SUBJECT VEHICLES: Lexus RC F 2015-19, RC 200T 2016-17, RC 300 2016-19 and RC 350 2015-19.

SPECIAL TOOLS NEEDED? A Toyota Techstream must be used.

The tire pressure monitoring system (TPMS) in Toyota’s luxury line of Lexus vehicles is designed to provide warning when tire inflation pressure of one or more tires (including the spare tire) is low. A tire pressure monitoring valve sub-assembly equipped with a tire pressure sensor/transmitter is installed in each tire and wheel assembly.

The sensor measures the tire pressure and transmits the measured value and transmitter ID to the tire pressure monitoring receiver assembly on the body as radio waves, which are then sent to the tire pressure monitor engine control unit (ECU). If the transmitter ID has already been registered, the ECU compares the measured tire pressure value and the warning threshold pressure value.

When the value is less than the warning threshold pressure value registered in the tire pressure monitor ECU, the tire pressure warning light on the instrument cluster will turn on.

TIRE PRESSURE MONITOR WARNING LIGHT

NOTE: The tire pressure warning light may turn on due to natural causes such as natural air leaks or tire pressure changes caused by temperature. In this case, adjusting the tire pressure will turn off the warning light.

When the tire pressure warning light does not go off, or when it comes on during driving, check tire pressure (including spare tire) and adjust as necessary. The warning light should turn off a few minutes after air is put into a deflated tire. If the tire pressure warning light comes on after blinking for 1 minute frequently when the engine switch is turned to the “ON” position, there is a malfunction in the TPMS. See the appropriate manufacturer service information.

The spare tire is also equipped with the tire pressure warning valve and transmitter. The tire pressure warning light will turn on if the tire inflation pressure of the spare tire is low. If a tire goes flat, even though the flat tire is replaced with the spare tire, the tire pressure warning light does not turn off. Replace the spare tire with the repaired tire and adjust the proper tire inflation pressure. The tire pressure warning light will turn off after a few minutes.

TPMS RESET PROCEDURES

NOTE: If the tire pressure sensor and/or tire pressure monitor ECU are replaced, the transmitter ID needs to be registered in the tire pressure monitor ECU.

TIRE PRESSURE SENSOR REGISTRATION

NOTE: When a tire pressure sensor and/or tire pressure monitor ECU are replaced, all the tire sensors must be registered. To perform this procedure, a Toyota Techstream must be used.

Transmitter initialization

NOTE: Initialization can be confirmed through the tire pressure warning light.

- The order in which the data is received is random. If the signals from all the tire pressure warning valve and transmitters are received, initialization is completed.

- Initialization is completed when the Data List “ID Tire Inflation Pressure” display shows the correct pressures.

- It may take a few minutes until the values are displayed. If the values are not displayed after a few minutes, perform troubleshooting according to the inspection procedure for DTCs C2121/21 to C2124/24.

- If initialization has not been completed successfully, DTC C2177/77 is stored after a vehicle speed of 23 mph (37 km/h) or more is detected for 20 minutes or more.

- During test mode (sensor check mode), the system will not change to initialization mode even if the tire pressure warning reset switch is pushed.

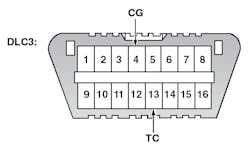

- Initialization can be terminated by connecting terminals 13 (TC) and 4 (CG) of the DLC3 (see Figure 1).

1) Set the tire pressure to the specified value.

2) Turn the engine switch on (IG).3) Press and hold the tire pressure warning reset switch for 3 seconds or more until the tire pressure warning light blinks 3 times (see Figure 2).

4) Turn the engine switch off.

5) Connect the Techstream to the DLC3.

6) Turn the engine switch on (IG) and turn the Techstream on.

7) Enter the following menus: Chassis / Tire Pressure Monitor / Data List.

8) Check that initialization has been completed.

9) Confirm that the tire pressure data of all tires is displayed on the Techstream screen.

Register transmitter ID

NOTE: The transmitter ID is written on the tire pressure warning valve and transmitter. It is not possible to read the transmitter ID after installing the tire onto the wheel.

Therefore, make a note of the transmitter ID before installing the tire.

NOTE: If the ID registration step is not completed within 300 seconds, ID registration will be canceled.

1) Set the tire pressure of all wheels (including the spare tire) to the pressure specified on the tire and loading information label.

2) With ignition OFF, connect the Techstream to DLC3.

3) Turn ignition switch to ON position. Turn the Techstream ON.

4) Enter the following menus: Chassis / Tire Pressure Monitor / Utility / ID Registration. NOTE: If registration is not completed within 300 seconds, ID registration is canceled.

5) Perform the procedures displayed on the Techstream.

NOTE: After all IDs are registered, DTC C2126/26 is stored in the tire pressure warning ECU and the tire pressure warning light blinks for 1 minute and then comes on. When the tire pressure warning ECU successfully receives radio waves from all the transmitters whose IDs are stored in the ECU, DTC C2126/26 is cleared and the tire pressure warning light goes off.

Confirmation of transmitter ID registration

NOTE: It may take up to approximately 2 or 3 minutes to update the tire pressure data. If the values are not displayed after a few minutes, perform troubleshooting according to the inspection procedure for DTCs C2121/21 to C2124/24.

