QUESTION: What is the best way to reduce stubble damage?

Ralf Krieger, head of development and industrialization of agricultural tires, Continental Tire the Americas LLC: There are several trends in modern agriculture that increase the risk of stubble damage.

The modern plant breeding process is much faster with genetic engineering. The goal to have a more stable plant that is resistant against windstorms and pests leads to a very firm plant structure.

To extend the yield of the feed harvest or biogas production, the plant cutting height is reduced year by year. The remaining stubble is shorter and not easy to tumble over.

The fight against pests, like the corn moth, also demands a low cutting height.

The potential on the tire side is limited by the need to balance flexibility and protection. A good strategy is to bend the stubble before it can penetrate the tire.

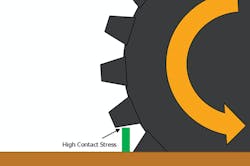

Depending on the size, structure and geometry of the tread pattern, the stubble is clamped and guided to the tire surface. The result is high contact pressure with the possibility of damage. If the tire survives the first 1,000 hits, more will come and cause cavitation at the rubber surface.

To minimize the risk, the pattern shape can be optimized. A 45 degree orientation of the lugs is better than 23 degrees. A flat slope in front of the lug is better than a steep one.

In addition to tire selection, growers can use a mechanical stubble breaking device which quickly covers the cost of itself.

Scott Sloan, ag product manager/global LSW, Titan International Inc.: Stubble is an ongoing challenge for end users and tire manufacturers. Stubble has become more of an issue over the past couple of decades for many reasons. Seed populations have increased from an average of 24K per acre to almost 55K. Genetics have also improved to enhance plant health against insects and climate conditions. So now is there not only more of them, they are much more robust — so tires are exposed to twice as many plants that are much more likely to damage a tire. On any given year weather conditions like drought and freezing play a huge part in the aggravation of stubble damage. Chopping heads have not helped the situation either, as stalks cut 3 inches to 5 inches do not allow the tires to push the stalk over to minimize penetration into the tire, essentially creating a field of rebar that the tires have to cross.

Tire companies can only do so much with the compound. Everyone says we need to make the compound harder. We work within the “Magic Triangle” when it comes to compounding. The area of the triangle is constant, if the compound is changed to affect a certain physical property, another property of that compound will be affected also.

The tire may not show signs of stubble but the end user will be just as unhappy when the base of the lugs or sidewalls begin to crack out. It’s a delicate balance. It’s not that we aren’t working on it, we are constantly evaluating new compounds to find that balance of stubble resistance and tire longevity and performance.

So what can the grower do? My suggestion to all growers that own any brand of tire is to get something in front of the tractor or combine to knock down the stalks ahead of the tires. Just by doing that they would double or triple the life of the tires. I am a huge advocate of mechanical devices that are attached to the equipment like stompers, rollers or any one of a multitude of products that are out there. A minimal investment now will pay dividends for years.

James Crouch, national agriculture product manager, Alliance Tire Americas Inc.: Stubble damage is a significant challenge for farm tires. It’s gotten worse over the years as seed companies have bred for standability, which has resulted in stiffer, stronger stalks and stubble that can do significant damage to tread rubber and sidewalls.

No tire can eliminate stubble damage, but there are a couple of approaches that can help reduce it.

The first step doesn’t come from a tire company at all. Invest in “stalk stompers” or some type of stalk roller, which are bolt-ons that knock over stubble ahead of your combine tires or tractor tires. The cost of a set of those shoes or sleds to mash down residue is less than the cost of replacing a set of premium farm tires, and it’s worth an hour or two of installation time to prevent having to stop to wait on the local service truck to arrive and fix the flat to get you moving again.When it comes to buying tires, spend the extra money to buy tires with stubble-resistant compounds. Yes, there is a difference. When a manufacturer designs a tire, an important part of the equation is balancing the many ingredients in the rubber compound. Over the past decade or so, the industry has fine-tuned the use of natural and synthetic rubber, elastomers, coupling agents and other ingredients to create compound blends that are more puncture resistant than ever before. The chemical composition of the sidewall rubber and tread rubber are different, and both are uniquely blended to ensure both flexibility and durability. It adds some cost, but saves dramatically on repairs and downtime.

Look for steel belts. That steel provides puncture resistance and has the added benefit of dissipating heat when you’re running at high speed, extending tire life. Aramid, also called Kevlar, also provides excellent puncture resistance.

Once you’ve selected your tires, avoid the old habit of mounting your rear combine tires backwards. People used to do that for a smoother ride, but it accelerates stubble damage. Here’s why: The curved lugs of a combine or tractor tire, oriented correctly, are designed to guide stubble from the centerline of the tire to the outside, minimizing damage. If you turn that lug around, you’re actually capturing stubble from the entire footprint of your tire and channeling it to the center. That will cause a tremendous amount of damage to the lugs, especially at the center, and increase the risk that you’re going to get a puncture.

Mark Turner, senior product marketing manager, agricultural tires, Maxam International Inc.: Stubble damage has become an increasing topic of discussion between farmers over the last decade as new varieties and even hybrid crops have come into the farming arena. These new crops are more resistant to diseases, wind damage and other factors that can affect yield.

One of the ways in which these crops have noticeably changed is the strength of the stalk and this, combined with changing harvesting techniques that leave a much shorter stalk in the ground, have contributed to the increase in stubble damage to tires.

Stubble damage mainly occurs in two ways: either cuts and penetrations to the tread or the sidewall, or through chipping where repeated contact with the stubble causes small chips of rubber to be dislodged from the tread area.

