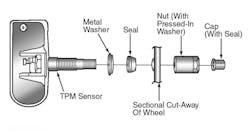

Figure 1: Identifying tire pressure sensor components (1 of 2).

SUBJECT VEHICLE: 2007-09 Dodge Durango.

RELEARN PROCEDURE? Yes.

SPECIAL TOOLS NEEDED? Yes, a TPM-RKE Analyzer tool to program sensor IDs.

The tire pressure monitoring system (TPMS) on the 2007-09 Dodge Durango monitors air pressure in the four road tires and the spare tire (if the vehicle is equipped with a full-size spare).

The TPMS uses radio and sensor technology to monitor tire air pressure levels. Sensors, mounted to each road wheel as part of the valve stem, monitor tire pressure, air temperature inside the tire, wheel acceleration and the sensor internal battery status for all four active road tires.

The sensor will broadcast this information, along with a unique 32-bit ID, to a central receiver circuit located inside the Wireless Control Module (WCM). If a warning or fault condition exists, the WCM will send a message request to illuminate the low pressure warning light and to sound a chime.

NOTE: If a tire pressure sensor has been replaced, the tire pressure sensors must be retrained. See reset procedures.

The TPMS remains active even if no tire pressure-related message is displayed. The sensors lay dormant (park mode), then wake and start transmitting (drive mode) when the vehicle first reaches speeds over 15 mph. Once the wheels stop rotating for a period of approximately 20 minutes, the sensors shut down until again awakened.

While in park mode, the sensors still transmit approximately once every 13 hours to let the receiver know air pressure status at that time. If a system fault is detected, the indicator light will flash on/off for 60 seconds.

Warning, warning!

If the warning light is lit continuously due to low pressure in one or more tires, adjust tire inflation to specification. The light will remain on until the tire pressure is properly set. NOTE: Tire pressure may increase from 2 psi to 6 psi during normal driving conditions. Do not reduce this normal pressure build up.

After adjusting air pressure in a tire, allow approximately two minutes for the message or indicator lamp to go out. If the warning light is flashing on/off for 60 seconds, there is a problem in the TPMS. See appropriate manufacturer service information.

Reset procedures

NOTE: If a tire pressure sensor has been replaced, the TPMS needs to relearn tire pressure sensor IDs. If the warning light is lit continuously due to low pressure in one or more tires, adjust tire inflation to specification. The light will remain on until tire pressure is properly set. After adjusting air pressure in a tire, allow approximately two minutes for the message or indicator lamp to go out.

Figure 2: Identifying tire pressure sensor components (2 of 2).

Using a radio frequency (RF) signal, each sensor transmits tire pressure data approximately once every minute. Each sensor’s transmitter broadcast is uniquely coded so that the WCM can monitor the state of each of the sensors on the four rotating road wheels. The WCM automatically learns and stores the sensor’s ID while driving after a sensor has been replaced.

There is no formal retraining procedure necessary. Drive vehicle for a minimum of 10 minutes while maintaining a continuous speed above 15 mph. During this time, the system will learn the new sensor ID code and will clear any DTCs automatically. If a sensor cannot be trained, see appropriate manufacturer service information.

The sensor IDs can also be programmed using the TPM-RKE Analyzer tool. Scan each TPM sensor at each road wheel, and store each Sensor ID in the correct location (left-front, left-rear, right-front and right-rear).

Connect the TPM-RKE Analyzer tool to the scan tool. Then follow the programming steps outlined in the diagnostic scan tool for “Program Tire Pressure Sensor ID w/ TPM Tool” under “MISC” for the “WCM/WIRELESS CONTROL MODULE.”

Demounting/mounting procedures

1. Remove tire and wheel assembly from vehicle. CAUTION: The tire should be demounted from the wheel using the tire changer manufacturer’s instructions. NOTE: If a tire pressure sensor has been replaced, the tire pressure sensors must be retrained. See reset procedures.

