AG Tire Talk: Variability in Air Pressure Rules

QUESTIONS: Why are ag tire air pressure requirements different for free rolling, low torque and high torque applications? Why are very high-flexion (VF) single tires allowed minimum inflation of 12 psi, whereas duals/triples are allowed minimum inflation of six psi with some tire manufacturers? And what is the reason for weight carrying capacity reduction of 12% for duals and 18% for triples?

DAVE PAULK, manager, field technical services, BKT USA Inc.: There are differences between bias tire and radial tires when running in a free rolling application versus a drive wheel application (high or low torque). In most cases, radial tires are used in mixed service (drive wheel and free rolling) without a noticeable difference in air pressures and load carrying capacities.

With radial tires, the load capacities don’t change with the application change.

This is not the case with bias tires because of the construction of the tire and the effects of load, speed and torque when used in a drive wheel (DW) application. When used in a free rolling (FR) application, the tire is pulled by a tractor on a wagon or cart. It is pulled across the ground and has no slippage and no torque applied to the tire. Without the effects of torque, the tire can carry more load.

When used in a DW application, the engine, bearings and gears all create a bit of friction. Some slippage from torque occurs from the power of the machine to the tire and to the ground. Used as a drive tire, this limits the amount of weight the tire can carry. Torque is the applied force around an axis — in this case, the axle — and produced by an engine. The amount of torque generated is predicated by gear ratios and the RPMs used to generate power. When you think of a torque wrench, the person is generating power.

The longer the handle, the more force that can be applied. This is the same concept as torque on bias tires.VF technology tires are becoming more prominent and more widely used because the weight carrying capacity is greater than a standard tire and they can be run at lower air pressures to minimize compaction. Air pressure carries weight, so the right amount of air pressure must be used to minimize damage to the tires.

Lower air pressure can be run in duals and triples versus running singles. When using duals/triples, the tires provide more floatation and share the load of the tractor/implements. When using singles, there is only one tire per side to spread the weight of the tractor. When running duals and triples, air pressures can be dropped below the required pressures.

Duals/triples can carry the same weight at lower air pressures versus a single tire.

When using duals/triples, the weight carrying capacity of the tire is diminished by 12% on duals and 18% on triples.

Although low air pressures can be used in this application, thought must be given to ensure that enough air pressure is being used to carry the weight based on these percentages. When using duals and triples, the deflection of the tires when weighted must be considered. Minimum spacing must be maintained between tires so that they clean out and don’t pick up sticks, rocks and other trash and damage the sidewalls.

Weight carrying capacities and recommended air inflation for the loads being carried can be found in load and inflation charts on the manufacturers’ websites or in data books. If only the load and inflation for singles are given in the load chart, multiply the carrying capacity by 0.88 for duals and 0.82 for triples at the corresponding air pressure. This will give the carrying capacity in dual/triple applications.

GREG GILLAND, vice president global agriculture, Maxam Tire North America Inc.: Tires face different forces that act upon the structure of the tire to carry a load from point A to point B. Every ag tire faces three forces to help move your tractor forward or in reverse:

• X force drives the tractor forward or backward.

• Y force stabilizes the tire from side-toside movement.

• Z force supports the load or weight being carried.

Tires must be able to transmit the engine torque or power, which overcomes the rolling resistance, also known as tire slip, providing the forward or rear motion to move the machinery. In the case of agricultural radial tires, 80% of the weight is carried by the compressed air in the tire chamber, which is adjusted based on three given working conditions: axle load or weight, speed and the desired tire contact patch or footprint.

Each of the above conditions will dictate the capability or limitations of the tire to achieve its purpose of moving a given load from point to point.

The ag industry has termed three different air pressure possibilities that a tire may face when operating in dynamic work conditions:

Free-rolling applications are present when an ag tire is on towed wheel position where the tires are only subjected to axle load applied and the pulling force of a powered tractor or unit. The only limitation is the weight on the tires for a given maximum speed.

Low torque applications are when an ag tire is on a powered wheel position with both load and lower torque applied due to reduced power applications to pull an implement across a field for a given work application such as planting.

High torque applications are when an ag tire is on a powered wheel position with very high torque or power applied to pull an implement or load at very high speeds, mostly due to transportation requirements or movement from one place to another.

The working requirements for the tire will be based on the vehicle purpose or tire configuration, closely followed by the work applications to determine which air pressure conditions to consider.

In all instances, the criteria to determine what air pressure is required will be determined by:

• Machine: MFWD tractor, 4WD tractor, harvester, floater, sprayer, grain tank,or implement, etc.;

• Size and wheel position: Front axle tire, rear axle tire, trailer axle position;

• Configuration: Single, dual or triple;

• Maximum axle load: Weight per tire;

• Cyclic load: Work conditions fully laden and then fully unladen, and;

• Speed: What is the highest speed to complete work requirements?

