If a consumer tire has a tread depth of 2/32nds-inch, is it safe to drive on it? Ever since The Tire Rack began running its 2007 video supporting a minimum 4/32nds-inch tread depth, the question of safety has become a topic for debate.

No one in the industry is claiming there is a considerable difference between the two tread depths on dry road surfaces. Based on its own wet-skid testing, however, Tire Rack says 4/32nds is measurably safer than 2/32nds.

In contrast, Michelin North America Inc. claims there is no statistical data that proves 4/32nds will lead to fewer accidents and fatalities than 2/32nds. If anything, available data, which is scarce, indicates little difference.

Both parties accept Tire Rack’s test results. But the debate within the industry continues.

[PAGEBREAK]

Government involvement

According to the federal government, passenger and light truck tires need to be replaced at the 2/32nds-inch mark. That’s the depth at which Federal Motor Vehicle Safety Standards 571.109 (bias-ply), 571.139 (radial) and, in the case of a vehicle with a gross vehicle weight of more than 10,000 pounds, 571.119 require manufacturers to build in tire tread wear indicators.

”Except in the case of tires with a 12-inch or smaller rim diameter, each tire shall have not less than six tread wear indicators spaced approximately equally around the circumference of the tire that enable a person inspecting the tire to determine visually whether the tire has worn to a tread depth of one sixteenth of an inch. (571.139 S5.4)

However, there is no federal standard that labels 2/32nds-inch as the minimum allowable tread depth. Two states, including California, have a minimum of 1/32-inch. Six states have no minimum. The remaining 42 states have a minimum of 2/32nds.

In 1996, the National Highway Traffic Safety Administration (NHTSA) considered a proposal calling for a minimum 3/32nds-inch tread depth standard. In Vol. 61, No. 20 of the “Federal Register,” NHTSA emphatically denied the petition: “NHTSA knows of no data suggesting either a safety or an environmental need to raise the tread wear indicators to 3/32-inch.”

Karen Aldana, a public affairs specialist for NHTSA, says the government is not looking at the issue. In addition, no petition has been filed to change the tread depth for tread wear indicators.

A quarter: the new penny

A wet-skid video out of Europe led Tire Rack to perform its own testing in order to “provide better guidance to consumers,” says Vice President Matt Edmonds. John Rastetter, director of tire information services, supervised the tests, which compared new tires with 10/32nds-inch tread depth, and worn tires with 4/32nds-inch and 2/32nds-inch tread depth, respectively.

Two 2006 vehicles were used: a BMW 325i and a Ford F-150 Super Cab. Michelin Energy MXV4 Plus tires, size 205/55HR16, were chosen for the BMW. Continental ContiTrac tires, size P255/65R17, were chosen for the F-150.

[PAGEBREAK]

The stopping results, in feet, for the vehicles driven on a wet asphalt test track (5/100ths- to 6/100ths-inch of water, enough to flow around, not cover, a dime) at 70 mph were significantly different:

Tread depth -- BMW -- Ford F-150

New -- 195.2 -- 255.1

4/32nds -- 290 -- 377.8

2/32nds -- 378.8 -- 499.5

Rastetter says the BMW, on tires with 2/32nds-inch tread, was still going 44 mph when it passed the point where the tires with 4/32nds-inch tread stopped. With the F-150 on tires with 2/32nds-inch tread, the vehicle was still going 47 mph at the same comparative point.

Based on its results, Tire Rack stops short of saying 2/32nds-inch tires aren’t safe. They just aren’t nearly as safe, which is why it recommends changing tires at the 4/32nds mark. “Ultimately it’s the driver’s decision,” says Edmonds.

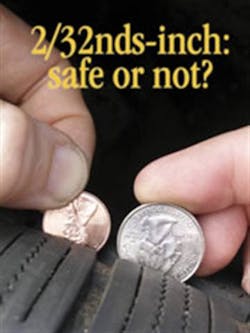

Tire Rack suggests testing tread depth with a quarter rather than the traditional penny. The top of George Washington’s head represents 4/32nds-inch; the top of Abe Lincoln’s head on the penny represents 2/32nds-inch.

Despite its findings, Tire Rack is not calling for a mandate from the government. As Edmonds says, “Do you really want ‘Big Brother’ to determine when tires are worn out?”

To see a video documenting this test, go to www.tirerack.com/videos/index.jsp?video=5.

Michelin takes a stand

Michelin is the first tire manufacturer to publicly address the 2/32nds- vs. 4/32nds-inch issue. It is against raising the tread wear indicators to 4/32nds.

Mike Wischhusen, director of industry standards and government regulations, acknowledges the results from Tire Rack. Shallower treads have longer braking distances, he says.

[PAGEBREAK]

“The real question is, ‘Does that really have a negative impact on safety?’ Is there any accident data? There’s not. We cannot find any data that says there are more accidents on tires with lower tread depth.”

