If a sensor within the tire pressure monitoring system (TPMS) of an Infiniti Q50, model years 2018-2020, is replaced it will need to be initiated. The TPMS is not affected by wheel and tire rotation.

TIRE PRESSURE SENSOR ID REGISTRATION

TPMS ID registration can be performed using one of the following procedures:

- Tire pressure sensor Activation tool (J-45295-A) with CONSULT (preferred method);

- Signal Tech II tool (J-50190) with CONSULT (preferred method);

- Signal Tech II tool (J-50190) without CONSULT

TPMS REGISTRATION WITH TIRE PRESSURE SENSOR ACTIVATION TOOL (J-45295-A) With CONSULT:

Turn the ignition switch ON;

Using CONSULT, select “WORK SUPPORT” in AIR PRESSURE MONITOR. Then select “ID REGIST;”

Select “start” on “ID REGIST” screen.;

Hold the tire pressure sensor activation tool (J-45295-A) against the side of the left front tire, near the valve stem;

With the tool held at a zero-to-15-degree angle to the tire, press and hold the tire pressure sensor activation tool button until the indicator lamp turns OFF (approximately five seconds);

Repeat steps four and five for the remaining tires in this order: right front, right rear and left rear;

When ID registration is complete, check the following pattern at each wheel: left front tire, right front tire, right rear tire and left rear tire;

- Turn signal lamp: two blinks

- CONSULT: “Yet (red)”

- “Done (green)”

After the ID registration procedure for all wheels is complete, press “end” on the CONSULT to finish ID registration.

TPMS REGISTRATION WITH SIGNAL TECH II TOOL (J-50190)

NOTE: The Signal Tech II must be updated with software version 1.1.48 or newer in order to perform the below procedures. The Signal Tech II software updates can only be downloaded from a CONSULT unit with ASIST. Other versions of ASIST will not show the updates.

With CONSULT

Adjust the tire pressure for all tires to the recommended value;

Turn the ignition switch ON;

Using CONSULT, select “WORK SUPPORT” in AIR PRESSURE MONITOR. Then select “ID REGIST;”

Select “start” on “ID REGIST” screen;

Turn on the Signal Tech II tool (J-50190);

Hold the Signal Tech II against the side of the left front tire, near the valve stem;

With the tool held at a zero-to-15-degree angle to the tire, select “Activate Sensor” from the main menu, then press and release the “OK” button to activate the sensor. Once the sensor is activated, the vehicle parking lamps will flash and the sensor ID will appear on the CONSULT screen;

Repeat steps six and seven for the remaining tires in this order: right front, right rear and left rear;

When ID registration is complete, check the following pattern at each wheel: left front tire, right front tire, right rear tire and left rear tire;

- Turn signal lamp: two blinks

- CONSULT: “Yet (red)”

- “Done (green)”

Once all sensors have been activated, select “End” on the CONSULT to finish ID registration.

Without CONSULT

Adjust the tire pressure for all tires to the recommended value;

Turn on the Signal Tech II tool (J-50190) and select “TPMS Check” from the main menu.

Select vehicle model and year.

When prompted, hold the Signal Tech II against the side of the left front tire, near the valve stem;

With the tool held at a zero-to-15-degree angle to the tire, press and release the “OK” button to activate the sensor. Once the sensor is activated, the tool will sound a tone and the tire pressure will be displayed.

Repeat steps four and five for the remaining tires in this order: right front, right rear and left rear;

When prompted, connect the tool to the data link connector. The tool will connect to the TPMS, read the VIN, read sensor IDs and check for TPMS DTCs. Along with DTCs detected, one of the following will be displayed next to each wheel:

- N/A - Not applicable because no ID found by the tool

- OK - Wheel and sensor are in original position

- NEW - New ID found compared to TPMS

- RT - Wheel has been rotated

- Low Press - Low tire pressure

If no DTC is present or the repair has been completed, press the “OK” button to register the IDs and clear DTCs.

Print a Signal Tech II Audit Report for your records. Refer to the Signal Tech II User Guide for instructions.

DEMOUNTING/MOUNTING PROCEDURES

CAUTION: The tire should be demounted from the wheel using the tire changer manufacturer’s instructions. Use the following information to avoid damage during the demounting/mounting procedures. Ensure that the wheel to be fitted is designed for sensor mount. There should normally be a mark to indicate this.

