QUESTIONS: When a producer is buying sprayer flotation tire assemblies, what should they look for to ensure maximum footprint and the least soil compaction? Which wheel width is best and when should a farmer choose R-1, R-1W or a hybrid tread design?

NICK PHILLIPPI, product manager/technical support, North America, Ascenso Tires North America: Self-propelled sprayers have long been a hot topic in the tire industry. They have gotten faster and heavier and are more in use than ever in today’s farming practices. The original setup was narrow tires, but manufacturers had some difficulty getting acceptable performance from these tires.

Now we have wider flotation tire options available. The sprayer tire position has long been considered a benchmark for manufacturers to prove their merit in the high-tier level.

Sprayers have now moved from 600- to 1,000- to 1,200-gallon capacities with speeds exceeding 30 mph, with both of these items challenging tire performance. These units do more roading than any other farm field vehicle by percentage and the need for both hard surface wear and the ever-important safe handling are priority.

Over time, there was a move to go to wide flotation for spring and fall burn down and then switch back to narrows for the growing season row use.

The 380/90R46 and 650/65R38 were long the top and almost exclusive fitments and that has now moved to a variety of sizes — in the narrows into 50- and 54-inch rims and flotations with 42- and 46-inch rims. At the same time, more and more hybrid treads have been developed with a focus on this specific application.

The reality is the sprayer is rarely in mud conditions and the typical R-1 tread may simply not be the best choice.

In cases where the R-1 is doing the job, then there is really no reason to make the change, but in many cases there is a real opportunity to move to hybrid treads to gain in road wear, fuel savings and handling.

The hybrid, especially those with steel belts, will deliver a much more consistent pattern for weight distribution, will roll more freely for better fuel efficiency and will wear more evenly on hard surfaces while maintaining excellent traction in dry and loose soil conditions. R-1W, in most cases, would probably not be the best choice, unless the need has a traction priority and the roading is minimal.

DAVE PAULK, manager, field technical services, BKT USA Inc.: Typical tire sizes for sprayers are VF380/90R46 and the VF380/105R50. In many cases, users will change out the sizes mentioned above for wider tires in the spring, before planting, when spraying for weeds and/or for pre-emergence weeds or fertilizer spreading. This will give them a wider footprint to minimize soil compaction before planting. The wider tires provide better flotation in a wet spring.

Using cyclic field operation (CFO) tires on sprayers is commonplace, but this application is almost like CFO in reverse. CFO tires are for combines and grain carts that have cyclic loads during the combining cycle. They start empty and get heavier through the cycle. They empty and start the cycle all over again.

Sprayers start loaded and heavy. They reduce weight through their cycle. CFO gives load bonuses for heavy loads at field speed without changing air pressures in cyclic operations, generally zero to 10 mph. With all tires, the load capabilities go up as the speed comes down.

When choosing wider tires, the correct size rims must be used to ensure that the tire fits properly and gives the right amount of deflection for traction and for footprint.

The recommended rim for the tire should be used. When looking at charts, there are often alternate rim sizes, as well.

The alternate rim sizes will work, but the recommended rim size is the best to use if possible. With your help, the user must decide which tire is best for them and if it will fit their sprayer.

Generally, the wider the tire, the better, but sometimes the wider tire may not carry the heavy load and be rated for the speed. The less air pressure they can use to carry the load and the bigger footprint, the better to minimize soil compaction.

GREG GILLAND, vice president, global agriculture, Maxam Tire North America Inc.: Over the last 20 years, we have seen technological advancements drive solutions into the ag market that were considered impossible to resolve due to engineering or product limitations at that time. Specifically for self-propelled sprayer platforms, we have seen a significant improvement to tire technology which has allowed:

- The reduction of air pressures to reduce soil compaction, improving crop yields;

- The elimination of reinforced wheels reducing assembly weights; and

- The ability to increase tire speeds or heat resistance due to improved rubber compounding.

All three of these advancements have fundamentally changed sprayer designs, engineering and how they are marketed to both farmers and custom applicators or co-ops.

Radial ag very high-flexion (VF) technology has allowed sprayer tires to decrease air pressures by 40% while increasing roading speeds from plus-25 mph to plus-36 mph using “D” rubber compounds.

This allowed air pressures to decrease from 100 psi down to 60 psi while not impacting the load carrying capacity of the sprayer and transitioning back to standard rims, as opposed to reinforced rims for the air pressures needed previously. The resulting reduction in ground compaction impact was evident and obvious to all farming operations which improved crop yields and profits.

This single VF technology advancement on tire load and speed capability (heat generation) allowed the OEMs to achieve their objectives to evolve self-propelled sprayer chassis from plus-1,000 gallons to plus-2,000-gallon platforms. It also allowed for improved productivity through greater capacity tanks coupled with larger booms up to 132 feet or 40 meters. Regardless of these advancements, what remains consistent in the crop application business is that market needs dictate how farmers or growers will choose sprayer solutions to meet their profit goals.