A lot more than tire tread depth is involved when stopping a vehicle on any wet or dry surface: tire traction, driver reaction time and capability, the vehicle’s weight and speed, the braking system and road conditions. It cannot be assumed that the difference in tread depth will have a negative impact on safety, says Wischhusen.

“Drivers adjust as tires change,” he adds.

At a press briefing earlier this year, Dave Stafford, COO of Michelin Americas Research Co., agreed that wet braking distance gets longer as tread depth goes down. However, he disputed that taking tires out of circulation at 4/32nds-inch rather than 2/32nds-inch will lead to fewer accidents and fatalities.

(See “Michelin will not support a 4/32nds-inch minimum standard,” March 16, 2008, on www.moderntiredealer.com.)

In addition to a lack of statistically valid data supporting a comparative increase in injuries and fatalities, “accident databases indicate a small involvement of tires.”

According to NHTSA’s National Automotive Sampling System/Crashworthiness Data System, tire blowouts or flats cause 0.5% of fatal and non-fatal crashes. The NHTSA Fatal Accident Reporting System reports that tires are a factor in 1.1% of all light vehicle fatal crashes.

In addition, the 2004 German In-Depth Accident Study indicates road safety at 2/32nds compared to 4/32nds is not compromised. Europe follows the metric equivalent of a 2/32nds-inch standard, 1.6 mm.

Stafford said differing vehicles and tire brands also affect stopping distance. So does usage. That’s why braking distance alone is not a good indicator of accident frequency.

Michelin is always concerned with safety, he continued. But with safety not a factor in this debate, other issues must be taken into consideration.

[PAGEBREAK]

For example, the United States alone would require approximately 65 million more tires annually if the minimum standard was set at 4/32nds-inch. That capacity is not available, said Stafford.

The environmental impact also would be negative.

Tires with 2/32nds-inch tread depths have lower rolling resistance than tires with 4/32nds-inch tread depths. Removing tires too soon also would cost the U.S. hundreds of millions of gallons and billions of dollars in fuel. Scrap tire disposal also would increase.

In 2001, NHTSA reported that 9% of cars have at least one tire below 2/32nds-inch, according to Stafford. The emphasis, rather than on setting a minimum 4/32nds-inch standard, should be on enforcement to remove tires below 2/32nds-inch on the road today.

Other opinions

Continental Tire North America Inc. follows the official recommendation of its parent company.

“Continental acknowledges in various forms of communication (Internet, technical data books, customer service publications, etc.) that 1.6 mm (2/32nds-inch) is the most widely accepted minimum tread depth standard at which tires should be removed from service,” says Continental AG. “This standard has been adopted as a regulation by many of the world’s national transportation authorities.

“As an indication to the consumer, there are tread wear indicator bars in the main grooves of the tire that become level with the tread surface at approximately 1.6 mm of remaining tread.

“In addition to acknowledging the above, Continental recommends that all passenger and light truck tires in highway motor vehicle application be removed from service at the following tread depths:

* Summer/high performance, all-season tires = 3 mm (4/32nds-inch).

* Winter tires = 4 mm (5/32nds-inch).

(Tire Rack also recommends greater tread depth for snow: up to 6/32nds-inch. “You have to have volume in the tread for snow,” says Rastetter.)

[PAGEBREAK]

“These recommendations are based upon Continental’s testing as well as real world experience which shows that drivers can maintain the performance potential (e.g., wet grip) of their tires by replacing them before they reach the regulatory minimum tread depth of 1.6 mm. This applies especially to winter tires, for which winter driving properties such as snow traction are significantly reduced at tread depths below 4 mm.”

The responses from Bridgestone Firestone North American Tire LLC and Goodyear Tire & Rubber Co. were less direct.

“Different tread depths perform differently under various service conditions,” says a Bridgestone spokesman.

“While it may be evident that more tread depth is typically better than less tread depth in the snow and on wet surfaces where hydroplaning is a concern, we are still studying the issue of tread depth and whether 4/32nds-inch would be a better overall standard.”

Goodyear said it recognized that the minimum legal tread depth remains at the 2/32nds-inch level. “Nevertheless, many drivers may elect to replace their tires before the tread reaches this level.

“Consumers are urged to visually check tires for signs of low or uneven wear, or to have a tire retailer perform this inspection.”

Cooper Tire & Rubber Co., in an official statement, says it has decided to remain neutral on this issue.

“We see this as a ‘common sense’ issue in that there are variables other than tread depth that contribute to a tire’s stopping ability,” says the company. “Vehicle type, individual driving style, speed, road surface, temperature and water depth are some of the variables that will have a direct impact on stopping distance. We will continue to comply with NHTSA’s tread wear indicator standard at 2/32nds on light vehicle tires.

