DESCRIPTION & OPERATION

The tire pressure monitoring system (TPMS) monitors the pressure and temperature inside the tire to warn the driver of changes in pressure which may influence the operation of the vehicle. The TPMS control module analyzes wireless information from sensors, and the system detects the pneumatic pressure of the tires and warns the driver if the pneumatic pressure drops below the standard level. Messages from the data are shown in the cluster through a warning lamp. The ECU performs an ERROR evaluation of the input and output signals, receives pressure data from the wheel sensors, determines the condition of the tires, and delivers the required warning messages to the driver via the CAN line or hardwire control line.

TPMS light ON/OFF conditions

Lamp ON: The lamp turns ON when the tire pressure decreases below the standard level.

Lamp OFF: The warning lamp turns OFF when the tire pressure exceeds the pressure required to turn off the lamp.

TPMS Fault Warning Lamp

Warning Conditions and Display: When the system detects a defect in the external operating environment (low battery voltage, abnormal vehicle speed, etc.), the warning lamp blinks for about one minute and then turns ON.

Lamp OFF: The warning lamp turns OFF when the DTC is resolved. The DTC is automatically resolved when the system does not receive any fault signals for 30 or more ignition cycles after it changes from the previous fault code.

CAUTION:

If this condition occurs while driving, you should check the cause of the fault even after the DTC is resolved. (Turn the ignition from OFF to ON. Then, check the lamp status.)

The warning lamp turns off once the DTC is resolved. The warning lamp stays on until you complete the check necessary to resolve the DTC.

If the DTC is resolved, the warning lamp turns OFF during the same ignition cycle.

If the vehicle starts within 19 minutes after the replacement of the wheel of the stopped vehicle, the TPMS Malfunction Indicator on the instrument cluster illuminates.

The above symptom is due to communication failure between the BCM and the replaced TPMS ID.

This communication failure indicator turns off in 19 minutes after the vehicle stops through the BCM's automatic learning process of TPMS ID. (When driving the vehicle after stopping for more than 19 minutes, the indicator turns off automatically.)

Lamp ON: It is on simultaneously with the tread lamp. It Indicates the position of tires with low pressure and air leaks.

Lamp OFF: OFF simultaneously with the tread lamp.

CAUTION: If the wheel position changes while driving, the system assumes the previous state, but the warning light illuminates correctly when the current driving position is determined.

NOTE:

Tread warning lights and wheel position warning lights may light up due to sudden changes in the outside temperature (especially in winter) and influences from driving.

When the warning lamp turns on, check the inflation pressure and then inflate it to the specified tire pressure.

System Defect

General operation: The system detects many input elements to identify potential defects. The priority of a defect depends on its cause. Some defects cannot be diagnosed with DTC.

In order to diagnose more symptoms of the fault when the ignition line malfunctions, you must check the warning lamp when you turn the ignition on. Check whether the warning lamp turns on and then off.

Function: By detecting the pressure, temperature, acceleration and battery condition, transmit information to ECU by a wireless RF.

Wheel location is recognized by comparing the wheel Pulse of ECS (ABS) and acceleration values of the sensor (High Line).

Structure and features: There are four sensors mounted in each wheel of the vehicle.

Frequency conversion type is FSK, and High Line is used in common.

Modes: Shipping mode, stop mode, drive mode, and automatic location learning mode.

Valve type: Snap-in type [rubber valve]

Screw: Screw T10 [Continental Certified Parts]

MCU: ATIC 149 [Infineon]

Battery type: CR2032 Type

TPMS LEARNING

TPMS Automatic Location Learning

The wheel angular velocity of wheels is different from each other in the following cases:

1) Slip for each axis occurs differently.

2) Rotation radius (the radius of curve) for each wheel is different.

3) Tire wear, internal pressure, tire specifications, etc. for each tire are different.

TPMS sensor transmits the RF signal only in a specific phase (the angle of the tire) in the learning mode.

TPMS receiver checks each tire phase (tire angle) information on receiving RF signals from the sensor.

Every time RF signals from sensor IDs 1, 2, 3 and 4 are received, the ID with the highest correlation among the phase of each collected wheel is transmitted. (In other words, each time RF signal is received, the phase of the tire is transmitted to the most constant wheel.)

TPMS sensor transmits the RF signal at intervals of 16 seconds in the learning mode.

After stopping or parking for more than 19 minutes, automatic learning function in every driving position is performed.

The mode is converted to Parking Mode when stopped or parked for more than 15 minutes. When acceleration of over 4g (15-20 km/h) is detected in Parking Mode, it is converted to First Block Mode.

TIRE PRESSURE SENSOR REMOVAL AND INSTALLATION

Wheel Removal and Installation

Removal/Installation

1) Remove the wheel and tire.

NOTE: When using an impact wrench, final tightening torque should be checked using a torque wrench with the vehicle tires not being fully loaded with the vehicle weight.

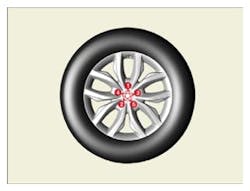

2) When installing, tighten the hub nuts as indicated in the top diagram.

TPMS Replacement

1) Remove the tire.

2) Remove the screw using torx driver (A) as shown above in Fig. 2.

CAUTION:

When installing the bead brake, make sure that it does not come in contact with the TPMS sensor. Be careful not to damage the TPMS sensor when installing the bead brake near the TPMS sensor.

3) Remove the sensor housing (A) in the direction of the arrow in Fig. 3.

4) Using a valve mounting tool, pull the sensor housing through the hole. NOTE: Cut the rubber under the valve.

5) Apply the surface of the new valve with lubricant and install it in the valve hole of the wheel. Specified lubricants: Soap water or YH100 (Lubricants for tire installation)

NOTE: After applying lubricant, install the valve within five minutes. (After five minutes, relubricate.)

CAUTION: If the lower part of the TPMS sensor valve is not properly mounted on the wheel, sealing will not work properly. All of the valleys of the valve body must be pulled through the hole.

6) Apply soapy water or lubricant to the upper and lower beads of the tire.

7) Place the TPMS sensor at 5 o'clock from the head of the tire changer to mount the bottom bead.

8) Rotate the wheel clockwise and press the tire at 3 o'clock to mount the lower bead.

CAUTION: Mount the tire on the wheel so the bead hits the rim edge (at 6 o'clock) behind the sensor.

9) To install the top bead, press the tire at 3 o'clock and turn the wheel clockwise.

10) Inflate the tire until the bead gets set.

11) Adjust the tire pressure according to the standard pressure.

Tire

235/65 R17 : 240 kPa (35 psi)

235/55 R19 : 250 kPa (36 psi)

12) In case of TPMS sensor failure, TPMS sensor learning is required. Replace the failed sensor with a new unit and perform TPMS sensor learning.

About the Author

Mitchell 1

Information for this column comes from the tire pressure monitoring systems data in ProDemand, Mitchell 1's auto repair information software for domestic and import vehicles. Headquartered in San Diego, Mitchell 1 has provided quality repair information solutions to the automotive industry since 1918. For more information, visit www.mitchell1.com.