1) Enter the following menus: Chassis / Tire Pressure Monitor / Data List.

2) Read the “ID Tire Inflation Pressure” values.

3) Confirm that the tire pressure data of all tires (except the spare tire) is displayed on the Techstream screen.

4) If normal pressure values are displayed, the IDs are registered correctly.

DEMOUNTING/MOUNTING PROCEDURES

CAUTION: The tire should be demounted from the wheel using the tire changer manufacturer’s instructions.

Use the following information to avoid damage during the demounting/mounting procedures.

NOTE: When a tire pressure sensor and/or tire pressure monitor ECU are replaced, the sensor for all of the tire pressure warning valve and transmitters must be registered. See “Reset procedures.” TPMS requires no action when tires are rotated or tires are inflated to specification.

TIRE PRESSURE SENSOR

CAUTION: Do not try to install a tire pressure sensor in a steel wheel or aftermarket wheel. Use only in original style factory wheels.

CAUTION: The use of tire sealants is strictly prohibited for vehicles equipped with the TPMS. Tire sealants can clog tire pressure sensors.

CAUTION: Be sure to reinstall tire valve caps, or dirt or moisture could get into the valve core and cause air leakage. Use only the original valve cap.

If any other valve cap is used, it may corrode or melt, and become extremely difficult to remove.

NOTE: The average life of the grommet of the tire pressure monitor valve sub-assembly is approximately 5 years, at which time it must be replaced. If the valve is leaking air, is less than 5 years old and there is no problem with grommets, retighten the valve nut to 35 in.-lbs. (4 N.m).

Whenever the tires must be replaced, replace grommets for the tire pressure sensors as well.NOTE: If the tire pressure valve sub-assembly is going to be replaced, make a note of the 7-digit number (transmitter ID) before installation, as it cannot be seen after sensor is installed (see Figure 3). Whenever a new sensor is installed, it will need to be registered in the tire pressure monitor ECU.

Removal

1) When replacing a wheel or tire, tire pressure sensors must be set up in one of the following ways:

- Remove the sensor from the old wheel and install it to the new wheel. Keep the same wheel with the tire pressure sensor and replace only the tire.

- Use a new wheel and sensor (the new sensor must be registered after installation).

2) Remove the wheel. Remove the valve core and cap, and release air from the tire.

NOTE: Keep the removed cap, valve core, nut and washer.

3) After ensuring that air is sufficiently released, remove the nut and washer that is used to fix the tire pressure monitor valve sub-assembly and drop the sensor inside the tire.

NOTE: Be careful not to damage the tire pressure monitor valve sub-assembly due to interference between the sensor and tire bead.4) After dropping the tire pressure monitor valve sub-assembly into the tire, disengage the bead using the shoe of the tire remover (see Figure 4).

5) Remove the bead on the upper side in the usual operation.

6) Take out the sensor from the tire and remove the bead on the lower side as in usual operation.

NOTE: Do not reuse the grommet.

7) Remove the inner grommet from the tire pressure monitor valve sub-assembly (see Figure 5).

NOTE: Tire pressure sensor is powered by a lithium battery. When disposing the sensor, remove the battery and dispose of properly.

Installation

1) Install a new inner grommet to the tire pressure warning valve and transmitter.

2) Insert the tire pressure monitor valve into the valve installation hole. Insert from the inside of the rim so that the print surface can be seen. Check for the following:

- Check that there is no visible deformation on the transmitter.

- Check for foreign matter on the inner grommet and around the rim hole.

- If installed in the reverse direction, the tire pressure monitor valve may be damaged or fail to transmit signals when running at high speed.

- If installing a new tire pressure monitor valve, write down the ID number before installation (see Figure 3). It is necessary to register an ID in the ECU after installation.

3) Install the washer on the tire pressure monitor valve from the rim side and tighten the nut to 35 in.-lbs. (4 N.m), see Figure 5. Check for the following:4) Ensure there is no foreign matter on the washer and nut.

5) If the tire pressure monitor valve was removed, check that there is no damage or cuts, and no foreign matter such as mud, dirt or sand attached to the grommet. Replace the grommet with a new one if any of these defects are found.

6) Check that there is no oil, water or lubricant around the rim hole, tire pressure monitoring valve, washer and nut. Failing to do so may result in improper installation.

CAUTION: If the sensor is positioned outside this area, it generates interference with the tire bead, causing possible damage to the sensor.

If the use of lubricant is required when installing the bead, do not apply the lubricant directly to the tire pressure warning valve and transmitter.7) Set the wheel disc to the mounting machine and install the lower tire bead. Position the main body of the sensor in the shaded area as shown in the illustration (see Figure 6).8) While making sure that the tire bead and tool do not interfere with the main body of the sensor and that the sensor is not clamped by the bead, install the upper bead.

NOTE: If the valve nut is loose after inflating the tire, retighten the nut to the specified torque.9) When putting air into the tire, first install the valve core on the stem of the tire pressure warning valve and transmitter.

10) Install tire and wheel assembly.

11) When a new sensor is installed, the ID code will need to be registered. See “Tire pressure sensor registration” under “Reset procedures.” ?

Torque specifications

Component ....................... Ft.-lbs. .... (N.m)

Wheel nut .......................... 76 ........... (103)

.............................................. In.-lbs. ... (N.m)

Tire pressure sensor nut ... 34 .......... (4)