So, what steps can be taken to reduce this type of damage? As with all applications, tire selection is very important. This type of damage occurs when tires are run over rows rather than in between rows; selecting a narrow tire that fits between rows can certainly help here. You can regularly see on wider tires which part of the tire was run over the rows as there is damage to only a small portion of the tread, but even this can sometimes be enough to require the tire to be replaced. There is also an opinion that using radial tires rather than bias type tires can help as they are more flexible and can envelope obstacles better.

Fitting front end attachments known as Stalk or Stubble Stompers that push over the stalks before they contact the tire can substantially reduce the problem as these change the angle at which the stalk and tire meet each other and severely limit the chance for a penetration to occur.Dave Paulk: manager of field technical services, BKT USA Inc.: Over the past two decades, genetically modified crops (corn, soybeans, cotton, sunflowers, etc.) have been developed to produce higher yields and resist insects. While these new advancements can be beneficial, they don’t come without drawbacks. The stalks on these crops tend to be much harder, and if cut short during harvest, can damage tires. They become like pieces of steel sticking up in a field.

As we all know, the main components of tires are rubber and fabric. Like other types of rubber, tires can only take a limited amount of abuse before failing. As rubber ages, it hardens and makes the tire more resistant to stubble damage.

You may be wondering, “Why don’t manufacturers make these tires with harder compounds to resist stubble?” In reality, there is a narrow line to walk when compounding rubber for agricultural tires. What works well and improves the tire in one area can cause problems and failures in another. The longevity of the tire and traction must also be taken into consideration. If possible, farmers should cut stalks a little higher than they would usually. This would allow the tires to push the stalks over instead of running directly over them.

There are a number of attachments that can be purchased to fit on combine heads or mount on the front of tractors to do this job. Some examples are the Stalk Crusher (for combines) and Stubble Stomper (for tractors). While these attachments require an initial investment, they will save money in the long run.

Norberto Herbener, OE applications engineer, Trelleborg Wheel Systems Americas Inc.: Stubble damage will always be present in a larger or smaller scale, and is mostly influenced by the way farmers work in the field. Depending on the crop, usually the damage is more cosmetic and doesn’t influence tire performance — wheat stubble damage, for example. On the other hand, corn, soybean or cotton stubble can create significant tire damage.

Several points, independent of the crop or soil type and condition, should be considered when choosing wheel-tire size, design or special features.

1. The first point is tire quality and design. Choose a brand that has: a low warranty rate (talk to your local tire dealer and neighborhood farmers for references); the longest warranty in years, including several years of stubble damage coverage; and the availability and service options… the local tire dealer carries. Most brands offer a dealer locator on their web page as reference.

2. The second point is choosing tires with the largest balloon ratio possible: the second number (in) 480/80R50 has an 80% ratio, for example, as the tire balloon will be taller and carry more air. Also, a taller sidewall — especially on tires with flexible sidewalls — allows for a larger sidewall bulge, which increases the footprint and reduces compaction.

3. Finally, check the design and quality of the rim. If the rim quality is poor or it’s damaged, it is possible that the tire will have issues and not be able to perform as it was designed.

David Graden: operational agriculture market manager, Michelin North America Inc.: Throughout my time in ag sales with Michelin, I have seen a lot of stubble and the corresponding damage it can cause to tires. However, there have been relatively few times I have met with a producer where stubble damage was top of mind. When I ask about the stubble I see on their tires, the response I typically get is something along the line of, “It’s just the cost of doing business.”

Unfortunately, as crops grow taller, stronger, and produce more yield, stubble damage will become a greater concern for the farmer.

Today, there are many different methods for combating stubble. There are rollers, stubble stompers, homemade devices, burning, and more. While many of these will achieve the objective, the unfortunate side effect is that these solutions come at an additional cost and a little frustration. Furthermore, these methodologies can be time consuming and require periodic maintenance, and in the worst case, your tires may still see damage caused by stubble.

In summary, the first and lowest cost approach to reduce stubble is to purchase the right tire, with the right rubber compound and right sweeping 45 degree lug design. As a backup plan, if your stubble damage is persistent, a mechanical device may be a sound investment.

Bradley Harris, manager, global agricultural field engineering, Firestone Ag Division, Bridgestone Americas Tire Operations LLC: As a farmer myself, I see crop stubble becoming more and more of an issue for tires. In the past, it was common to get complaints from growers about driving over corn or cotton stalks resulting in tire punctures. As crop genetics improve and growers focus on agronomics, additional crops like soybeans and cereal grains are now leading to tire damage. Growing up, grandpa and dad would drill soybeans at a population rate of 200K to 220K, and the stalks would have a maximum stalk diameter of 3/16-inch. Today, agronomists are suggesting rolling back those seeding rates to allow the soybeans to bush out. When I measured the stalk diameter of a soybean field planted at 140K population rate, the diameter ranged from 1/4- to 1/2-inch.

Stubble can be managed in a variety of ways, from something as simple as not driving directly over the stubble, to installing a stubble-deflecting device. I encourage customers with stubble problems to install stubble prevention equipment on the corn head or platform to push the stubble down while harvesting. If the customer cannot install stubble deflectors on the heads, there are nice stubble deflection devices that attach to the front of a tractor. Customers do not have to spend a lot of money on stubble deflection devices, the device can be custom made. ■

James Tuschner has spent 25 years in the tire industry, primarily focused on the agricultural and specialty tire markets. His experience includes time spent at Alliance Tire Americas Inc. (first as director of marketing, then as director of business development) and Denman Tire Corp. He started www.agtiretalk.com in 2016.