Special Envoy

SUBJECT VEHICLE: 2009 GMC Envoy.

SENSOR IN TIRE? Yes (in each tire and wheel assembly).

RESET PROCEDURE? Yes (whenever a new sensor has been installed, the vehicle’s tires have been rotated or the tire pressure monitoring system’s Endgate Module/Liftgate Module has been replaced).

SPECIAL TOOLS NEEDED? Yes (TPM Sensor Activation Tool J-46079).

The 2009 Envoy’s tire pressure monitoring system (TPMS) lets the driver view individual tire pressures and their locations while the vehicle is being driven.

The system contains several components: the Powertrain Control Module (PCM), the Body Control Module (BCM), the Instrument Panel Cluster (IPC), the Driver Information Center (DIC), and a Radio Frequency (RF) transmitter in each tire and wheel assembly. Models with a power sliding rear roof also come with an Endgate Module (EGM). All other models contain the Liftgate Module (LGM).

When the vehicle is stationary, the sensors go into stationary mode. Here they transmit data once every 60 minutes. As the vehicle begins moving and its speed increases, the sensors enter drive mode and transmit once every 60 seconds.

The EGM/LGM receives and translates the data contained in each sensor transmission, then sends the tire pressure information to the DIC. When the TPMS detects a significantly underinflated tire, a “CHECK PRESSURE MESSAGE” appears on the DIC and a low tire pressure indicator is displayed on the IPC.

How do you remove an old tire pressure sensor and replace it with a new one? Follow these steps:

1. Remove the tire and wheel assembly from the Envoy.

2. Demount the tire from the rim following the tire changer manufacturer’s specifications.

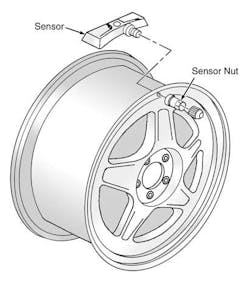

3. Remove the tire pressure sensor nut (see Figure 1).

4. Remove the sensor from the wheel hole.

5. Remove the sensor grommet from the wheel stem.

After removal, place the sensor’s cap and valve on a dry, clean surface. The cap is made of aluminum and the valve is nickel-plated. Do not substitute a cap or valve made of any other material.

[PAGEBREAK]

Now you’re ready to install the new sensor. Follow these steps:

1. Clean any dirt or debris from the grommet sealing areas. Install the grommet on the sensor valve stem.

2. Insert the sensor in the wheel hole with the air passage facing away from the wheel.

3. Install the sensor nut and position the sensor body parallel to the inside wheel surface while tightening the nut to 62 in.-lb.

4. Install the tire on the wheel following the tire changer manufacturers’ instructions.

5. Install the tire and wheel assembly on the Envoy.

Keep in mind that replacement sensors are shipped in OFF mode. In this mode, the sensor’s unique identification code cannot be learned into the EGM/LGM’s memory. The sensor must be taken out of OFF mode by spinning the tire/wheel assembly above 20 mph for at least 10 seconds in order to close the sensor’s internal roll switch.

Sensor relearn process

The sensor relearn process must be performed after every sensor replacement, tire rotation and/or EGM/LGM replacement.

Once the TPMS learn mode has been enabled, each unique sensor identification code can be learned into the EGM/LGM memory. When a sensor’s ID has been learned, the EGM/LGM sends a serial data message to the BCM, which sounds a horn chirp. This verifies that the sensor has transmitted its ID and the EGM/LGM has received and learned it.

The EGM/LGM must learn the sensor IDs in the proper order to determine the correct sensor location. The first learned ID is assigned to the left front location, the second to the right front, the third to the right rear and the fourth to the left rear.

The TPMS will cancel the learn mode if more than two minutes have passed and no sensors have been learned or if the system has been in learn mode for more than five minutes.

If the learn mode is canceled before any sensor has been learned, the EGM/LGM will remember all current sensor IDs and their locations. As soon as the first sensor ID code is learned, all of the other IDs are erased from the EGM/LGM’s memory.

[PAGEBREAK]

Before proceeding with the following steps, make sure no other sensor learn procedure is being performed at the same time or that tire pressure levels are not being adjusted on a TPMS-equipped vehicle in close proximity.

Also, you may use TPM Sensor Activation Tool (J-46079) in place of increasing or decreasing pressure levels to enable the sensor. To use this tool, place the activator antenna against the tire sidewall close to the wheel at the valve stem location, then press and release the ACTIVATE button.

If the TPM Sensor Activation Tool is used and the vehicle is having trouble entering relearn mode, check the tool’s batteries. When the internal battery is charged, the indicator is “full” or all dark.

When the battery is depleted, the indicator shows “empty” or all light. Here are the relearn steps:

1. Turn the ignition switch to the ON position with the engine off. Apply the parking brake.

2. Turn the headlight switch from OFF to parking lights four times within four seconds. A double horn chirp will sound and the low tire pressure indicator will start to flash. This indicates that learn mode has been enabled.

3. Starting with the left front tire, increase or decrease the pressure for eight to 10 seconds or until a horn chirp sounds.

4. After the chirp has sounded, proceed as in step three for the next three sensors in this order: right front, right rear and left rear. Do not deviate from this order.

5. After the final sensor has been learned, turn the ignition switch OFF.

6. Adjust all tire pressures to specification.

One final note: After performing the above procedure, always test drive the Envoy above 25 mph for at least two minutes before viewing the tire pressure readings on the DIC. ■

Information for this column comes from Mitchell 1’s ”Tire Pressure Monitoring Systems Guide” for domestic and import vehicles through 2009. Headquartered in Poway, Calif., Mitchell 1 has provided quality repair information solutions to the automotive industry for more than 80 years. For more information, visit www.mitchell1.com.