SUBJECT VEHICLE: 2006-09 Jeep Commander.

SENSOR IN TIRE? No (sensors are mounted to each wheel).

RESET PROCEDURE? Yes (by driving the Commander for a minimum of 10 minutes while maintaining a continuous speed of above 20 mph for 2006 models and 15 mph for 2007-09 models).

SPECIAL TOOLS NEEDED? No.

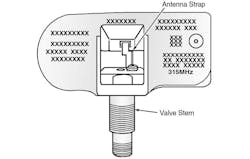

The tire pressure monitoring system (TPMS) in the 2006-09 Jeep Commander uses radio and sensor technology to monitor air pressure levels. Sensors are mounted to each wheel as part of the valve stem. Each sensor sends data to a central receiver circuit inside the Wireless Control Module (WCM). On premium models, the sensor transponders are mounted in the wheel housings.

If a warning condition exists, the WCM will send a message request to illuminate the low pressure warning light and to sound a chime.

The TPMS will stay active even if no pressure-related message has been displayed. When the Commander reaches speeds of more than 20 mph, the sensors wake and start transmitting.

Once the vehicle’s wheels stop rotating for 20 minutes, the sensors shut down. While in this state (Park Mode), the sensors still transmit data once every 13 hours.

If a system fault is found, the indicator light will flash on and off for 75 seconds, then will stay on continuously.

On some models, if one of the Commander’s tires has been replaced by a spare that is not equipped with a tire pressure sensor, the indicator light will flash for three seconds every 10 minutes.

In with the new

Before installing a new sensor, make sure it is the correct sensor.

Sensors can be identified by a black sensor body with a white outline oval insignia.

Also keep in mind that the cap used on the Commander’s valve stem contains an O-ring seal. A regular valve stem cannot be used as a substitute. Any time a sensor is installed in a wheel, a new seal and washer must be installed on the stem to ensure an airtight seal. In addition, the nut and the valve core should be replaced.

[PAGEBREAK]

Follow these steps to remove the old sensor:

1. Remove the tire and the wheel from the vehicle and let the air out of the tire.

2. Remove the tire from the wheel following the tire changer manufacturer’s instructions.

After you remove the old sensor, you are now ready to install the new one.

Follow these steps:

1. Replace the valve core, seal and metal washer at the base of the valve stem to ensure a proper seal.

2. Wipe the area around the sensor valve/steam mounting hole in the wheel, making sure it is clean.

3. Insert the sensor through the wheel and keep the pressure against the rear of the metal valve stem. Position the potted side of the sensor toward the wheel.

4. Push downward on the sensor housing to make it flush with the contour of the wheel.

5. Using a thin-walled socket, install the sensor nut. While holding the sensor in place, tighten the nut to 53 in.-lbs. for model year 2008 or later. For model years 2006-07, tighten it to 71 in.-lbs.

6. Mount the tire on the wheel. Position the sensor valve stem 280 degrees from the head of the changer in a clockwise direction before rotating the wheel to mount the tire. Use this procedure on both the upper and lower tire beads

7. Adjust the air pressure level to specification.

8. Make sure the original valve stem cap is securely installed to keep moisture out of the sensor.

9. Install the wheel and tire on the vehicle.

Any time a sensor has been replaced, the TPMS has to undergo a relearn process, in which the TPMS relearns the tire pressure sensor IDs.

Using a radio frequency signal, each sensor transmits tire pressure data once every minute. Each sensor’s broadcast is uniquely coded so that the WCM can monitor the state of each of the sensors on the four wheels.

The WCM automatically learns and stores the sensor’s IDs while driving.

This is achieved by driving the Commander for a minimum of 10 minutes while maintaining a continuous speed of above 20 mph for 2006 models and 15 mph for 2007-09 models. During this time, the system will learn the new sensor ID code. ■

Information for this column comes from Mitchell 1’s ”Tire Pressure Monitoring Systems Guide” for domestic and import vehicles through 2009. Headquartered in Poway, Calif., Mitchell 1 has provided quality repair information solutions to the automotive industry for more than 80 years. For more information, visit www.mitchell1.com.

Figure 1