TIRE PRESSURE SENSOR REMOVAL

- Remove tire assembly. NOTE: If the tire is reused, apply a matching mark to the position of the tire road wheel valve hole for the purpose of wheel balance adjustment after installation;

- Remove valve cap and valve core and then deflate tire;

- Remove valve nut retaining tire pressure sensor and allow tire pressure sensor to fall into tire.

CAUTION:

- Verify that the tire pressure sensor is at the bottom of the tire while disengaging the tire beads;

- Be sure not to damage the road wheel or tire pressure sensor.

- Use the tire changer and disengage the tire beads;

- Apply bead cream or an equivalent to the tire beads;

- Set tire onto the tire changer turntable so that the tire pressure sensor inside the tire is located close to the road wheel valve hole;

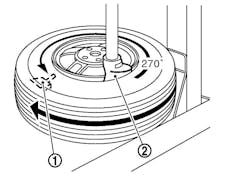

- Turn tire so the valve hole is at bottom and bounce so the tire pressure sensor is near the valve hole. Carefully lift tire onto the turntable and position valve hole(and tire pressure sensor 270 degrees from the mounting/demounting head. CAUTION: Be sure not to damage the road wheel and tire pressure sensor;

- Remove tire pressure sensor from tire;

- Remove the grommet seal;

- Remove the valve stem.

INSTALLATION

CAUTION: Replace valve stem assembly if the valve stem has deformations, cracks, damage or corrosion:

Apply bead cream or an equivalent to the tire beads;

Install the tire inside beads onto the road wheel;

Install valve stem to tire pressure sensor.

CAUTION:

- Never reuse grommet seal;

- Insert grommet seal all the way to the base.

Install grommet seal to the tire pressure sensor assembly;

Follow the procedure below and install the tire pressure sensor to the road wheel.

When valve stem assembly is replaced:

Set valve stem in the tire pressure sensor;

Install the washer in the valve stem, and then install seal in the valve stem. (TYPE 2 only)

CAUTION:

- Direction of the seal is checked.

- The cut part of the washer becomes in the center of the valve stem.

Check the condition of the valve stem before installing tire pressure sensor to the road wheel.

CAUTION: The base of valve stem must be positioned in the groove of the metal plate as shown in the figure to the left:

Hold tire pressure sensor as detailed below, and press the sensor in the direction shown by the arrow to bring it into absolute contact with the road wheel. After this, tighten the valve nut to the specified torque.

CAUTION:

- Never reuse valve core and valve cap;

- Check that the grommet seal is free of foreign matter;

- Check that the grommet seal contacts horizontally with the road wheel;

- Check again that the base of the valve stem is positioned in the groove of the metal plate;

- Manually tighten the valve nut all the way to the wheel. (Never use a power tool to avoid impact.)

Set the tire onto the turntable so that the tire changer arm is at a position approximately 270 degress from the tire pressure sensor. CAUTION: Be sure that the arm does not contact the tire pressure sensor;

Install the tire outer side beads onto the road wheel. CAUTION: When installing, check that the tire does not turn together with the road wheel;

Check the tire pressure for all wheels and adjust to the specified value. NOTE: Before adding air, align the tire with the position of the matching mark applied at the time of removal;

Install the tire to the vehicle;

Perform tire pressure sensor ID registration.

| Torque Specifications | ||

|---|---|---|

| Component | Ft.-lbs. | (N.m) |

| Wheel nut | 80 | (108) |

| INCH libs | Lbs | (N.m) |

| Tire Pressure Sensor Nut | 68 | (7.7) |

Information for this column comes from the tire pressure monitoring systems data in ProDemandR, Mitchell 1’s auto repair information software for domestic and import vehicles. Headquartered in San Diego, Mitchell 1 has provided quality repair information solutions to the automotive industry since 1918. For more information, visit www.mitchell1.com

About the Author

Mitchell 1

Information for this column comes from the tire pressure monitoring systems data in ProDemand, Mitchell 1's auto repair information software for domestic and import vehicles. Headquartered in San Diego, Mitchell 1 has provided quality repair information solutions to the automotive industry since 1918. For more information, visit www.mitchell1.com.