SUBJECT VEHICLE: 2010 Ford F-Series.

SENSOR IN TIRE? No (sensors/transmitters are installed in wheels).

RESET PROCEDURE? Yes.

SPECIAL TOOLS NEEDED? Yes (T10 Torx, TPM Activation Tool (204-363).

When a 2010 Ford F-Series vehicle is moving 20 mph or greater, the tire pressure monitoring system’s wheel-mounted tire pressure sensors transmit radio frequency signals to the Smart Junction Box (SJB) every 60 seconds. Each transmission is compared against a low-pressure limit (pressure listed on the vehicle certification label minus 25%, which will be about 6 to 9 psi). If a tire’s pressure falls below this limit, the SJB sends a message to the instrument cluster, which then illuminates the low pressure warning indicator.

To remove an old sensor, follow these steps.

1. Remove the wheel and tire. The valve stem is connected to the TPMS sensor, so do not pull the valve stem from the wheel to avoid damaging the sensor.

2. Remove the valve stem core and fully deflate all air from the tire.

3. Remove the tire from the wheel following the tire manufacturer’s directions.

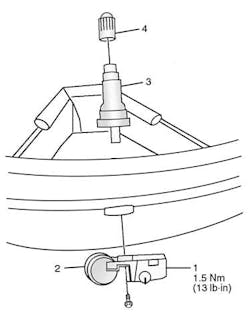

4. Remove the TPMS sensor from the valve in the following sequence (see Figure 1):

a. Using a T10 Torx, remove the valve stem-to-TPMS sensor screw.

b. Carefully and firmly pull the sensor straight down and separate it from the valve stem.

5. Using a suitable valve stem puller and a wood block, remove the valve stem from the wheel.

6. If the TPMS sensor is being reused, inspect the TPMS sensor for damage and install new parts as necessary.

Before installing the replacement sensor, the valve stem must be installed onto the TPMS sensor and then installed into the wheel as an assembly.

Now you can install the replacement sensor by following these seven steps.

1. Install a new valve stem onto the TPMS sensor, tightening the valve stem-to-TPMS sensor screw to 13 in.-lbs. (1.5 Nm). It is important to pull the valve stem and TPMS sensor assembly through the wheel rim hole in a direction parallel to the valve stem hole axis.

2. Lubricate the valve stem with suitable fast-drying, corrosion-inhibiting tire bead lubricant and install the valve stem and TPMS sensor assembly into the wheel using a block of wood and a suitable valve stem installer. Do not mount the tire at this time.

3. Make sure the valve stem rubber is fully seated against the wheel.

[PAGEBREAK]

4. Position the wheel on the turntable of the tire machine, then lubricate and position the bottom bead of the tire on the wheel.

5. Mount the tire according to the tire manufacturer’s instructions being certain to position the machine arm at 6 o’clock with respect to the location of the valve to avoid damage to the sensor.

6. Inflate the tire to the pressure specified on the vehicle certification label on the driver door or door pillar.

7. Install the wheel and tire. NOTE: If a new sensor has been installed it must be activated and trained.

To activate the new sensor(s), follow these steps:

1. Turn the ignition switch to the “on” position.

2. Place the activation tool on the left-front tire sidewall at the tire valve stem. For each successful TPM sensor response a green light will flash and a beep will sound on the activation tool.

3. Press the test button on the activation tool to activate the TPM sensor. For best results, activate each sensor twice.

4. Perform steps 2 and 3 for each remaining tire.

Now you’re ready to train the new sensors.

1. Turn the ignition switch to the OFF position, then press and release the brake pedal.

2. Turn the ignition switch from the OFF position to the RUN position three times, ending in the RUN position. Don’t wait more than one minute between each key cycle.

3. Press and release the brake pedal.

4. Turn the ignition switch to the OFF position.

5. Turn the ignition switch from the OFF position to the RUN position three times, ending in the RUN position. Don’t wait more than one minute between each key cycle. It may take up to six seconds to activate a tire pressure sensor. During this time, the activation tool must remain against the sidewall of the tire.

6. Place the activation tool on the left-front tire sidewall at the tire valve stem. Press the test button on the activation tool. The horn will sound briefly to indicate that the tire pressure sensor has been recognized by the SJB.

7. Within two minutes after the horn sounds, place the activation tool on the right-front tire sidewall 180 degrees from the valve stem for strap and cradle type sensors or at the valve stem for valve stem-mounted sensors. Repeat procedure for the right-rear and left-rear tires.

When the tire training procedure is complete, the message center (if equipped) will display “Tire Training Complete.” For vehicles not equipped with a message center, successful completion of the training procedure will be verified by turning the ignition switch to the OFF position without the horn sounding. If the horn sounds twice when the ignition is turned off, the training procedure was not successful.

Information for this column comes from Mitchell 1’s ”Tire Pressure Monitoring Systems Guide” for domestic and import vehicles through 2010. Headquartered in Poway, Calif., Mitchell 1 has provided quality repair information solutions to the automotive industry for more than 80 years. For more information, visit www.mitchell1.com.