2010-2013 Chevrolet Equinox and GMC Terrain

SUBJECT VEHICLE: 2010-2013 Chevrolet Equinox and GMC Terrain.

RELEARN PROCEDURE? Yes. The TPMS sensor relearn procedure must be performed after every tire rotation, body control module replacement, or sensor replacement.

SPECIAL TOOLS NEEDED? Yes. TPMS special tool (EL-46079 or EL-50448).

The tire pressure monitor system (TPMS) of the 2010 – 2013 Chevrolet Equinox and GMC Terrain uses the instrument panel cluster (IPC), body control module (BCM), four radio frequency transmitting pressure sensors, and the serial data circuit to perform the TPMS relearn mode functions.

Once the relearn mode has been enabled, each of the sensors’ unique identification codes can be learned into the BCM memory. When a sensor ID has been learned, the BCM sounds a horn chirp indicating the sensor has transmitted its ID and the BCM has received and learned it. The BCM must learn the sensor IDs in the proper sequence to determine correct sensor location. The first learned ID is assigned to the left front location, the second to right front, the third to right rear and the fourth to left rear. The turn signals will individually illuminate indicating which location is to be learned in the proper sequence.

When the TPMS detects a significant loss or gain of tire pressure, the tire pressure monitor indicator icon is illuminated on the instrument cluster and if equipped, a check tire pressure type message is displayed on the driver information center (DIC). Both the indicator icon and driver information center message can be cleared by adjusting the tire pressures to the recommended pressures and driving the vehicle above 25 mph (40 km/h) for at least two minutes.

Sensor activation methods

TPMS special tool (EL-46079 or EL-50448): Each sensor has an internal low frequency coil. When the TPMS tool is used in activate mode, it produces a low frequency transmission that activates the sensor. The sensor responds to a low frequency activation by transmitting in learn mode. When the BCM receives a learn mode transmission while in TPMS learn mode, it will assign that sensor’s ID to the location on the vehicle relative to the order in which it was learned.

Pressure change

Each sensor takes a pressure measurement sample once every 30 seconds while in stationary mode. If the tire pressure increases or decreases by more than 8.3 kPa (1.2 psi) from the last pressure measurement, another measurement will occur immediately to verify the change in pressure. If a pressure change has indeed occurred, the sensor transmits in learn mode. When the BCM receives a learn mode transmission while in TPMS learn mode, it will assign that sensor’s ID to the location on the vehicle relative to the order in which it was learned.

The relearn mode will cancel if the ignition is cycled to OFF or if more than two minutes has elapsed for any sensor that has not been learned. If the relearn mode is canceled before the first sensor is learned, the original sensor IDs will be maintained. If the relearn mode is canceled after the first sensor is learned, the following will occur:

- All stored sensor IDs will be invalidated in the BCM memory.

- If equipped, the DIC will display dashes instead of tire pressures.

- DTC C0775 will be set.

Tire pressure monitor warning indicators

As stated before, the TPMS warns the driver when a significant loss or gain of tire pressure occurs in any of the four tires and allows the driver to display the individual tire pressures and their locations on the DIC.

When the TPMS detects a significant loss or gain of tire pressure, the tire pressure monitor indicator icon is illuminated on the instrument cluster.

NOTE: If power is disconnected from the BCM or if the vehicle battery is disconnected, each tire pressure monitor sensor ID is retained but all of the tire pressure information is lost. The DIC will display all dashes and the scan tool will indicate a default tire pressure value of 1,020 kPa (148 psi) for each tire. Driving the vehicle above 25 mph (40 km/h) for at least two minutes will activate the sensors causing the DIC to display the current tire pressures.

The BCM has the ability to detect malfunctions within the TPMS. In the event a DTC is set, the tire pressure monitor indicator icon on the instrument cluster will flash for one minute and then remain illuminated after the ignition is turned ON and the instrument cluster bulb check has been completed. Any malfunction detected will cause the driver information center to display a service tire monitor system type message.

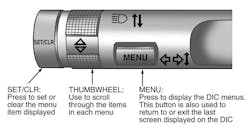

DIC: Press MENU on the turn signal lever until Vehicle Information Menu is displayed. Use to scroll through the following menu items:

- Unit

- Tire pressure

- Remaining oil life

The display will show the approximate pressures of all four tires. Tire pressure is displayed in either kilopascal (kPa) or pounds per square inch (psi).

Reset procedures

NOTE: The TPMS sensor relearn procedure must be performed after every tire rotation, BCM replacement, or sensor replacement.

NOTE: When the tire pressure monitor system detects a significant loss or gain of tire pressure, the tire pressure monitor indicator icon is illuminated on the instrument cluster and if equipped, a check tire pressure type message is displayed on the driver information center.

Both the indicator icon and driver information center message can be cleared by adjusting the tire pressures to the recommended pressures and driving the vehicle above 25 mph (40 km/h) for at least two minutes.

Tire pressure sensor relearn

NOTE: If using the TPMS tool to activate the sensors, any stray sensor signals will not affect the relearn procedure. In the event a particular sensor’s information is displayed on the special tool upon activation but the horn does not chirp, it may be necessary to rotate the wheel valve stem to a different position due to the sensor signal is being blocked by another component.

NOTE: If using the pressure increase/decrease sensor activation method, ensure that no other learn procedure is being performed simultaneously or that tire pressures are not being adjusted on another TPMS-equipped vehicle within close proximity. Stray signals from other TPMS-equipped vehicles just driving by can be inadvertently learned.

