Crossfire service aims to please

SUBJECT VEHICLE: 2005-08 Chrysler Crossfire.

RELEARN PROCEDURE? Yes, directions follow.

SPECIAL TOOLS NEEDED? Yes, a Chrysler DRB-III scan tool; a Relearn Magnet (8821).

The tire pressure monitoring system (TPMS) on the 2005-08 Chrysler Group LLC Crossfire utilizes a warning light in the instrument cluster and transmitters that are located in the valve stem of each tire. The transmitters communicate the tire pressure condition to the Universal Garage Door Opener/tire pressure monitor (TPM) module, which is located in the headliner near the inside rearview mirror.

This module has a microprocessor controller that can monitor the transmissions from tire pressure sensors/transmitters any time the ignition switch is in the “on” position. If a tire has low air pressure, an indicator light on the instrument cluster is illuminated. The TPMS does not determine which tire has a low pressure condition.

The TPMS operates by monitoring a radio frequency transmission from the tire pressure sensor/transmitters located in each wheel (integrated with the valve stem). When a vehicle reaches a speed of 20 mph, centrifugal force created by the wheels rotating closes a roll switch inside each sensor, powering up the circuitry. To facilitate transmitting the radio signal to the module, the valve stem acts as the antenna for the tire pressure sensor/transmitter.

To remove a sensor, follow these steps.

1. Remove the tire and wheel assembly from the vehicle. Remove the balancing weights from the wheel. Remove the cap from the valve stem. Remove the core from the valve stem. Allow the tire to fully deflate. CAUTION: The tire pressure sensor must be removed from the wheel and dropped into the tire prior to breaking the bead and demounting the tire. Failure to do this will greatly increase the risk of damaging the sensor when servicing the tire.

2. Remove the nut mounting the valve stem of the tire pressure sensor to the wheel. Drop the sensor into the tire. CAUTION: When breaking the top and bottom bead of the tire off the wheel, care must be used so the bead breaking mechanism on the tire changer does not damage the wheel. This includes the surface of the wheel flange on the inside of the wheel.

3. Using the tire changer manufacturer’s procedure, first break down the upper bead of the tire. Then break down the bottom bead of the tire. CAUTION: When demounting the upper tire bead from the wheel, the proper procedure must be used. Not using the proper procedure will result in damage to the wheel and tire.

4. Demount the upper bead of the tire from the wheel. The upper bead must be fully demounted from the wheel to remove the tire pressure sensor from the inside of the tire. The bottom bead of the tire does not need to be removed from the wheel. Pull upward on the tire. Reach inside the tire and remove the tire pressure sensor.

To install a sensor, follow these steps. NOTE: When installing a tire pressure sensor, replace the sealing grommet at the valve stem base before installing the sensor in the wheel. Also, be sure that the surface of the wheel that the grommet seals against is clean and not damaged.

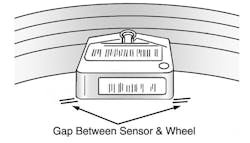

1. Wipe the area clean where the sensor sealing grommet contacts the wheel. Make sure the surface of the wheel is not damaged. NOTE: Once tightened, the gap between the sensor and the wheel must be even on both sides as shown in Figure 1. If the sensor rotates (clockwise), damage to the sensor can occur when mounting the tire. Tighten the nut to 35 in.-lbs. (4 N.m).

2. Install the tire pressure sensor on the wheel. Install the special sensor mounting nut. When tightening the tire pressure sensor nut, hold the sensor so that it does not rotate.

3. Mount the upper bead of the tire on the wheel. Inflate tire(s) to the proper specification. Install the original or an OEM replacement valve stem cap on the valve stem. Using a soap solution, check that no air leak is present where the valve stem mounts to the wheel.

4. Balance the tire/wheel assembly, using the correct procedure for using the wheel flange mount and stick-on wheel weights. Install the wheel and tire assembly on the vehicle.

5. Register the identification code for the new tire pressure sensor into the TPMS module.

6. To verify the TPMS functionality, connect the Chrysler DRB-III scan tool to the vehicle. Drive the vehicle at 25 mph for at least two minutes. While having an assistant monitor the scan tool, verify the operation of all four tire pressure sensors.

To retrain a sensor, follow these steps. WARNING: In the following procedure, Relearn Magnet (8821) is used. Death or serious injury can occur if magnetically sensitive devices are exposed to the retraining magnet used in the TPMS. Magnets can affect pacemakers.

NOTE: If a tire is changed (tire rotation), one or more tire pressure sensors fail, or if the TPMS module is replaced, the TPMS needs to relearn tire pressure sensor IDs. To perform this procedure, a Chrysler DRB-III scan tool and a Relearn Magnet (8821) must be used.

1. Connect the Chrysler DRB-III scan tool to the vehicle’s Data Link Connector located beneath the instrument panel, near the steering column.

2. Using the scan tool, access “Chassis System.”

3. Once in “Chassis System,” select “Miscellaneous Functions.”

4. Select “Train All Mode” from the menu selections. Select “Yes” to continue.

5. Place Relearn Magnet (8821) over the valve stem for the left front wheel.

6. Each sensor/transmitter will automatically sense the presence of the magnet and begin transmitting. When the tire pressure sensor on each wheel has been programmed, the DRB-III will automatically beep and direct you to the next wheel to be programmed. Move the magnet to each of the remaining wheels as directed by the scan tool.

7. Remove the magnet from the last tire to be programmed (left rear wheel).

8. Once “Training Completed” is displayed, exit the program function screen and use the following to verify TPMS functionality.

a. Verify TPMS module programming is complete by viewing the “Input/Output Display” selection of the DRB-III and confirming the tire pressure sensors are trained.

b. Verify TPMS module programming is complete by viewing the “Sensor Display” selection of the DRB-III and confirming the tire pressure sensor pressure readings are accurate.

Information for this column comes from Mitchell 1’s ”Tire Pressure Monitoring Systems Guide” for domestic and import vehicles through 2010. Headquartered in Poway, Calif., Mitchell 1 has provided quality repair information solutions to the automotive industry for more than 80 years. For more information, visit www.mitchell1.com.