[PAGEBREAK]

“There are sufficient independent studies and opinions from industry experts to suggest that it may be prudent to change tires when tread depth reaches 4/32nds, especially in wet weather states and dependent on an individual’s driving tendencies. Since we do not have specific data to indicate advocacy in this issue, the only action Cooper will take is to alert dealers that wet stopping distance is enhanced at greater tread depths and, therefore, our dealers may want to recommend removal at a depth other than 2/32nds based on particular driving habits and locale.”

The Rubber Manufacturers Association (RMA) has not taken a position on the tread depth issue, according to Dan Zielinski, senior vice president of public affairs.

“Probably a crucial question to be asked is to what extent would changing a minimum tread depth have on vehicle crashes, injuries and fatalities?” he says. “Stopping distance would likely decrease, but translating that to a measurable safety benefit in terms of crash reductions would probably need to be established.

“At least that’s how a regulatory agency would likely need to consider before moving forward.”

Michelin, Continental, Bridgestone, Cooper and Goodyear are members of the RMA.

Test data... or lack of it

There is not much public test data to support anyone’s claim that fatalities and injuries are more likely at 2/32nds-inch tread depth on wet roads than at 4/32nds.

When it comes to wet skid resistance testing, there is little on that as well. In 1969, Jacques Bajer, then working for Ford Motor Co., published his “Proposal for a Procedure for Evaluating Wet Skid Resistance of a Road-Tire-Vehicle System,” and presented the paper to members of the Society of Automotive Engineers Inc.

The proposal focused on developing an indoor test procedure that would not only meet outdoor testing standards, but also eliminate outdoor testing limitations. For example, car design features and varying weather conditions, particularly high winds and high temperature variations, can make interpreting test results more difficult.

[PAGEBREAK]

However, as part of his proposal, Bajer performed outdoor wet skid testing on two different road surfaces using new and used radial tires. The new tires were broken in; the used tires were cut and buffed until slightly less than 2/32nds-inch tread depth remained.

Based on the results, there was no significant difference between the new and used tires on either surface in the cornering tests. On the braking test, again there was no significant difference at 50 mph; however, there was at 70 mph, with the new tires stopping much more quickly than the used tires.

Bajer, president of Tire Systems Engineering Inc., says the paper “is still a reference for those interested in the safety of tires from the wet skid resistance standpoint.”

2/3nds-inch is safe

Tire manufacturers say tires are designed to perform effectively throughout their useful life -- that means down to the tread wear indicators. Design features often take into account the reduction in tread depth.

It would be a reach to believe that tire performance just drops off from “safe” to “unsafe” when the tread wear bars can be seen. As with the Uniform Tire Quality Grading System’s tread wear ratings and subsequent tread wear warranties, the numbers tend to err on the conservative side.

Still, Michelin declares that tires worn beyond the wear bars “are dangerous.” Nissan North America Inc. says the same thing in its vehicle warranty booklets.

Although it doesn’t have a regulation that addresses the safety aspect of worn tires, NHTSA commented on the issue in its 2001 “Everything Rides on It” tire safety campaign. “In general, tires are not safe and should be replaced when the tread is worn down to 1/16 of an inch.”

Consumer Reports also has addressed the subject. Waiting to remove tires worn to the tread wear indicators “may be too late if you drive in rain or snow,” wrote the magazine in July 2007.

“Based on our tests of new and half-tread-depth tires, you may want to consider replacing the ones on your car or truck closer to the 5/32-inch groove depth that marks the half-tread point on many tires.”

[PAGEBREAK]

Interestingly, the tread wear indicator bars are part of the reason the tires are less safe after 2/32nds-inch. They act like little dams that slow down the evacuation of water.

“Regardless of tread depth,” says Cooper, “consumers have the primary responsibility for the regular care and maintenance of their tires.”

Why 2/32nds-inch? -- The reason is unclear

Tread wear indicator bars were first posed to the government at public hearings held by the Federal Trade Commission in 1965. At the time, there very few radial tires on the roads.

Before there was any government intervention, automobile manufacturers out of Detroit demanded tire wear indicators for 1967 model-year vehicles, and the tire manufacturers complied.

But why 2/32nds-inch? In the October 1966 issue of Modern Tire Dealer, a Goodyear engineer claimed that most tire problems occur within the last 10% of tread life.

The Vehicle Equipment Safety Commission (VESC), with backing from the Rubber Manufacturers Association, set the tread depth for the wear bars at 2/32nds in Regulation VESC-7 in 1971. The Department of Transportation (DOT) followed suit in its own regulations.

In 1975, a study prepared for the DOT’s National Highway Traffic Safety Administration concluded that tires should be replaced when they reach a groove depth of 2/32nds-inch. NHTSA acknowledged that “the ‘rule of thumb’ was to place a penny in the tire groove, and if you could see the top of Lincoln’s head, it was time to replace or retread the tire.”

One engineer involved in the industry at that time was succinct in response to the question: “It certainly didn’t come from the engineering community.”