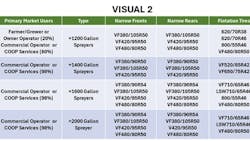

On the previous page, there is a summary table reviewing various OEM current VF tire options for narrows or flotation by tank size. As a rule, most of the sprayers below 1,000 gallons tend to be owned and operated by farmers or growers as part of their farms.

DAVID GRADEN, global account manager, agriculture, Michelin North America Inc.: Choosing to invest in sprayer flotation tires is a big decision. First, you really need to understand what a flotation tire offers your operation and what you want to gain from it.

Typically, producers tend to fit their sprayers with flotation tires because they want to reduce their soil compaction, improve flotation and overall efficiency in less-than-ideal spring soil conditions.

Buyer beware, though. Flotation tires are not all the same!

Let’s take a look at standard radial tires versus VF tires. You can achieve a wider footprint with both options, but the VF option provides a much longer footprint on the ground.

The VF footprint maximizes both flotation and traction, while carrying up to 40% more load than a standard radial tire, or running down to minus-40% air pressure compared to a standard tire of the same size.

If you choose a VF tire with CFO designation, you also gain a much wider range of recommended air pressures at lower speeds, instead of being limited to the standard 40 mph air pressures, like other VF sprayer tires.

Finally, when you couple the VF CFO flotation sprayer tires with a ... central tire inflation system (CTIS), you can really maximize your flotation, traction and overall efficiency at any speed with the simple push of a button.

Of course, before setting any air pressure levels for customers’ tires, you’ll need to know the loaded weight and speeds at which they will operate their machines.

JAMES CROUCH, Alliance’s national segment manager, agriculture, Yokohama Off-Highway Tires America Inc.: When you think of it, today’s sprayer has more in common — from a tire demand perspective — with a farm pickup than with a tractor. It’s a high-performance road vehicle.

In fact, most custom applicators spend as much time on the road as they do in the field and many farmers who invest in their own sprayers are covering fields in a wide radius that requires a lot of roading.

Tires are the secret weapon behind sprayers’ ability to carry more, run faster and operate with the sub-inch accuracy that befits the outstanding guidance systems inside the cab.

To make the most of a sprayer, farmers and custom applicators must be able to run as much as possible, including in imperfect conditions when machines are more likely to get stuck and soils are prone to more compaction.

Since sprayers split their time between the road, where speed demands higher inflation pressures, and the field, where improving traction and reducing soil compaction are paramount, investing in a CTIS can be extremely worthwhile. Cutting roading time, improving field performance, and increasing the service life of the tire can speed the payback of an investment in CTIS dramatically.

Another less-recognized advance is the development of hybrid tread patterns. Instead of old-fashioned tractor lugs — the same pattern that’s been used for more than 100 years — modern hybrid treads place industrial-style tread blocks in patterns that reinforce the centerline while curving towards the shoulders for traction.

The result is a tire that is stable and long-lasting on gravel and pavement, while it also delivers outstanding traction in the field on flat ground and side-hills. That straight-line and lateral traction keeps the sprayer right on target, enhancing the capabilities of GPS-driven equipment.

The bottom line is to treat your sprayer like the high-tech, high-performance road vehicle it is. Equip it with tires and wheels that will help it perform its best.

CHRIS NEIDERT, ag marketing, training and development manager for Trelleborg and Mitas Tires — North America, Yokohama TWS: First of all, let’s use a straight definition of flotation: The tendency of an object to float on the surface. Sinking is just the opposite process of flotation which means the tendency of an object to go deep down to the lower levels of the surface. Using flotation tires in your sprayer operation is a logical choice when no crop is established that could be damaged when driving over it.

Using a wider tire that will float on the soil will be very beneficial when the ground is soft during the early spring or the late fall. Not only will the flotation tires reduce compaction, but they will also reduce the possibility of rutting that happens when the ground is soft.

The type of tread pattern that you choose for your flotation sprayer tire is very important — R-1, R-1W, or hybrid tread design. As far as a sprayer tire application, we always recommend a R1 tread design. Better suited for high-speed road use as they are rated for 40 mph (D) speed. Our sprayer tire design not only features R-1 lug height, but also more lugs than tractor tires.

This assures faster heat dissipation and longer tire life — more lugs for a smoother ride and enough traction for sprayer applications.

About the Author

AG Tire Talk

Modern Tire Dealer has partnered with AG Tire Talk to provide answers to insightful questions that farm tire dealers have about farm tire technology. This is the latest installment in our ongoing series, which is designed to help farm tire dealers better connect with their customers. A trending question, followed by answers, appears in the Commercial Tire Dealer section of MTD every other month. For complete answers, go to www.agtiretalk.com.