They’re becoming a greater fact of life for tire dealers. Tire pressure monitoring systems (TPMS) have been required on all new vehicles under 10,000 pounds since 2007. But the technology was first required on 10% of vehicles in 2001. Now, some of those older sensors are reaching the end of their service life.

“Battery life for the very early versions was 3-5 years, and now the later versions are 5-7 years,” says Gary Luginbuhl, training manager at Myers Tire Supply. “We really don’t know how long they’ll last yet because nothing’s been out there that long. The early ones are starting to fail, the ones that were out there in 2001-2002.”

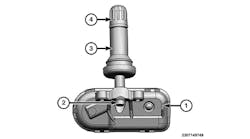

The pressure sensor transmitters (one transmitter mounted inside each wheel) monitor inflation data and send an FM radio signal to the system’s antenna and receiver, which then sends a digital signal to an electronic control unit (ECU).

Today, the TPMS (where actual tire inflation pressure is monitored) is referred to as a direct system. The system is calibrated to alert the driver when one or more tires have lost 20-25% of the programmed inflation pressure.

The basic three

Three basic “styles” of TPMS sensor/transmitters are available: banded, snap-in and clamp-on. Banded sensors are affixed to the inside of the wheel using both a positioning adhesive (peel off) and a large diameter worm-drive clamp (the wheel valve is the standard valve style that has been in use for decades). Both clamp-on and snap-in sensors feature the valve stem as an integral part of the sensor. A clamp-on sensor mounts via the wheel’s valve hole and is secured with a mounting nut. It is sealed with a separate grommet. The snap-in style features a traditionally mounted rubber valve style.

It’s important to quickly identify a snap-in style sensor. The valve stem caps are longer than a traditional stem cap, and (with the cap removed) you’ll notice a beveled brass surface at the base of the cap mating area.

Banded TPMS sensors are still found on some Fords. Other makes/models utilize clamp-on or snap-in sensor styles, where the valve is an integral part of the sensor. Another integral part of the sensor is the frequency in which it transmits.

“There are two different sensor frequencies for domestic and import: 434 megahertz is the import (foreign makes that are sold in this country); and 315 megahertz are the domestic, GM and Ford,” says Luginbuhl. “It’s not 100% because there are some Nissans that are 315 megahertz.”

There are several sources for OEM TPM systems: Schrader International, Borg Warner Beru Systems GmbH and Pacific Industrial Co. Ltd.

Schrader systems are found on Ford, Chrysler, GM and Nissan/Infiniti applications. Pacific systems are found on certain Lexus vehicles, and Beru systems are used on Mercedes-Benz, Porsche, BMW, Audi/VW and Land Rover models.

The majority of OE TPMS sensors are stem-mounted. The primary reason involves diagnostic capabilities. If the sensor is band-mounted and deeper inside the wheel, it’s more difficult for the signal to pass to the diagnostic tool, whether the system uses an RF signal or a magnetic signal.

Universal sensors to the rescue

“When you look at brake pads, starter motors, wiper blades, oil filters, exhaust systems and so on, the OEs never, ever standardized anything,” Luginbuhl explains. “They did the same thing with TPMS. What they ended up doing was creating a gridlock of technology and service support for the aftermarket dealers, our customers. The OEs went with multiple sensor manufacturers, multiple signal protocols and numerous shapes and styles of sensors to react to the mandate.”

Currently there are an estimated 75 versions of TPMS sensors in OE use. As a result, it’s impossible (or at least extremely impractical) for any shop to stock enough sensors to accommodate all makes/models/years.

“The big issue for the tire dealer has been that there are 75 of these on the market and they don’t know what kind of vehicle is going to pull into their shop,” says Luginbuhl. “You’ve got a minimum of four each and these are $50 to $150 each, so for a dealer to stock 75 different types – it’s not going to happen. The OEs took the good old universal rubber snap-in tire valve that we all grew up with, that you can snap into any vehicle anywhere, and they made the tire valve into a make-model-year specific device, just like a starter motor. That’s what the dealers have to deal with now.”

