TPMS: Mitsubishi Outlander and Outlander Sport

Subject vehicles: 2008-2013 Mitsubishi Outlander and 2011-2013 Outlander Sport.

Relearn procedure?: Yes, see reset procedure.

Special tools needed?: Yes, scan tool (MUT-III Sub Assembly); Vehicle Communication Interface; MUT-III USB Cable; and MUT-III Main Harness A.

The tire pressure monitoring system (TPMS) on the 2008-2013 Mitsubishi Outlander and 2011-2013 Outlander Sport uses tire inflation pressure sensors on the wheels to monitor pressures. The system only indicates when a tire is significantly under-inflated. Under the following conditions, the system may not function properly:

* Wheels other than Mitsubishi genuine wheels are being used.

* Wheels that are not fitted with tire pressure sensors are being used.

* Snow or ice is stuck inside the wheel housings and/or on the wheels.

* The tire pressure sensor’s battery is discharged (10-year/100,000-mile life span).

* A wireless facility or device using the same frequency with the tire pressure sensor is near the vehicle.

* Wheels whose tire pressure sensor IDs are not registered by the vehicle are being used.

TPMS warning light

When the ignition switch is in the ON position, the tire pressure warning light will remain illuminated if one or more of the vehicle’s tires (including the full-size spare tire) is under-inflated.

If any of the road wheel tires do not contain a tire pressure sensor and the vehicle is driven, the warning light will flash.

NOTE: The tire pressure warning light may not illuminate immediately in the event of a rapid leak.

When the tire pressure warning light illuminates or does not come on briefly, immediately check air pressure of all tires (including the spare tire) and adjust to specified pressure.

If the warning light is still on after driving for about 10 minutes after adjusting tire pressures, one or more of the tires may be punctured.

If the warning light does not come on at bulb-check, still comes on after adjusting tire pressure, or flashes when all four tires have correct tire pressure sensors, there is a problem with the TPMS. See the appropriate manufacturer service information.

Reset procedures

NOTE: If a TPMS tire pressure sensor, receiver, antenna or feeder cable(s) is replaced, the tire pressure sensors must be registered.

Tire pressure sensor registration

NOTE: When the TPMS transmitter or TPMS receiver are replaced, execute “Tire Pressure Sensor ID Registration.” The TPMS will not function until the “Tire Pressure Sensor ID Registration” has been completed.

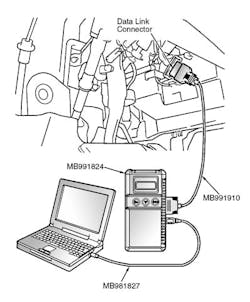

The following tools are used to register the TPMS:

* Scan Tool (MUT-III Sub Assembly) (MB991958).

* Vehicle Communication Interface (VCI) (MB991824).

* MUT-III USB Cable (MB991827).

* MUT-III Main Harness A (MB991910).

CAUTION: To prevent damage to the scan tool (MB991958), always turn the ignition switch OFF before connecting or disconnecting the scan tool.

1) Connect the MUT III scan tool (see Figure 1). Turn the ignition switch to the ON position. From the “Special Functions” screen, select “Tire Pressure Sensor ID Registration.” NOTE: If the ID code registration is not finished within 20 minutes, all the ID codes registered in the TPMS transmitter before will be erased. For this reason, the ID codes need to be registered again.

2) Select “4tires ID Reg. (Change tire PRS.)” and start the tire pressure sensor ID registration.

NOTE: You can start out the operations from any TPMS transmitter. The tire pressure sensor ID registration has no order.

On completion of the TPMS transmitter ID code registration, the TPMS transmitter ID code is displayed on the scan tool screen.

The scan tool cannot identify which registered TPMS transmitter is used for each wheel. For this reason, write down the tire number for each wheel when the tire number and ID code is displayed on the scan tool during ID code registration.

It may take approximately one minute for the ID code to be displayed on the scan tool screen after the tire pressure is reduced.

If the ID code is not displayed, reduce the tire pressure another 20 kPa (2.9 psi) or more. If the ID code is not displayed yet, rotate the tire to displace the TPMS transmitter, and reduce the tire pressure 20 kPa (2.9 psi) or more again.

If the ID code cannot be registered for all four wheels, the KOS-ECU may be faulty, thus replace the KOS-ECU.

If the ID code can be registered for one wheel or more, the TPMS transmitter in which the code cannot be registered may be faulty, thus replace that TPMS transmitter.

3) Decrease the tire pressure to 25.2 psi or less by changing 2.9 psi or more, and register the TPMS transmitter ID code of each wheel to KOS-ECU.

4) When “4 SNSR ID Registration Completed.” is displayed, select “OK.”

5) After one minute or more has passed, correct the tire pressure for all wheels with ignition switch “ON.”

6) Check the data list “Registered ID reception, Tire 1, 2, 3, 4 if “YES” is displayed for each tire. When “NO” is displayed, drive the vehicle for approximately five minutes, check the display again. If “NO” is still displayed, register the ID code again.

NOTE: If the spare tire is removed, always reposition valve as shown in Figure 2. If the valve is not positioned as shown, the system may incorrectly determine the spare tire is a road tire.

Demounting/mounting procedures

CAUTION: The tire should be demounted from the wheel using the tire changer manufacturer’s instructions.