2. Demount tire from wheel following tire changer manufacturer’s instructions while paying special attention to the following to avoid damaging the pressure sensor:

• When breaking the tire bead loose from the wheel rim, avoid using the bead breaker in the area of the sensor. That includes both front and rear beads of the tire. See Figure 3.

Figure 3: Demounting tire with tool.

[PAGEBREAK]

• When preparing to demount the tire from the wheel, carefully insert the mounting/demounting tool at the valve stem +/-10°, and then proceed to demount the tire from the wheel. Use this process on both the upper and lower tire beads.

NOTE: Wheels and tires are match-mounted at the factory. Before demounting a tire from its wheel, a reference mark should be placed on the tire at the valve stem location, to ensure that it is remounted in the original position on the wheel.

For match-mounting procedures, refer to appropriate manufacturer service information.

3. Using a thin-walled socket, remove the special nut retaining the sensor to the wheel. While removing the nut, hold pressure against the rear of the metal valve stem to keep the valve stem from pushing rearward, which could damage the antenna strap. See Figure 2.

4. Remove the sensor from the wheel. See Figure 4.

Figure 4: Removing and installing tire pressure sensor.

Installation

1. Wipe area clean around the sensor/valve stem mounting hole in the wheel. Make sure the surface of the wheel is not damaged. CAUTION: To avoid damaging the sensor antenna strap, hold pressure against the rear of the metal valve stem while the sensor is inserted through wheel mounting hole and nut is installed. See Figures 2 and 4. NOTE: Before reinstalling an existing tire pressure sensor, replace seal and metal washer at the base of the valve stem to ensure proper sealing. See Figure 1.

2. Insert the sensor through the wheel as shown in Figure 4 keeping pressure against the rear of the metal valve stem. The potted side of the sensor is to be positioned toward the wheel. Do not attempt to mount the sensor otherwise, or damage may occur. Install the sensor nut (with pressed-in washer) by hand. See Figures 4 and 5. NOTE: Before tightening the sensor nut, push downward on the sensor housing in an attempt to make it flush with the interior contour of the wheel.

Figure 5: Installing tire pressure sensor.

3. Using a thin-walled socket, install the sensor nut. While holding the sensor in position, tighten the sensor nut to 71 in.-lbs. CAUTION: Over-torqueing the sensor nut by as little as 88 in.-lbs. may result in sensor separation from the valve stem. Under this condition, the sensor may still function; however, the condition should be corrected immediately.

4. Mount the tire on the wheel following the tire changer manufacturer’s instructions, paying special attention to the following to avoid damaging the tire pressure sensor:

• Rotating wheel tire changers — once the wheel is mounted to the changer, position the sensor valve stem approximately 180 degrees from the head of the changer in a clockwise direction before rotating the wheel (also in a clockwise direction) to mount the tire. Use this procedure on both the upper and lower tire beads. See Figure 6.

Figure 6: Mounting tire using rotating wheel machine.

• Rotating tool changers — position the wheel on the changer so that the sensor valve stem is approximately 180 degrees from the head of the changer in a clockwise direction from the mounting end of the tool. See Figure 7. Make sure the sensor is clear of the lower bead breaker area to avoid damaging the sensor when the breaker rises. Rotate the tool in a counterclockwise direction to mount the tire. Use this procedure on both the upper and lower tire beads.

Figure 7: Mounting tire using rotating tool machine.

5. Adjust air pressure to specification. Make sure the original style valve stem cap is securely installed to keep moisture out of the sensor. Install the wheel and tire assembly on the vehicle.

6. Drive the vehicle for a minimum of 10 minutes while maintaining a continuous speed above 15 mph. During this time, the system will learn the new sensor ID code and will clear any DTCs automatically. If a sensor cannot be trained, see appropriate manufacturer service information. ■

Information for this column comes from Mitchell 1’s ”Tire Pressure Monitoring Systems Guide” for domestic and import vehicles, updated through 2012. Headquartered in Poway, Calif., Mitchell 1 has provided quality repair information solutions to the automotive industry for more than 80 years. For more information, visit www.mitchell1.com.