How much is the do-it-for-me preventive maintenance segment of the automotive aftermarket worth? It is a huge, untapped market, according to the Automotive Aftermarket Industry Association, which estimates the market at $62 billion.

It's hard enough convincing consumers to pay for broken parts, much less worn parts, however. Many dealers and their technicians need educating as well. "A shop is only going to sell the things it is comfortable selling," says William "Mac" McGovern, director of marketing and training for KYB America LLC.

Ride (or 'tire') control

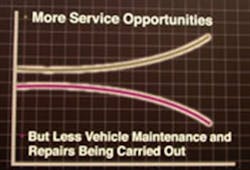

There are more vehicles on the road than ever before. The average age of passenger cars and light truck tires is rising. Annual miles driven nationwide are increasing.

So, how do you take advantage of $62 billion? "That's $700 per day, per technician in lost sales, says Aaron Shaffer, KYB's marketing manager.

"The only way to get someone to buy maintenance is for them to feel it is a goal, such as trying to keep your vehicle fully functional for 200,000 miles," says McGovern, who defines "maintenance" as identifying and replacing worn parts. "There has to be an agreement on need before there is a solution."

[PAGEBREAK]

To help tire dealers with this problem, KYB has developed a "Vehicle Ride Control Exercise Worksheet" that helps a tech compare the car's current condition against the vehicle's capability.

McGovern prefers "tire control" to "ride control" because "it all affects the tires. Tire control is only as good as your weakest component."

In addition to parking lot and highway exercises ("If you're not willing to test drive, we'll shake your hand and move on," says McGovern), there's a visual inspection checklist for tires, suspension products, brakes and struts and shocks. However, the "real power" behind the worksheet is the illustrations of the vehicle condition, says Shaffer.

For the consumer, KYB has point-of-sale materials that explain vehicle control and the need to replace worn parts.

"The key is changing the mindset," says McGovern. "It's not technical training." "The manufacturer and industry don't give dealers enough facts to back up the sale," adds Shaffer.

Training the tech to teach

"Who better to know the difference between failed parts and worn parts than the technician?" says McGovern. "But it's all about failed parts. They do not exit our vocational system knowing about worn parts."

Steve Cartwright, chassis/brake systems curriculum manager for Federal-Mogul Corp., gets the chance to teach experienced and inexperienced techs how to help sell preventive maintenance.

"The first thing I always tell my students is to put themselves in the customer's shoes," says Cartwright. "If you tell (a customer), 'You've got 1/8th of an inch of play in your idler arm, and I need to fix that before I can align your car correctly,' he's going to say, 'Why do I have to do that? It's only 1/8th of an inch of play.' Most customers don't know what an idler arm is." He advocates letting the customer see the worn part, feel it and push on it.

"He'll see the difference in his own mind and see it is deficient, if not broken. Then, bring him back in after you replace it to push on it again and see it is fixed. You won't do a better job of selling the service than that."

[PAGEBREAK]

At least that's the goal, says Cartwright. "You can say you're going to do it every time, but then the shop gets busy and you've got 15 cars backed up."

He also suggests using visual aids such as cutaways or old parts - an idler arm, a tie-rod, a ball joint -- to get your point across.

"Pictures are good, but a lot of customers just won't see what you're talking about until it's on their own car or they have a part in their hand."

If you have to, make your own cutaway. "Take a new part and cut it open. It may be a $60 part, but it could be used to sell 10 more of them."

50,000 miles or bust

In 2004, Tenneco Inc. began promoting a 50,000-mile ride control replacement recommendation based on its research of shock and strut use "under a variety of common driving conditions."

"Shocks and struts wear out very gradually, so drivers might not notice the change in steering, stopping and stability until they are in an emergency situation," said Richard Alameddine, vice president of marketing, at the time.

"By following a 50,000-mile recommended replacement cycle, consumers can enhance these key driving characteristics and help protect the performance of their tires and brakes."

Bill Dennie, director of channel management, says Tenneco hoped to establish a regular interval for shock or strut replacement, like "oil changes every 3,000 miles." Drivers also tend to get a new set of tires around the 50,000-mile mark.

"There's a lot of correlation between worn tires and worn suspension parts." KYB also subscribes to the 50,000-mile recommendation, because by then, most gas or hydraulic shocks and struts no longer provide the handling and control of which your vehicle is capable.

[PAGEBREAK]

In its promotional materials, the company sources a test conducted by the Royal Automotive Club that compares braking performance with shocks at 100% efficiency to shocks at 50% efficiency. It concludes that stopping distance at 60 mph will decrease 11.7% new vs. worn.

"A qualified technician should inspect and road test your vehicle's shocks and struts every year or 12,000 miles," says KYB.

Shaffer says 86% of vehicles in the junkyard still have their original shocks and struts. "When you start going after that 86%, price is not an issue because drivers didn't know they needed it.

"Our ultimate goal is to shift shocks and struts from a repair item to a maintenance item. We can't fight forever for just the 14%."

Off-putting? Just the opposite

Steve Cartwright, chassis/brake systems curriculum manager for Federal-Mogul Corp., advises technicians to do the following when selling preventive maintenance:

1. Put yourself in the customers' shoes.

2. Put the service being done in perspective.

3. Put what needs to be done into words.

The customer is thinking, "What's in it for me?" says Cartwright. For example, if an idler arm needs to be replaced, the tech has to convince the customer that replacing the item will make his tires last longer and improve the vehicle's handling. The customer has to tell himself that making this repair "is an investment in the life of my tires."

[PAGEBREAK]

Selling ride control: Dealers strut their stuff coast-to-coast

In 2005, KYB America LLC initiated its "Ride Control Solutions" campaign to help service providers identify worn ride control units and develop "the tools that service writers can use to effectively communicate the need for ride control service to the customer." Two of its customers have taken advantage of performing preventive maintenance.

On the East Coast, Action-Gator Tire Stores was selling 10 to 15 shocks and struts a month at its Ocoee, Fla., shop prior to implementing Ride Control Solutions from KYB. As a result, Action-Gator's technicians and service writers helped increase the store's shock and strut business by more than 700%, to more than 120 units per month.

According to an Action-Gator spokesman, the technicians "really like all of the illustrations on the worksheet (see photo), and are using the worksheet on each and every road test we do."

On the West Coast, Terry's Automotive Inc. in Olympia, Wash., was moving close to 10 shocks a month. It has increased that almost tenfold.

"Before KYB, no one had actually come into our shop to teach my people how to sell shocks," says owner Terry Holmstrom. "KYB showed us how to properly diagnose worn shocks, how to approach a customer, and how to sell ride control as part of an overall maintenance and safety program."