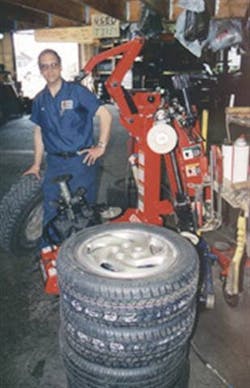

Bob Barnes is an expert at solving vibration problems. His knowledge stems from a combination of reading ("I read everything I can get my hands on"), trial and error ("If I try something and it doesn't work, I try something else") and an inventive mind.

As you can see, common sense may be his biggest asset. The owner of Barnes Garage Inc., a one-outlet tire dealership in Bedford, Pa., Barnes knows there are only so many parts of a vehicle that shake. He simply eliminates the potential problem areas one by one.

Family-owned

Barnes' grandfather started the business as Barnes & Karns in the 1920s. It used to be a Nash dealership. The business hasn't changed much in 80 years; although it no longer sells gasoline, it still offers undercar service, some under-hood service that affects drivability and, of course, tires. "It always sold tires," says Barnes, who took over for his father full-time in 1974. He stocks the Kelly, Star, Regal and Mastercraft brands. He also buys Goodyear and Michelin from a local wholesaler ("I'll stock them if I get a deal").

But the dealership's claim to fame, at least as long as Barnes can remember, always has been alignment and balancing -- even before noise, vibration and harshness was lumped together as NVH.

"It was something we were always known for. As a teenager, I was balancing tires and wheels on a Bear Model 36 spin balancer, and it evolved from there."

As technology changed, so did the source of vibration problems. When drum brakes were replaced by disc brakes, for example, "some of the early rotors weren't balanced perfectly."

In the 1970s, hubcaps often weighed a lot more than they do today. "You experienced vibration with them on the car, but not off," he says.

Word of his expertise spread. "People started coming from 30 and 40 miles away in any direction."

Properly equipped

Barnes invested in the latest technology as it came out. Remember the Alemite on-the-vehicle balancers built by Stewart Warner? He purchased four. Although he added more sophisticated equipment over time, he still used them extensively until 1990. All four still function.

"I still use them as a reference," he says. "I still use the truck balancer for front wheels on tractors."

As long as it serves a purpose, Barnes doesn't throw away any piece of equipment. "I can still fix my old equipment because I saw what was breaking on these things and bought extra parts, everything from 'brain boxes' to strobe lights." Only the Bear Model 36 spin balancer is missing.

Today, he uses a Hunter GSP9700 heavily, often with a Haweka Master Flange Plate set. "I mostly use flange plates with everything because I get my best results with them. Otherwise the center hole in the wheel can be off a few thousandths of an inch. You might use cones with hubcentric wheels, but I've had better results with the flange plate assembly. I get fewer comebacks."

His Bee Line eight laser alignment system was built to his specifications ("a normal Bee Line automotive alignment system doesn't have a calibration bench, so I had them build one").

Checklist

Barnes has car dealerships bring him both new and used vehicles with vibration problems they can't handle. That includes General Motors, Ford and Chrysler dealers. "I had a GM dealer call and tell me he found out about me on GM's Technical Assistance Web page," he says. A Chrysler dealer from 90 miles away recently brought in a Chrysler 300M the dealer couldn't figure out.

"There was a lot of corrosion around the bead seat area of the wheel, and a lot of corrosion on the back of the wheel where it mounted to the hub. So after dismounting the tires and cleaning the bead seat areas, cleaning the back of the wheels, balancing the wheels with a split-weight feature on the 9700 and properly torquing the wheels, the problem was fixed."

Barnes says he has a routine he goes through to decide if it's a brake vibration, driveline problem or a tire wheel vibration.

1. Listen. "If someone calls or comes in and says the car is shaking, I'll ask a series of questions. Does it vibrate when the brake is on? Was it vibrating when you were pushing on the gas pedal or going up a hill? Was it vibrating on the road at speed? Most of the time, I can figure out the problem over the phone. If you make sense to me, and I know what you're talking about, then I know what the problem is."

2. Road test. "If I've driven it, and it feels like tire and wheel assembly shake, I take out my tire pressure gauge and take the tires down to 20 psi all the way around and go for a quick ride. This helps me determine if it's a balance problem or a force variation problem. When you drop the air and the shake changes, you know it's a force variation problem because when you drop air pressure, you lower force variation. Also, force variation can excite the driveline."

3. Jack up the back. "If it's a rear-wheel drive vehicle, I come back to the shop and raise up the end with jacks under the rear housing. Then I get into the vehicle and run it with the tires off the ground, which eliminates force variation. I head to the back first because engine weight will camouflage some force variation problems.

"If the shake stops, you know it's a force variation problem, which can excite the driveline. If it's still there, it's either a tire/wheel assembly or driveline problem. But experienced people will know which because the driveline shake is much faster."

4. Check for irregular wear. "If I verify I don't have a driveline problem, I look for a tire and wheel problem. Obviously, if there are irregular wear patterns on the tires, I don't go any further. I recommend new tires, balanced and aligned."

5. Matching harmonics. "When dealers send me new vehicles, there are no problems with irregular wear. If there is no driveline problem, I'm working with force variation and balancing problems.

"So I go to GSP9700. I try to match the force variation numbers to the lowest possible number. I match the first harmonic high spot of the tire to the first harmonic low spot."

Example: Chevy S-10

Barnes is working with a local Chevrolet dealership to work out some problems on a number of new Chevy S-10s. The vehicles only have a few hundred miles on them.

"We started with the tires," he says. "I started with four new ones; only one had force variation numbers in spec. So I sent the other three back.

"I received three more and returned two. Then I got two more and gave one back. They sent me another and I sent that one back.

"Finally, they sent me one that gave me four tires in spec."

Once the force variation numbers in the tires met proper specifications, he balanced them with the GSP9700 and its split-weight feature (two inside weights and two outside weights). "It eliminates the blinding and rounding to the nearest quarter and gives you an exact balance." Then he put the automotive formula of Equal in them to "to compensate for the force variation that's left. Temperature, air pressure and load significantly change force variation."

Barnes was sent only the tires and wheels, not the vehicle, so he had no answer for the dealer when the drivers still complained. "The problem sometimes is not the vehicle, it's the person driving. They expect too much out of a truck."