Special tools needed for the Audi Q7

SUBJECT VEHICLE: 2010 Audi Q7.

SPECIAL TOOLS NEEDED? Yes, a torque wrench (V.A.G. 1410), and socket (V.A.G. 1410/1).

If a wheel sensor of the tire pressure monitoring system (TPMS) on the 2010 Audi Q7 senses a significant loss of air pressure in one or more tires, the sensor(s) sends signals (values) to the tire pressure monitoring antenna. The antenna transfers the values to the tire pressure control module.

The control module then transfers the values to the driver information system in the instrument cluster. Then it displays a flat tire symbol and the text message “CHECK TIRE PRESSURE.” After a few seconds, the message is replaced by the regular display; press the “CHECK” button to show the message again. If tire pressure is significantly different in one or more tires, check the tire(s) for damage or foreign objects. Replace the tire(s) if necessary.

The low pressure warning light in the instrument cluster illuminates when:

• Tire pressure is 7 psi (48 kPa) lower than it should be;

• Wheel(s) are installed without a tire pressure sensor;

• Winter tires are installed;

• Incorrect pressure sensors are installed.

To remove an old sensor, follow these steps.

1. Remove tire and wheel assembly from the vehicle.

2. Demount the tire from the wheel following the tire changer manufacturer’s instructions while paying special attention to the following to avoid damaging the pressure sensor:

a. Press the tire off both rim edges on the opposite side to the metal valve.

b. Turn the wheel on the tire mounting equipment so that the valve/tire pressure sensor is opposite the mounting head. NOTE: To perform this procedure, a torque wrench (V.A.G. 1410) and socket (V.A.G. 1410/1) are required.

3. To remove the Beru System tire pressure sensors:

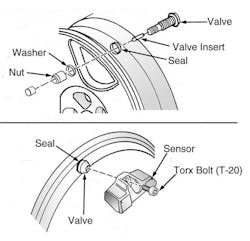

a. While holding the tire pressure sensor against the wheel rim, remove the torx fastener. See Figure. 2.

b. While counter-holding the metal valve body, remove union nut and metal valve. See Figure 3.

c. Remove and discard the valve insert from the valve stem.

To install a new sensor, follow these steps. NOTE: When reusing tire pressure sensors, inspect the connection between the sensor and the metal valve for damage. It is also necessary to replace the valve nut, nickel-plated valve insert, sealing ring, sealing washer and valve cap when reusing tire pressure sensors. See Figure 1.

1. To install Beru System tire pressure sensors:

a. Install the metal valve body, and while counter-holding the valve (for example, 2 mm twist drill or counter holding tool — see Figure 1), tighten the union nut to specification.

b. Press and hold the tire pressure sensor against the wheel rim and tighten the torx fastener to specification.

[PAGEBREAK]

2. Mount the tire on the wheel following the tire changer manufacturer’s instructions, paying special attention to the following to avoid damaging the tire pressure sensor:

a. Make sure that the tire does not contact the tire pressure sensor while mounting the tire.

b. Turn the wheel on the tire mounting equipment so that the valve/tire pressure sensor is opposite the mounting head.

3. Install the tire and wheel assembly to the vehicle.

4. Adjust the inflation pressures of all tires (including spare tire), and balance the tires. Store the new tire pressures in the system. NOTE: Whenever tire pressure is adjusted, the adjusted pressure has to be stored again. If a tire was changed or relocated, the new or relocated tire(s) must be initialized. Check and correct the tire inflation pressures of the wheels on the vehicle as provided on the tire pressure label. After properly inflating the tires, current pressures have to be stored in the monitoring system. The system then implements an automatic adaptation process.

When a tire pressure monitoring system malfunction occurs, it will be indicated when the ignition is turned ON and the yellow malfunction lamp in the instrument cluster will flash for one minute and then stay ON. The yellow malfunction lamp cannot be switched OFF by pressing the multimedia system control button on the center console. This could be caused by the following:

[PAGEBREAK]

• If this symbol is displayed at the end of a learning phase, it means that the system cannot recognize which wheels are mounted on the vehicle. This may be because one or more wheels were mounted lacking a wheel sensor.

• A wheel sensor or other component may have failed.

• The system recognizes more than four wheels are present on the vehicle (i.e., when additional winter tires are being transported on the vehicle and are transmitting data).

• A wheel was changed, and the new tire was not initialized.

• If the vehicle is being operated with snow chains, system function can be affected by the shielding effect of the chains.

• The system is not available due to a malfunction.

• Other transmitting devices with the same frequency are emitting an electromagnetic field which can cause temporary interference in the system.

To store tire inflation pressures, follow these steps .

1. Adjust air pressure in all tires to specifications (as provided on the vehicle’s tire pressure label).

2. Turn the ignition on.

3. Select “CAR,” “SYSTEMS,” and “TIRE PRESSURES MONITORING.”

4. Press the multimedia control button on the center console when in the Tire Pressure Monitoring menu.

5. The new pressures will be saved whtn the vehicle is driven.

Information for this column comes from Mitchell 1’s ”Tire Pressure Monitoring Systems Guide” for domestic and import vehicles through 2010. Headquartered in Poway, Calif., Mitchell 1 has provided quality repair information solutions to the automotive industry for more than 80 years. For more information, visit www.mitchell1.com.