If any random horn chirps are heard from the vehicle while performing the learn procedure, most likely a stray sensor has been learned and the procedure will need to be canceled and repeated.

[PAGEBREAK]

Under these circumstances, performing the TPMS relearn procedure away from other vehicles would be highly recommended. In the event that a particular sensor activation does not cause the horn to chirp, it may be necessary to rotate the wheel valve stem to a different position due to the sensor signal is being blocked by another component.

1) Turn the ignition switch to the ACC position.

2) Activate the relearn mode using a scan tool or DIC buttons (refer to the owner’s manual). A double horn chirp sounds indicating the relearn mode has been enabled and the left front turn signal will also be illuminated.

3) Starting with the left front tire, activate the tire pressure sensor using one of the following methods:

- Increase/decrease the tire pressure for eight to 10 seconds then wait for a horn chirp. The horn chirp may occur before or up to 30 seconds after the eight to 10 second pressure increase/decrease time period has been reached. Once the horn chirp has sounded, the sensor information is learned and the turn signal in the next location to be learned will illuminate.

- Hold the antenna of the TPMS special tool (EL-46079 or EL-50448) aimed upward against the tire sidewall close to the rim at the valve stem location. Press and release the activate button. Ensure that the transmit indicator on the special tool indicates that the sensor activation signal is being transmitted. Wait for a horn chirp. If the horn does not chirp, repeat the sensor activation sequence with the tool. Once the horn chirp has sounded, the sensor information is learned and the turn signal in the next location to be learned will illuminate.

4) After the horn chirp has sounded and the right front turn signal is illuminated, repeat the procedure for the next three sensors in the following order: right front, right rear, left rear.

5) After the left rear sensor has been learned, a double horn chirp will sound, indicating all four sensor IDs have been learned. Turn the ignition switch to the OFF position. Adjust all tire pressures to specification.

Demounting/mounting procedures

CAUTION: The tire should be demounted from the wheel using the tire changer manufacturer’s instructions. Use the following information to avoid damage during the demounting/mounting procedures.

NOTE: If the vehicle’s tires are replaced with those not having a TPC spec number, the TPMS may give an inaccurate low pressure warning. Non-TPC spec tires may give a low pressure warning that is higher or lower than the proper warning level achieved by TPC spec numbered tires.

NOTE: If a tire pressure sensor or the RCDLR is replaced, or if the wheels have been rotated, the tire pressure sensor must be retrained. See reset procedures.

Tire pressure sensor

CAUTION: Do not inject any tire liquid or aerosol tire sealant into the tires, as this may cause a malfunction of the tire pressure sensors. If any tire sealant is noted upon tire demounting, replace the sensor. Also remove all residual liquid sealant from the inside of the tire and wheel surfaces.

Removal

1) Raise the vehicle on a suitable support. Remove the tire/wheel assembly from the vehicle.

2) Demount the tire from the wheel following the tire changer manufacturer’s instructions while paying special attention to the following to avoid damaging the tire pressure sensor:

Place the sensor’s cap and valve on a dry, clean surface after removal.

The cap is aluminum and the valve is nickel-plated to prevent corrosion. Do not substitute a cap or valve made of any other material.

- Position the bead breaking fixture 90 degrees from valve stem when separating the tire bead from the wheel.

- Position the mounting/demounting head so the tire iron can be inserted slightly clockwise of the sensor body when prying the tire bead up and over the mounting/demounting head.

- Using the tire machine, rotate tire/wheel assembly clockwise when transferring the tire bead to the outside of the wheel rim.

- Repeat items for the inner bead.

3) Remove the tire pressure sensor nut. (see Figure 2).

4) Remove the sensor from the wheel hole.

5) Remove the sensor grommet from the valve stem.

Installation

1) Clean any dirt or debris from the grommet sealing areas. Install the grommet on the sensor valve stem.

2) Insert the sensor in the wheel hole with the air passage facing away from the wheel.

3) Install the sensor nut, and position the sensor body parallel to the inside wheel surface while tightening the nut to 62 in.-lbs. (7 N.m).

4) Before installing the tire on the wheel, note the following items to avoid tire pressure sensor damage upon tire mounting:

- Position the mounting/demounting head 180 degrees from the valve stem. Position the bead transition area 45 degrees counterclockwise of valve stem.

- Using the tire machine, rotate the tire/wheel assembly clockwise when transferring the tire bead to the inside of the wheel rim.

- Repeat the items for the outer bead.

5) Install the tire on the wheel. Install the tire/wheel assembly on the vehicle. Retrain the tire pressure sensor. See reset procedures

NOTE: A service replacement tire pressure sensor is shipped in OFF mode. In this mode, the sensor’s unique identification code cannot be learned into the RCDLR’s memory.

The sensor must be taken out of OFF mode by spinning the tire/wheel assembly above 25 mph (40 km/h) for at least 10 seconds in order to close the sensor’s internal roll switch. ■

Information for this column comes from Mitchell 1’s “Tire Pressure Monitoring Systems Guide” for domestic and import vehicles. Headquartered in Poway, Calif., Mitchell 1 has provided quality repair information solutions to the automotive industry for more than 80 years.

For more information, visit website www.mitchell1.com.

For more TPMS articles, see:

2008-2013 Honda Accord and Crosstour TPMS