ticket has increased over the last five years.

At the same time, 46% reported that the average number of shop tickets their shops handle has also gone up during that time.

The study also covers how shops are capitalizing on this increasing demand. Most of them (71%) are focusing on improving bay productivity and speed of service so they can handle more business.

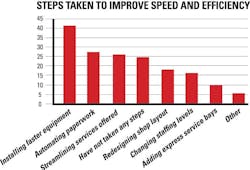

Shop owners have taken various steps to achieve these goals. Many have installed faster service equipment. Others have automated customer paperwork, streamlined their services, redesigned the shop layout or changed staffing levels. Profits have increased as a result of these steps for 77% of shop owners surveyed.

“For most shops, the one piece of equipment they rely on more than any other is the vehicle lift,” says John Rylee, Rotary Lift director of marketing. “By making the lift faster and easier to use, we can help technicians work more quickly, improving bay productivity and, as a result, shop profitability. That’s the value proposition of our new Shockwave system — it turns Rotary Lift two-post and inground lifts into the world’s fastest lifts, making them twice as fast as other lifts.”

For more information on the Shockwave, click here.