CAUTION: The use of non-genuine wheels may cause the improper installation of tire pressure sensors, possibly resulting in air leakage and damage to the sensor.

NOTE: If the spare tire valve is not positioned as shown, the roll switch (which is incorporated in the tire pressure sensor) may operate. In that case, the system may incorrectly determine the spare tire is a road tire (see Figure 2).

NOTE: Ensure the valve cap is always in place except when adjusting tire pressure. If the valve core and valve cap are replaced, use a genuine replacement part. The valve core is similar to a conventional one, but uses nickel plating to avoid corrosion.

Tire pressure sensor

CAUTION: Do not vary the angle of valve except at mounting on the rim. If varying the angle over and over, it may cause breakage of the antenna plate resulting in the failure of the TPMS transmitter.

Ensure the valve cap is always in place except when adjusting tire pressure.

Replace the seal and seal washer with a new one every five years or when the tire is replaced.

Do not drop the TPMS transmitter from a height greater than 1 meter (3.3 feet).

Do not expose the TPMS transmitter to extraneous magnetic fields. The TPMS transmitter should not be stored at temperatures above 176 degrees Fahrenheit (80 degrees Celsius).

The TPMS transmitter should not be exposed to temperatures above 212 degrees F (100 degrees C).

If the TPMS transmitter is replaced, execute “Tire Pressure Sensor ID Registration” on scan tool MB991958 “Special Function.” See reset procedures.

Be careful not to damage the transmitter.

Removal

1) Raise the vehicle on a suitable support. Remove the tire/wheel assembly from the vehicle.

2) Remove the cap and valve core to deflate the tire. CAUTION: Be careful not to damage the TPMS transmitter.

3) Rotate tire so that valve stem is in the 6 o’clock position, and once tire pressure is released, remove the nut and let the TPMS transmitter fall into the tire (see Figure 3).

4) Place on tire changing machine and break both tire beads ensuring that the TPMS transmitter remains in the bottom of the tire.

5) Lubricate the tire well, and remove the outer side of the tire.

6) Reach inside the tire and remove the tire pressure monitoring sensor.

7) Remove the tire from the rim using the proper tire changing equipment procedures.

8) Hold the TPMS transmitter and the seal washer, and then extract it. This also extracts the seal. Take care to not damage the valve thread.

9) Clean the TPMS transmitter and the valve stem. Take care to support the rear of the valve with a thumb so that there is no movement of the stem.

Installation

1) Mount the tire pressure sensor valve through the rim hole as shown (see Figure 3). Install the valve in the valve hole without modifying the angle of the stem. The laser marking should be visible. When the valve is completely inserted, maintain the TPMS transmitter contact with the rim, and then tighten the nut finger tight. CAUTION: When installing a new seal and seal washer, make sure to support the valve stem base with a thumb so that there is no movement of the stem. Otherwise, the stem may protrude resulting in the breakage of the antenna plate. CAUTION: Visually check that the TPMS transmitter is not deformed or damaged. When installing the TPMS transmitter, be sure the rim, seal valve and nut are clean.

Ensure the grommet is located inside the valve hole before installing the nut.

While installing the nut, push on the TPMS transmitter to maintain contact of the transmitter lower lip with the rim.

While installing the valve nut, ensure the tool is kept aligned to the valve and the valve hole.

After installing the nut, check that the seal is compressed and the seal washer is not bent.

2) Install the seal and washer up to the base of the TPMS transmitter. Wipe the seal and threading.

3) While maintaining the TPMS transmitter contact with the rim by applying pressure to the back of the valve, slightly press on the cap toward the center of the wheel in order to adapt the angle of the valve/TPMS transmitter to the profile of the rim. Maintaining contact with the rim is mandatory (see Figure 4). CAUTION: Install the tire pressure sensor correctly, or it may not work properly or become damaged when the tire is installed.

4) While maintaining the TPMS transmitter and valve in position, screw the nut with a torque wrench. Take care that the wrench socket is correctly inserted on the nut. Tighten the valve nut finger tight, then slowly tighten the valve nut to 45 - 53 in.-lbs. (5 - 6 N.m) as in Figure 5.

5) Place the wheel and tire on the turntable of a tire mounting machine. Ensure that the transmitter is 270 degrees (3 o’clock position) from the mounting head when the outer tire bead is mounted as shown (see Figure 6). Lubricate the tire well, and mount the outer tire bead as normal. Ensure that the tire does not rotate during mounting.

6) Install the tire on the wheel. Install the tire/wheel assembly on the vehicle.

7) Inflate the tire to specification. After tire inflation, retighten the valve nut to 45 - 53 in.-lbs. (5 - 6 N.m). This is necessary, as the tire pressure sensor is secured to the wheel with the valve nut and rubber grommet. The rubber grommet will be depressed by tire pressure or deteriorate over a period of time, which requires the valve nut to be retightened.

8) Register the tire pressure sensor. See tire pressure sensor registration under reset procedures. ■

Information for this column comes from Mitchell 1’s “Tire Pressure Monitoring Systems Guide” for domestic and import vehicles through 2013. Headquartered in Poway, Calif., Mitchell 1 has provided quality repair information solutions to the automotive industry for more than 80 years. For more information, visit the company’s website at www.mitchell1.com.

Want more TPMS articles? See below:

'Train' reolaced sensors on F-150 pickups