DESCRIPTION & OPERATION

The tire pressure monitor system warns the driver when a significant loss of tire pressure occurs in any of the equipped tires. If the tire is overinflated by more than 35 kPa (5 psi), the horn will sound multiple times and the turn signal lamp will continue to flash for several seconds after filling stops. When the recommended pressure is reached, the horn sounds once. If a new sensor has been installed or tire rotated, the vehicle must be stationary for about 20 minutes before the system can start the process of calculating correct sensor locations. For this to happen, the vehicle will need to be driven at a speed greater than 12 mph for about 10 min.

When the tire pressure system detects a significant loss, or gain of tire pressure, the tire pressure monitor indicator icon is continuously illuminated on the instrument cluster and if equipped, a check tire pressure type message is displayed on the driver information center. Both the indicator icon and driver information center message can be cleared by adjusting the tire pressures to the recommended kPa/PSI. To reactivate the sensors, the vehicle must be driven above 25 mph for at least two min. When the sensors are activated, the driver information center displays the current tire pressures. The EL-52545 tire pressure monitor sensor and RF diagnostic tool may also be used to activate the sensors as well. The BCM has the ability to detect malfunctions within the tire pressure monitor system. In the event a DTC is set, the tire pressure monitor indicator icon on the instrument cluster will flash for approximately one min. and then remain illuminated for the remainder of the key cycle.

After a key cycle and the instrument cluster bulb check has been completed, the indicator will again flash for one min. and then remain illuminated if the DTC persists. Any malfunction detected will cause the driver information center to display a service tire monitor system type message.

TIRE PRESSURE INDICATOR SENSOR LEARN

Special Tools

EL-52545 Tire Pressure Monitor Sensor and RF Diagnostic Tool

Tire Pressure Sensor Learn with EL-52545 (Preferred)

The EL-52545 allows the tire pressure sensors to be learned without transmitting RF data between the sensors and the vehicle.

When using the EL-52545, each tire pressure sensor ID is learned to the EL-52545 and stored internally. The EL-52545 is then connected to the vehicle DLC using the OBD2 Interface Module, which is part of the EL-52545 kit. The stored tire pressure sensor information will then be loaded into the K9 Body Control Module. Using the EL-52545 to learn tire pressure sensors will prevent the vehicle from learning an errant nearby tire pressure sensor from other vehicles in a service facility environment, especially if the tire pressure sensor batteries are low. This is the GM recommended method to learn tire pressure sensors.

1) Turn on EL-52545

2) Select RDR from the on-screen display

NOTE: Make sure the TPMS tool battery is sufficient to complete the learn process. Do not place the TPMS tool directly on the valve stem. The tool should be placed against the tire sidewall near the valve stem. The sensor learn activation procedure may have to be repeated up to three times before determining a sensor is malfunctioning.

3) If available, scan the QR code on the vehicle's tire placard or certification label. If QR is not available, select MMY from the on-screen display and manually input the vehicle information.

4) Approach the vehicle starting with the left front tire and read each tire pressure sensor information by pressing the green trigger button with the EL-52545 located near the tire valve stem. Read each tire pressure sensor in the order identified on the EL-52545.

• If any tire pressure sensors do not respond, replace the tire pressure sensor only after several attempts have been made to identify all sensors. An undetected sensor will be identified with "no sensor detected" displayed in the table. After sensor replacement rerun RDR procedure. Go to next step once all tire pressure sensors respond.

5) Verify the BAT value for each tire pressure sensor in the table on the EL-52545 is OK.

• If not OK, replace the tire pressure sensor and rerun RDR procedure. Go to next step once all are OK.

6) Verify the pressure and temperature values are reasonable based on the ambient conditions and actual tire pressure.

• If either value is inaccurate, replace the tire pressure sensor and rerun RDR procedure. Go to next step once both values are accurate.

7) Ignition On/Vehicle in Service Mode.

8) Connect the EL-52545 OBD2 Interface Module to the EL-52545.

9) Verify the OBDII icon is displayed on the EL-52545 and the green com LED is flashing on the EL-52545 OBD2 Interface Module.

10) Connect the other end of the OBD2 Interface Module to the vehicle DLC.

11) Select OK on the EL-52545 and follow the on-screen instructions.

Tire Pressure Sensor Learn with EL-50448 (Alternative)

When EL-50448 Tire Pressure Monitor Sensor Activation Tool is used in activate mode, it produces a low frequency transmission that activates the sensor. The sensor responds to a low frequency activation by transmitting in Learn Mode-Remotely Triggered. When the BCM receives a learn mode transmission while in learn mode, it will assign that sensors ID to the location on the vehicle relative to the order in which it was learned.

NOTE: In the event a particular sensor is activated and the horn does not chirp, it may be necessary to rotate the wheel so that the valve stem is in a different position because the sensor signal is being blocked by another component. Make sure the TPMS tool battery is sufficient to complete the learn process. Do not place the TPMS tool directly on the valve stem. The tool should be placed against the tire sidewall near the valve stem. The TPMS sensor learn activation procedure may have to be repeated up to three times before determining a sensor is malfunctioning.

1) Ignition On/Vehicle in Service Mode, using driver information center buttons, initiate the Tire Pressure Sensors Learn mode. A double horn chirp will sound indicating the learn mode has been enabled. The left front turn signal will also be illuminated.

