Inventory management requires a daily focus, according to Dan Brown, senior vice president of procurement for American Tire Distributors.

He says tire size proliferation, the reduction in "safety stock" by the tire manufacturers, and the need for greater forecasting by distributors and retailers alike have changed the face of inventory management in the 21st century.

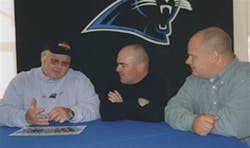

A recent trip to Charlotte, N.C., a hotbed of incoming retailers and strong distributors, proved instructive in the finer points of present-day inventory management at both the wholesale and retail levels. Three major wholesale distributors in the area -- American Tire Distributors (ATD), Target Tire and Automotive Corp. and Carroll Tire Co. -- were willing to share the how's and why's of successfully managing inventory. (In the photo is Chad Slater (center), manager of Parrish Tire Co. of Mt. Airy, N.C., with Tommy Holland (left), American Tire Distributor's general manager in Winston-Salem, N.C., and Parrish Tire salesman Randy Marion.)

American Tire Distributors

"Inventory management is a greater challenge than in the past," says Brown. "Not too long ago, there was plenty of inventory. If you needed it, you'd call and get it. Those days are gone.

"Each of the top three tire manufacturers are more prudent. They've taken a lot of inventory off the floor and re-deployed capital. They're running leaner. They don't have the safety stock in reserve inventory that we're accustomed to."

Tire manufacturers also have shifted some of the responsibility of forecasting to the distributors. "If you're not forecasting, you're going to experience fill-rate issues," says Brown.

"Private branders have always had to provide purchase forecasts to the manufacturer in order to have dependable supply. Today, it has become necessary to provide forecasts for the purchase of the manufacturers' brands as well."

Brown says distributors have to do the following to better serve their customers:

* invest in people and systems for the purpose of supply chain management.

* work more closely with the manufacturers "to better understand production capabilities, possible supply disruptions, plans for new product additions (and) plans to discontinue products."

* make annualized purchase forecasts, updated on a monthly basis.

* replenish product "utilizing sales history and established product screens with designated minimum and maximum inventory levels."

* utilize E.D.I. (electronic data interchange) transmissions.

In the end, however, ATD's fill-rates and product availability "are a reflection of how well the manufacturer is managing their supply to us," says Brown. ATD measures fill rates from its suppliers on a monthly basis.

Because manufacturers are sourcing globally, the lead time in getting its tires can be doubled, he says. "Sizes within the same style might be produced in several different factories, located in different countries around the world. As a result, (manufacturers) cannot respond as quickly to inventory shortages or spike demands."

ATD offers Goodyear, Dunlop, Kelly, Michelin, Uniroyal, BFGoodrich, Bridgestone, Firestone, Kumho, Pirelli, Nitto and Carlisle. It also stocks more than 140 styles of wheels, including its private brand Pacer line.

Target Tire

"Most of the dealers, believe it or not, buy tires every day," says Target Tire's Dave Puckett, vice president and sales manager. "Buying tires every day doesn't require as much room. If you bought everything by brand in trailer load quantities, you'd need 150,000 to 200,000 square feet and you wouldn't have the turns.

"Inventory turns have become so important that you need to buy what your needs are weekly to get the proper turns. We've become a supermarket, so to speak.... Now, everybody carries everything. We've got 12 brands of tires, and you can't buy 12 trailer loads of tires every time you need a tire."

With the help of the TIMS (Time Inventory Management System) from one of its main suppliers, Michelin Americas Small Tires, daily inventory reports can be run automatically. "You can type in the brand based on how many days of inventory you need, and you can set it for what percentage of coverage you want," says Puckett. "TIMS will measure what the needs are for each individual branch. That's the difference in getting 12 turns instead of four or five.

"We still have to buy trailer loads of tires, but there may be four brands on the trailer and it may go to as many as three locations."

Target's 80,000-square-foot Charlotte warehouse runs by line and size. But a new locator system being implemented will set up the inventory by movement. Puckett says the company is in the finishing stages of setting up its first locator system at its warehouse in Columbia, S.C.

Target also does a physical inventory every four months, "which makes you aware of what you have," adds Puckett.

Carroll Tire

"The inventory a wholesale distributor must carry is OE-driven," says Jim Pearl, executive vice president of sales and marketing. "It is estimated by one of our tire suppliers that more than 80% of OE skus in 2004 will have rim sizes of 16 inches or greater, and of this 80%, more than 30% will be 17-inch or greater."

Pearl says Carroll Tire has more than 6,000 skus and 25 different brands, everything from wheelbarrow tires to rear farm tires. Getting the tires to independent dealers when they need them is more difficult today than in the past.

"Dealers today do not keep inventory as they used to. It's a service business, with daily and 'hot shot' deliveries to fill the tire dealers' needs. Managing this inventory monster, maintaining the high fill rate our customers are used to and getting our inventory turns is a challenge."

All three distributors also have business-to-business communication software, which makes each company's entire inventory available to tire dealers 24/7. For ATD it's HeafNet, for Target Tire its Target On-line (with RO Writer point-of-sale software), and for Carroll Tire it's Carroll Tire Online, or CTO.

A four-step approach: How to emphasize inventory management in your dealership

"Achieving 'best-in-class' inventory management begins with education," says Dan Brown, senior vice president of procurement for American Tire Distributors.

"Every employee that has the capability to affect inventory must be educated on the relationship between inventory and the financial performance of the company.

"Management must establish a culture that identifies inventory management as a key business discipline." Brown says the effort to create such a culture should include the following:

1. Establish specific inventory targets and turn objectives by product category or group (consumer tires, commercial tires, agricultural tires, wheels, etc.).

2. Monitor the inventory turns by sku.

3. Identify the products that are slow moving, discontinued or obsolete and put a special effort into disposing of these products.

4. Tie a financial reward or penalty to the compensation program of those with primary control or influence over inventory.

"Having the right inventory at the right time and in the right place is an elusive target," says Brown.