[PAGEBREAK]With everything dealers have to deal with now, universal TPMS sensors make life easier. With universal tire pressure sensors, you can take a new “blank” sensor and program it for the application.

While universal sensors don’t accommodate 100% coverage, they each cover large percentages of the current market. The makers are continually obtaining protocol information from the auto makers, so if certain application information hasn’t yet been made available to the aftermarket, it’s a waiting game for the sensor makers.

31 Inc. Xtra Seal Smart Sensor

This universal programmable TPMS sensor from 31 Inc. comes with a free programming/activation tool with the bundles assortment. 31 Inc. says it is easy to learn and to use. The Smart Sensor programs in seconds and eliminates the need for dealers to stock a large inventory of sensors.

Application coverage includes GM, Toyota, Ford, Honda, Chrysler, Nissan, Volvo and others. Additional applications are in the works. The Smart Sensor can be triggered by the other aftermarket TPMS tools, notes the company.

Continental VDO Redi-Sensor

This sensor from Continental VDO is designed to cover all (available) protocols in a “shotgun” approach. The sensor is pre-programmed with all system protocols. It sends out all frequency protocols (multiple data commands in a continuous wave), allowing the vehicle’s ECU to grab the one that fits. These sensors are pre-programmed, and are not programmable (similar to a read-only CD that can’t be over-written). Basically, install and go.

The up-side: The sensor is already programmed with multiple protocols, so no programming is needed. The down-side: You can’t update it with new programming in the future (if a newer/different protocol is required).

Sens-It from Myers Tire Supply

In this system from Myers Tire Supply the sensor is blank (again, like a blank CD). Programming the ID is accomplished via the Sens-It Web site. A docking station pad connects to your PC via a USB cable. Lay the blank sensor onto the pad, go to the Web site, and follow the simple prompts. Enter the vehicle’s VIN to obtain the correct protocol information and assign a wheel location.

The information uploads, and the new sensor is now programmed. During a production run of the vehicle, the OE may have changed the sensor model from one run to another. By using the VIN, you program the new sensor with exactly the same data as the original sensor that was installed during vehicle production.

The iORO from Oro-Tek USA

The iORO from Oro-Tek USA features the company’s Multi Vehicle Protocol (MVP) so tire dealers can service 70% of all vehicles with just one SKU. iORO installs and functions the same as the OE sensors it replaces and works with tools that tire shops already own so there are no new tools to buy, says the company.

iORO, and all Oro-Tek TPMS sensors, feature a 35-degree adjustable stem to fit more vehicles. A two-piece design allows replacement of the valve stem independent of the sensor. Oro-Tek offers a complete line of TPMS sensors that provide tire dealers and distributors the ability to service 97% of all vehicles.

OTC TPR Tool from SPX Service Solutions

The new Tire Pressure Reset (TPR) Tool from SPX Service Solutions programs the universal EZ-Sensor and works with the multi-application Redi-Sensor. This simplifies TPMS service for tire dealers and helps lower inventory costs.

SPX says the tool saves time by eliminating the need for relearn procedures, and it has also been tested and verified to work with the Continental VDO Redi-Sensor, right out of the box. It is also compatible with the Genisys EVO. TPR updates are available via the Internet.

Schrader International/Bartec USA EZ-Sensor

This sensor was jointly developed by Schrader International Inc. and Bartec USA (Bartec has long been involved in TPMS, making test/verification equipment for OE vehicle production, and now offers hand-held units for shops).

The sensor is “blank” (like a blank CD), requiring a Bartec TPMS tool for programming. The tool reads data from the original sensor (reading the sensor’s “fingerprint”). A new EZ-Sensor is then placed in the tool’s cradle. The tool then imprints the original sensor’s information (its fingerprint) into the new universal sensor, in effect, creating a replicate (clone). If you make a mistake during the imprinting process, you can start over, since the EZ-Sensor is “re-writable.”

The up-side: The sensor is easily programmable and can be re-programmed at whim. The down-side: This sensor is dedicated (for programming) for use with only the Bartec tool, and the tool must be updated annually at a cost of about $300/year (in order to update the programming capabilities to meet ever-changing OE vehicle protocols).