2) Starting with the left front tire, activate the sensor by holding the antenna of the tire pressure monitor activation tool aimed upward against the tire sidewall close to the wheel at the valve stem location. Press and release the activate button. Ensure that the transmit indicator on the tool indicates the sensor activation signal is being transmitted.

Wait for a horn chirp. If the horn does not chirp, repeat the sensor activation sequence with the tool. Once the horn chirp has sounded, the sensor information is learned and the turn signal in the next location to be learned will illuminate.

3) After the horn chirp has sounded and the right front turn signal is illuminated, repeat step three for the remaining three sensors in the following order: right front, right rear, left rear.

4) When the left rear sensor has been learned and a double horn chirp has sounded, the learn process is complete and the BCM exits the learn mode.

TIRE PRESSURE SENSOR REMOVAL AND INSTALLATION

Single use fasteners and components include the tire pressure indicator sensor bolt and tire valve front and rear stem.

Removal Procedure

1) Raise and support the vehicle.

2) Remove the tire and wheel assembly.

3) Demount the tire from the wheel.

4) Insert an anti-rotation pin through the cross-drilled hole in the valve stem.

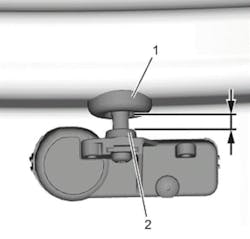

5) Hold the valve stem (3) to prevent it from rotating, then remove and discard the bolt (1) from the tire pressure indicator sensor (2).

NOTE: Do not twist the tire pressure indicator sensor to remove.

6) Pull the tire pressure indicator sensor straight off the valve stem.

7) Cut the inner seal off the valve stem.

CAUTION: Do not scratch or damage the clear coating on aluminum wheels with the tire changing equipment. Scratching the clear coating could cause the aluminum wheel to corrode and the clear coating to peel from the wheel.

8) Remove and discard the valve stem by pulling it through the wheel using a valve stem removal tool.

9) Clean all sealing surfaces.

Installation Procedure

NOTE: The tire pressure indicator sensor is supplied assembled to a new valve stem. They must be separated before installation.

1) Remove the new bolt from the tire pressure indicator sensor (2) and pull it straight off the new valve stem.

2) Apply lubricant to the new valve stem.

NOTE: Valve stems and bolts are single use items.

3) Using a tire pressure valve stem mounting tool, pull the valve stem through in a direction parallel to the valve hole on the wheel.

NOTE: Ensure the flat surfaces of the tire pressure indicator sensor and the tire pressure valve stem are located correctly.

4) Rotate the valve stem by hand to align the tire pressure indicator sensor.

NOTE: Do not tighten the bolt at this stage.

5) Assemble the tire pressure indicator sensor to the valve stem and install the new bolt hand tight.

6) Insert an anti-rotation pin through the cross-drilled hole in the valve stem.

CAUTION: Use the correct fastener in the correct location. Replacement fasteners must be the correct part number for that application. Do not use paints, lubricants or corrosion inhibitors on fasteners, or fastener joint surfaces, unless specified. These coatings affect fastener torque and joint clamping force and may damage the fastener. Use the correct tightening sequence and specifications when installing fasteners in order to avoid damage to parts and systems. When using fasteners that are threaded directly into plastic, use extreme care not to strip the mating plastic part(s). Use hand tools only, and do not use any kind of impact or power tools. Fastener should be hand tightened, fully seated and not stripped.

7) Hold the valve stem to prevent it from rotating and tighten the bolt to 1.4 N.m (12.4 lb in).

8) Check the valve stem to ensure that it is fully seated on the wheel. The wheel hole edge has to be completely in the notch of the valve stem. The valve and the wheel hole have to be concentric.

9) Make sure that there is a parallel gap between the valve stem and the tire pressure indicator sensor.

NOTE: The tire pressure indicator sensor must not be in contact with the wheel.

10) When correctly positioned there will be a parallel gap between the tire pressure indicator sensor and the wheel.

NOTE:

• Tire pressure indicator sensors are shipped in the off mode. The sensor will exit its off state when the tire is inflated.

• The tire should not have contact with the tire pressure indicator sensor during installation to prevent damage to the tire pressure indicator sensor.

11) Mount the tire to the wheel.

12) Install the tire and wheel assembly.

13) Remove the support and lower the vehicle.

14) Perform the tire pressure indicator sensor learn procedure.

TORQUE SPECIFICATIONS

Single Use Threaded Fastener/Component Tightening Specifications

NOTE: All fasteners/components listed MUST BE DISCARDED and replaced with NEW after removal.

Application Specification Metric (English)

Tire Pressure Indicator Sensor Bolt 1.4 N.m (12.4 lb in)

Information for this column comes from the tire pressure monitoring systems data in ProDemand, Mitchell 1’s auto repair information software for domestic and import vehicles. Headquartered in San Diego, Mitchell 1 has provided quality repair information solutions to the automotive industry since 1918. For more information, visit www.mitchell1.com.

About the Author

Mitchell 1

Information for this column comes from the tire pressure monitoring systems data in ProDemand, Mitchell 1's auto repair information software for domestic and import vehicles. Headquartered in San Diego, Mitchell 1 has provided quality repair information solutions to the automotive industry since 1918. For more information, visit www.mitchell1.com.