In an ideal world, all agricultural platforms would be equipped with vehicle-mounted central inflation systems.

These systems would allow tire air pressure adjustments at the touch of a button, switching between lower air pressure for low torque field applications and higher pressure for faster high-torque operations when moving from field to field.

As a rule, when operating at lower torque (lower speed) in the field, an ag tire can use lower air pressures to carry significant loads, allowing the sidewall to deflect as needed and increase the tire tread contact area, reducing soil compaction while increasing the tread footprint delivering greater traction.

Conversely, when faced with the need to move a machine or platform from one field to another, air pressure must be increased as the higher transport speed will require more air pressure to allow the load carrying capacity to adjust to the higher heat generated by the increased velocity. If the platform in question has a central inflation on-board system, this air pressure change can be applied immediately, allowing the optimal air pressure to be added to the tires to achieve the desired load carrying capability for a given speed.

DAVID GRADEN, global account manager, agriculture, Michelin North America Inc.: There are many variables tire manufacturers consider when making tire pressure recommendations, all taking into consideration tire application.

Free-rolling tire — lower psi: Free rolling tires only need to be able to carry the weight from above, while at the same time handling the undulating ground beneath it as it rolls, as well as the movement of rubber and heat buildup, depending upon the speed. As free- rolling tire positions have no torque, air pressures can be reduced when compared to drive tires.

Drive tires — higher psi: Pressures for drive tires under torque take these same variables into consideration, while also considering the linear forces put upon them. Consequently, higher air pressures are required for drive tires versus free rolling position tires.

Decreasing torque — less psi required: Air pressure can also be reduced in low torque applications versus high torque applications.

For example, if a tire is required to carry 6,500 pounds, six psi can be used in a six mph low torque “planter application” and seven psi must be used in a six mph high torque “plowing application.”

When recommending air pressures for duals or triples, we calculate in a 12% or 18% reduction in weight capacity as a standard safety and performance adjustment. The easiest way to explain this is due to the weight shift of a machine as it moves through a field.

Each tire is mounted to the tire before it. Since there is no pivoting joint between each tire, as they extend out further, weight shift will compound and grow, thus the potential for overloading one tire becomes a concern. Tire manufacturers take this into account when developing their air pressure tables.

CHRIS NEIDERT, ag marketing, training and development manager for Trelleborg and Mitas Tires — North America, Yokohama TWS: Free-rolling tires are not trying to apply any torque to the ground. Their main mission is to carry the load.

In a drive tire application, the tire is trying to grab the soil and the sidewall flexes. Think of what happens in a tractor pull. When the tractor engine RPMs start increasing and the engine starts to apply torque to the drive train and then to the tires, the sidewall flexes. That flexing sidewall needs higher air pressure to help the tire keep its shape. Increased pressure reduces the rim slip during extreme torque applications.

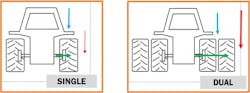

In the diagram on the first page of this article, the top picture shows the load/force situation with a single tire application. The axle is the green arrow and the center of gravity of the right half of the axle is indicated by the blue arrow. There is a load/force being exerted on the axle and the air pressure of the tire is carrying that load, depicted by the red arrow.

When you change to a dual configuration, things start to happen. Many would think because you have more tires on the axle, you can reduce the air pressure. This is true, but we now need to consider the center of gravity has shifted away from the tractor compared to the single tire fitment. Considering that, this is putting more strain on the axle, depicted by the larger/bolder red arrow in the lower image. Even though the axle weight has not changed, the additional strain — because the center of gravity has changed — is not good for the axle. Increasing the tire air pressure will help, acting to support that changed center of gravity. The same will be true for triples, shifting the center of gravity even more will require the need for even more increased pressure to support this change.

Trelleborg and Mitas never advocate going below 12 psi on any application or configuration, for several reasons. Many air pressure gauges being used may not have enough increments to show that preciseness of the air pressure reading.

And some people tend to ignore checking air pressure. Ignoring pressure when you have only six psi in the tire does not leave a lot of room for the normal fluctuation that occurs. When was the last time you checked your passenger vehicle tire air pressure?

About the Author

AG Tire Talk

Modern Tire Dealer has partnered with AG Tire Talk to provide answers to insightful questions that farm tire dealers have about farm tire technology. This is the latest installment in our ongoing series, which is designed to help farm tire dealers better connect with their customers. A trending question, followed by answers, appears in the Commercial Tire Dealer section of MTD every other month. For complete answers, go to www.agtiretalk.com.