GM escapade

SUBJECT VEHICLE: 2007-10 GM Escalade.

RELEARN PROCEDURE? Yes.

SPECIAL TOOLS NEEDED? Yes, a J-46079 Tire Pressure Monitor Diagnostic Tool.

The tire pressure monitoring system (TPMS) on 2007-2010 General Motors Escalades displays individual tire pressures and their locations on the Driver Information Center (DIC).

In addition to the DIC, the Escalade’s TPMS uses the Powertrain Control Module (PCM), the Body Control Module (BCM), an Instrument Panel Cluster (IPC), a Remote Control Door Lock Receiver (RCDLR) and a radio frequency (RF) transmitting pressure sensor in each wheel/tire assembly.

The RCDLR receives and translates the data contained in each sensor transmission, then sends the tire pressure and tire location data to the DIC for display. When the TPMS detects a significantly under-inflated tire pressure, a “Check Tire Pressure” message is displayed on the DIC and the low tire pressure indicator is displayed on the IPC.

Remove, identify, replace

To remove an old sensor, follow these steps. CAUTION: The tire should be demounted from the wheel using the tire changer manufacturer’s instructions. Use the following information to avoid damage during the demounting/mounting process.

NOTE: When the wheels have been rotated, or a tire pressure sensor or RCDLR has been replaced, retrain the tire pressure sensor.

There are currently two different kinds of sensors in use on 2007-10 Escalades. Identification of which sensor is in use can easily be made after the tire has been removed from the wheel by referring to Figure 1 and Figure 2.

1. Raise the vehicle on a suitable support. Remove the tire/wheel assembly from the vehicle.

2. Demount the tire from the wheel following the tire changer manufacturer’s instructions while paying special attention to the following steps to avoid damaging the tire pressure sensor.

a. Place the sensor’s cap and valve on a dry, clean surface after removal. The cap is aluminum and the valve is nickel-plated to prevent corrosion. DO NOT substitute a cap or valve made of any other material.

b. Position the bead braking fixture 90 degrees from the valve stem when separating the tire bead from the wheel.

c. Position the mounting/demounting head so the tire iron (or pry bar) can be inserted slightly clockwise of the sensor body when prying the tire bead up and over the mounting/demounting head.

d. Using the tire machine, rotate the tire/wheel assembly clockwise when transferring the tire bead to the outside of the wheel rim.

e. Repeat steps a-d for the inner bead.

[PAGEBREAK]

Clamp-in style sensor removal

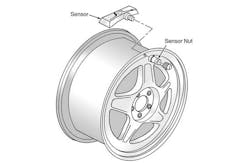

If the TPMS is the clamp-in style (Figure 1), follow these steps.

1. Remove the tire pressure sensor nut (see Figure 1).

2. Remove the sensor from the wheel hole.

3. Remove the sensor grommet from the valve stem.

4. Follow clamp-in sensor installation instructions below.

Snap-in style sensor removal

1. Remove the TORX screws (3) from the tire pressure sensor and pull it straight off the tire pressure valve stem. See Figure 2.

2. Remove the tire pressure valve stem.

3. Follow snap-in style sensor installation instructions.

Clamp-in sensor installation

1. Clean any dirt or debris from the grommet sealing areas. Install the grommet on the sensor valve stem.

2. Insert the sensor in the wheel hole with the air passage facing away from the wheel.

3. Install the sensor nut, and position the sensor body parallel to the inside wheel surface while tightening the nut to 62 in.-lbs. NOTE: A service replacement tire pressure sensor is shipped in the OFF mode. In this mode, the sensor’s unique identification code cannot be learned into the RCDLR’s memory. The sensor must be taken out of OFF mode by spinning the tire/wheel assembly above 20 mph for at least 10 seconds in order to close the sensor’s internal roll switch.

4. Before installing the tire on the wheel, note the following items to avoid tire pressure sensor damage upon tire mounting.

a. Position the mounting/demounting head 180 degrees from the valve stem.

b. Position the bead transition area 45 degrees counterclockwise of the valve stem.

c. Using a tire machine, rotate the tire/wheel assembly clockwise when transferring the tire bead to the inside of the wheel rim.

d. Repeat a-c for the outer bead.

5. Install the tire on the wheel. Install the tire/wheel assembly on the vehicle. Retrain the tire pressure sensor.

Snap-in style sensor installation

1. Assemble the tire pressure sensor to the valve stem and install the new TORX screw (3). See Figure 2.

2. Apply tire soap to the rubber portion of the valve stem.

3. Using a tire valve stem mounting tool, pull the valve stem through in a direction parallel to the valve hole on the rim. NOTE: Snap-fit sensors are shipped in the OFF mode. However, the sensor no longer needs to be spun to remove it from the OFF mode. The sensor will exit its OFF state when the tire is inflated. The tech can then program the vehicle as normal.

4. Before installing the tire on the wheel, note the following items to avoid sensor damage upon tire mounting.

a. Position the mounting/demounting head 180 degrees from the valve stem.

b. Position the bead transition area 45 degrees counterclockwise of the valve stem.

c. Using a tire machine, rotate the tire/wheel assembly clockwise when transferring the tire bead to the inside of the wheel rim.

d. Repeat a-c for the outer bead.

5. Install the tire on the wheel. Install the tire/wheel assembly on the vehicle. Retrain the sensor.

[PAGEBREAK]

Tire pressure sensor relearn

There are three ways to enable the learn mode: using a scan tool, using the keyless entry transmitters (if equipped) or using the DIC.

After the learn mode has been enabled, there are two different methods of activating the transmitters in the tires: utilizing the J-46079 Tire Pressure Monitor Diagnostic Tool at each tire; or increase/decrease the tire pressure for eight to 10 seconds in each tire. If a scan tool has been used to enable the learn mode, the J-46079 must be used to activate the transmitters.

IMPORTANT: If a particular sensor’s information is displayed on the special tool upon activation, but the horn does not chirp, it may be necessary to rotate the wheel valve stem to a different position due to the sensor signal being blocked by another component.

1. Using a scan tool, initiate the Learn Mode. A double horn chirp will sound indicating the Learn Mode has been enabled. The left-front turn signal will also be illuminated.

2. Starting with the left-front tire, activate the sensor by holding the antenna of the J-46079 aimed upward against the tire sidewall close to the wheel rim at the valve stem location. Press and release the Activate button and wait for a horn chirp. Once the horn chirp has sounded, the sensor information is learned and the turn signal in the next location to be learned will illuminate.

3. After the horn chirp has sounded and the left-front turn signal is illuminated, repeat step 2 for the remaining three sensors in the following order: a) right-front, b) right-rear, and c) left-rear.

4. When the left-rear sensor has been learned and a double horn chirp has sounded, the learn process is complete and the RCDLR exits the learn mode.

5. Turn the ignition OFF. Adjust tire pressures. ■

Information for this column comes from Mitchell 1’s ”Tire Pressure Monitoring Systems Guide” for domestic and import vehicles through 2010. Headquartered in Poway, Calif., Mitchell 1 has provided quality repair information solutions to the automotive industry for more than 80 years. See the company’s website at www.mitchell1.com. For more TPMS articles, see the “Articles” channel on www.moderntiredealer.com.